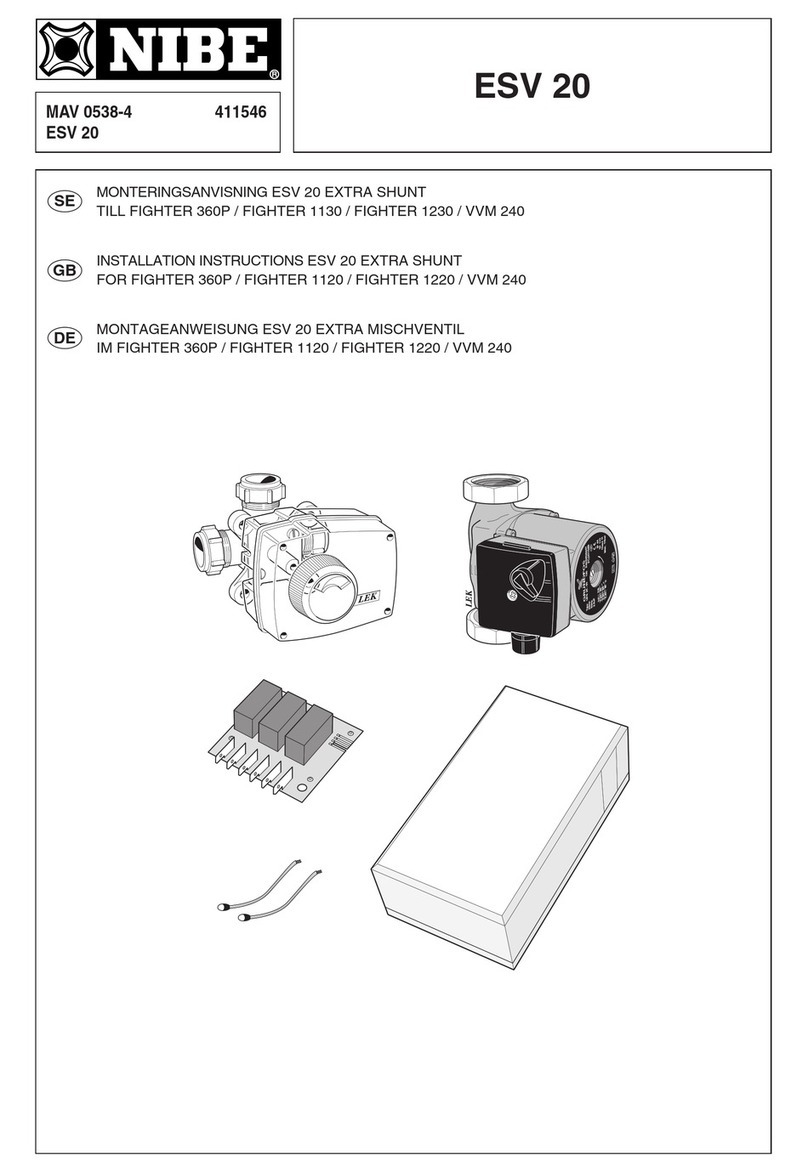

0 ºC

-3 º C

22 ºC

-3 º C 0 ºC

0 ºC

5 ºC-4 ºC

100 ºC

35 ºC25 ºC

Brine

Refrigerant

Evaporator

Condenser

Expansion valve

Compressor

1

2

Heat source

Czynnik obiegu dolnego źródła

Exhaust air module

function

An exhaust air module uses the heat that is in the

building's ventilation air to heat up the brine.

Brine circuit

An anti-freeze liquid (brine) circulates in a hose (collector)

from the heat pump out to the heat source

(rock/ground/lake). The energy from the heat source is

stored by it heating the brine a few degrees, from about

–3 °C to about 0 °C.

A

The collector then routes the brine to the heat pump’s

evaporator. Here, the brine releases heat energy and the

temperature drops a few degrees. The liquid then returns

to the heat source to retrieve energy again.

B

Refrigerant circuit

Another liquid circulates in a closed system in the heat

pump, a refrigerant, which also passes the evaporator.

The refrigerant has a very low boiling point. In the evapor-

ator the refrigerant receives the heat energy from the brine

and starts to boil.

C

The gas that is produced during boiling is routed into an

electrically powered compressor. When the gas is com-

pressed, the pressure increases and the gas’s temperature

increases considerably, from approx. 5°C to approx. 100°C.

D

From the compressor, gas is forced into a heat exchanger,

condenser, where it releases heat energy to the heating

system in the house, whereupon the gas is cooled and

condenses to a liquid form again.

E

As the pressure is still high, the refrigerant can pass an

expansion valve, where the pressure drops so that the

refrigerant returns to its original temperature. The refriger-

ant has now completed a full cycle. It is routed to the

evaporator again and the process is repeated.

F

Heat medium circuit

The heat energy that the refrigerant produces in the con-

denser is retrieved by the climate system's water, heating

medium, which is heated to 35 °C (supply temperature).

G

Ventilation

The hot air is transferred from the rooms to the heat pump

via the exhaust air module.

J

The fan then routes the air to the exhaust air module heat

exchanger. Here, the air releases the heating energy to

the brine and the air's temperature drops significantly. The

cold air is then blown out of the house.

K

The temperatures are only examples and may vary between different installations and time of year.

FLM S45Chapter 2 | The heating installation – the heart of the house6

2 The heating installation – the

heart of the house