Nibe SAM 40 User guide

Other Nibe Fan manuals

Nibe

Nibe DVC 10-50 User manual

Nibe

Nibe Contura C500 Style User manual

Nibe

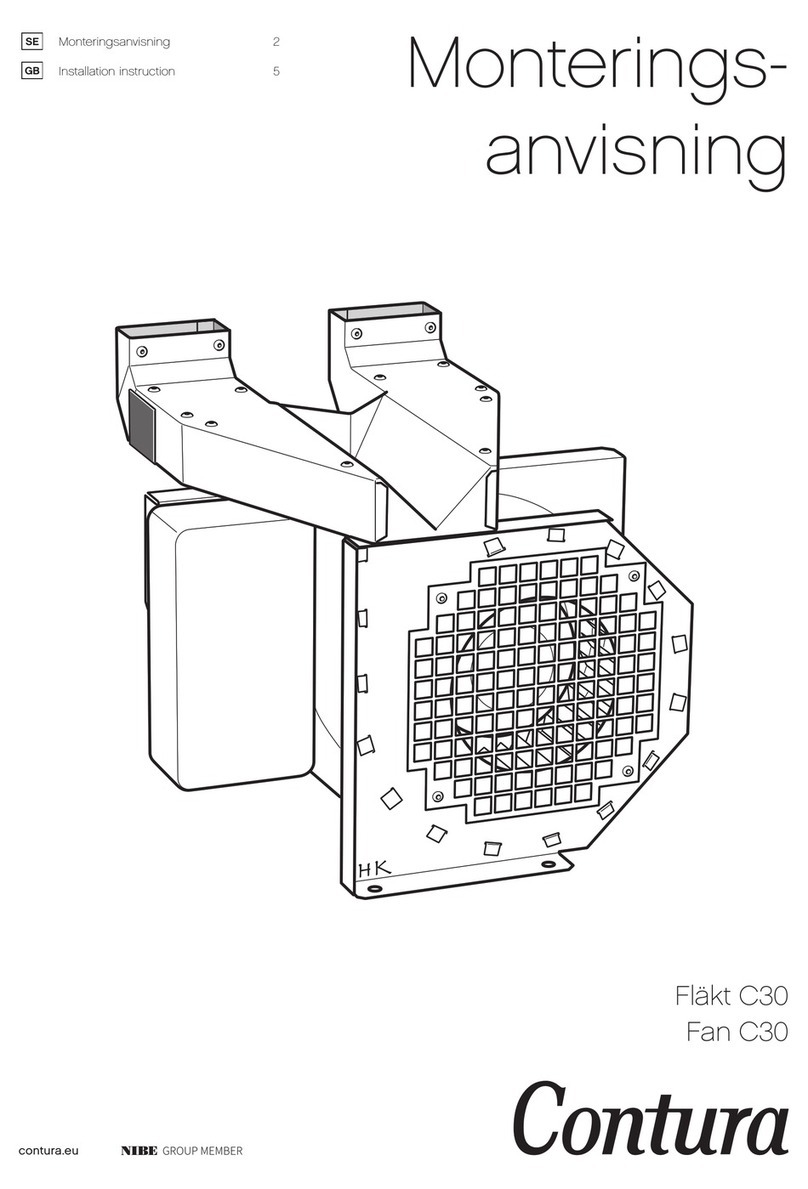

Nibe Contura C30 User manual

Nibe

Nibe GV-HR 120 User guide

Nibe

Nibe Contura C500 Style User manual

Nibe

Nibe ERS 20 User manual

Nibe

Nibe ERS S40-400 User manual

Nibe

Nibe ERS S10-400 User manual

Nibe

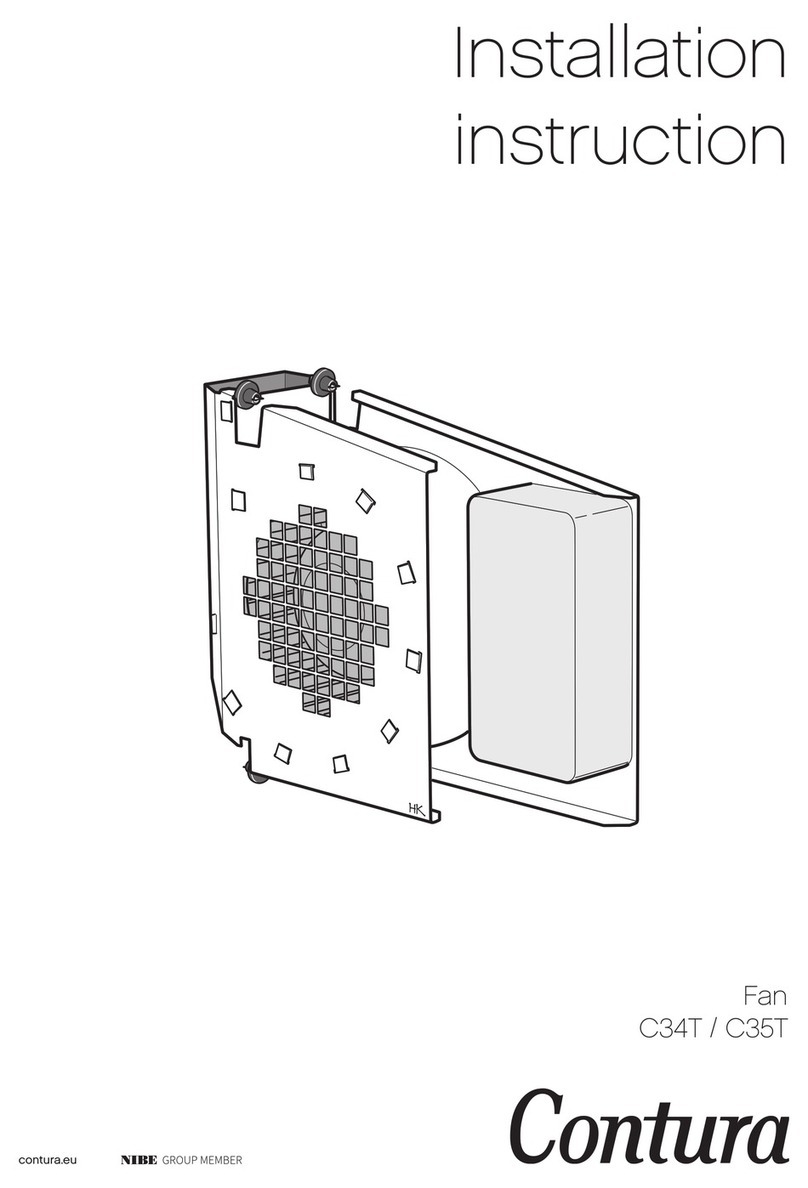

Nibe Contura C34T User manual

Nibe

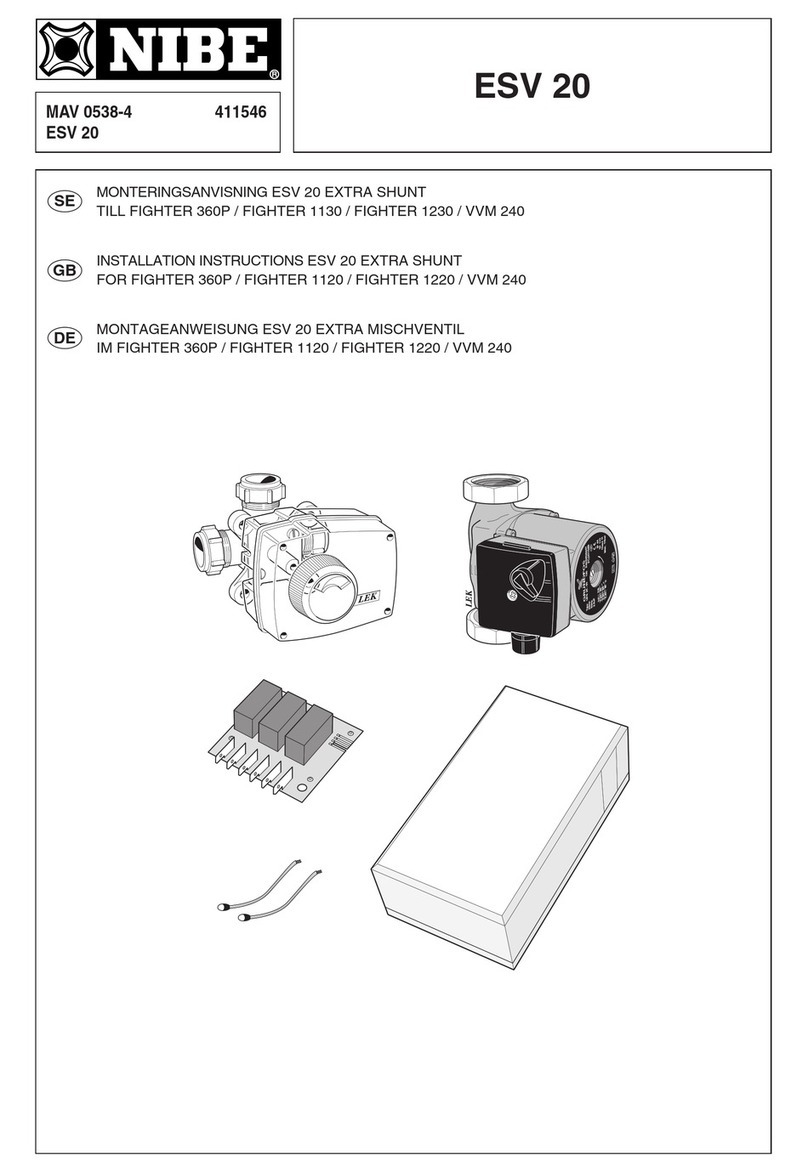

Nibe ESV 20 User manual

Nibe

Nibe SAM 42 User manual

Nibe

Nibe GV-HR 130 User guide

Nibe

Nibe FLM 40 User manual

Nibe

Nibe FLM S45 User manual

Nibe

Nibe ERS 20-250 User guide

Nibe

Nibe ERS S40-350 User guide

Nibe

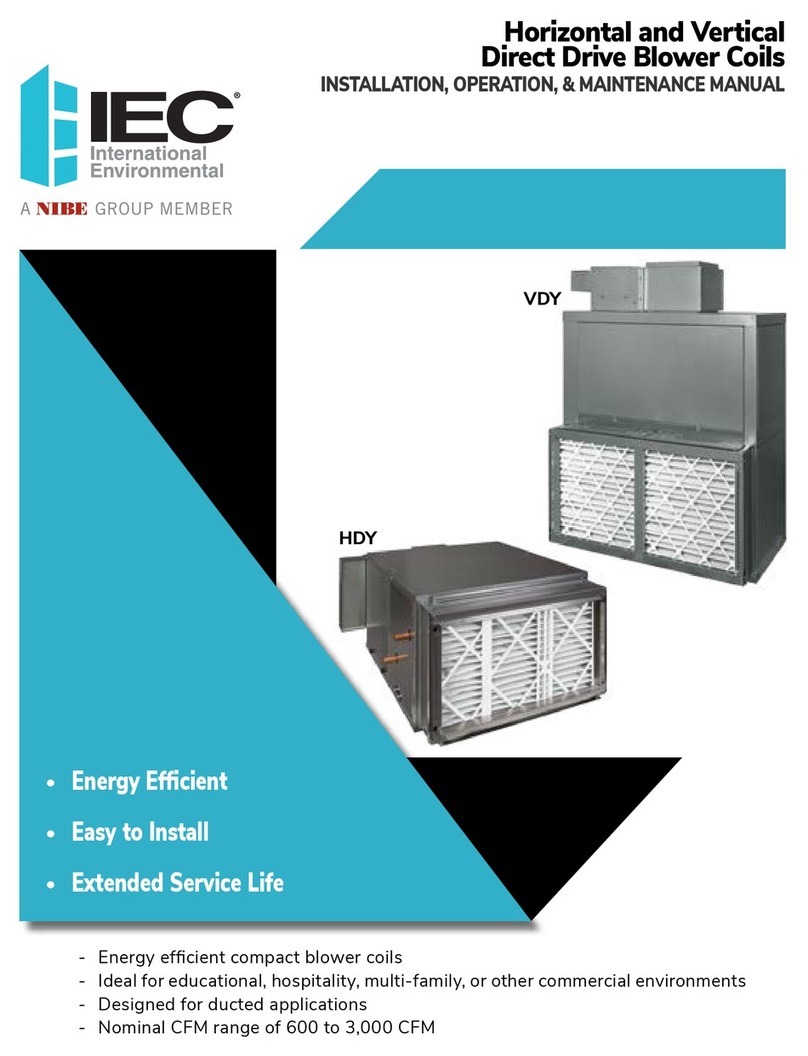

Nibe IEC VDY Instruction manual

Nibe

Nibe FLM S45 User guide

Nibe

Nibe Flakt Contura C600 User manual

Nibe

Nibe ERS S10-400 User guide

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions