V1.0x F

SPECIFICATIONS

Sensor input: User defined. The supported sensors are listed in Table 1,

along with their maximum ranges.

Thermocouples: Types J, K, R, S, T, N, E and B to IEC 60584 (ITS-90).

Impedance >>1 MΩ

Pt100: Excitation: 180 µA, 2 or 3-wire connection (for 2-wire

sensors, tie, terminals 2 and 3 together).

α= 0.00385, according to IEC 60751 (ITS-90).

Voltage: 0 to 50 mVdc, 0 to10 Vdc.Impedance >>1 MΩ.

* Note: 0-10 Vdc input type requires an internal jumper

switching.

0 to 20 mA,4 to 20 mA. Impedance 15.0 Ω(+ 1.9 Vdc).

Sensor Type Range Minimum measurement span

Thermocouple K -150 to 1370 °C / -238 to 2498 ºF 100 °C

Thermocouple J -100 to 760 °C / -148 to 1400 ºF 100 °C

Thermocouple R -50 to 1760 °C / -58 to 3200 ºF 400 °C

Thermocouple S -50 to 1760 °C / -58 to 3200 ºF 400 °C

Thermocouple T -160 to 400 °C / -256 to 752 ºF 100 °C

Thermocouple N -270 to 1300 °C / -454 to 2372 ºF 100 °C

Thermocouple E -90 to 720 °C / -130 to 1328 ºF 100 °C

Thermocouple B 500 to 1820 °C / 932 to 3308 °F 400 °C

Pt100 -200 to 600 °C / -328 to 1112 ºF 40 °C

Voltage 0 to 50 mV 5 mV

* 0 to 10 V 1 V

Current 0 to 20 mA 2 mA

4 to 20 mA 2 mA

Table 1– Transmitter input sensors

Output: 2-wire 4-20 mA, linearwith respect to the measured signal.

Resolution: 0.001 mA (14 bits)

Total Accuracy: Better than 0.3 % of the maximum span for

thermocouplesand 0.2% for Pt100 and voltage;

Response Time: < 500 ms

Isolation: Between the sensor and the 4-20 mA loop (1000V / 1 min).

Power Supply:12 to 35Vdc, across the transmitter;

Maximum Load (RL): RL (max.)= (Vdc – 12) / 0.02 [Ω]

Were: Vdc= Power supplyvoltage

Operating Temperature: -40 to 85 °C

Humidity: 0 to 90 % UR

Electromagnetic Compatibility: EN 50081-2, EN 50082-2

Internal protection against polarity inversion.

Cold junction compensation for thermocouples.

CONFIGURATION

If the transmitter is already configured as required by the application (sensor

type, range, etc), it may be installed and used right away. However, if a

distinct configuration is required, this can be done through the TxConfig

software and the TxConfig Interface.

The TxConfig interface and software can be purchased from the manufacturer

or at its authorized distributors and representatives. Updates for the software

are available at our website. To install the TxConfig software, run the

Tx_setup.exe fileand followtheinstructions.

Serial port configuration errors may occur when other devices are

sharing the same port (ex.: Palm Hot Synch). Close all serial port

applications prior to using the TxConfig software.

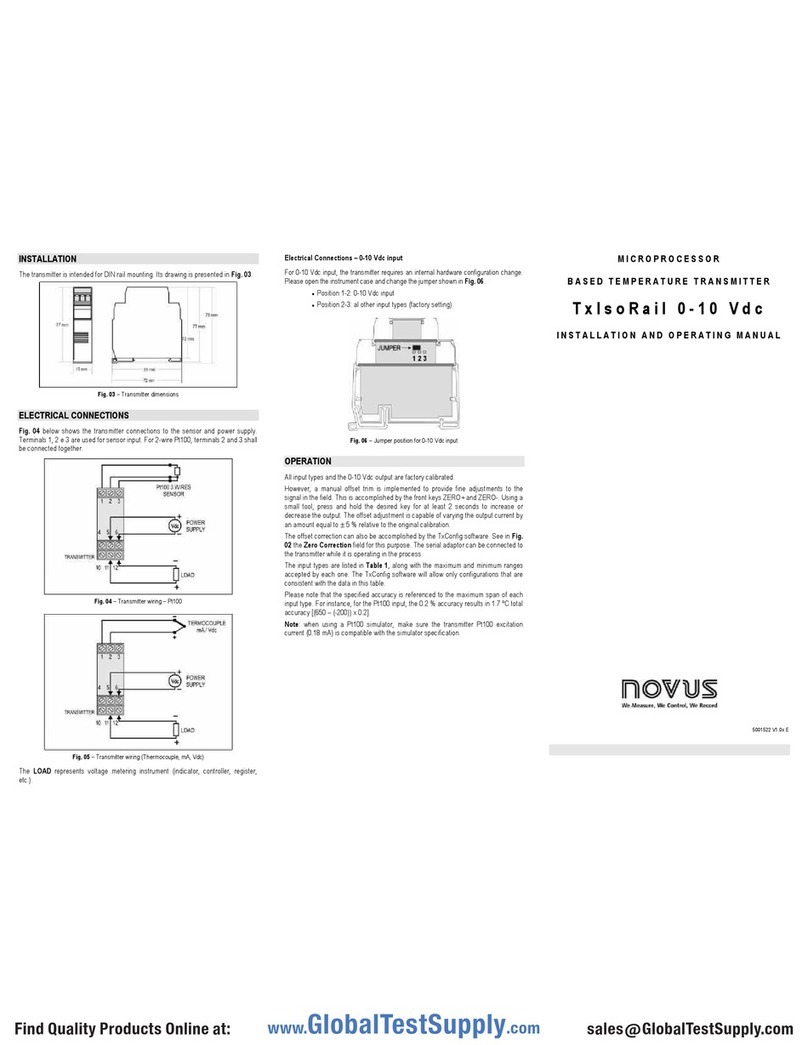

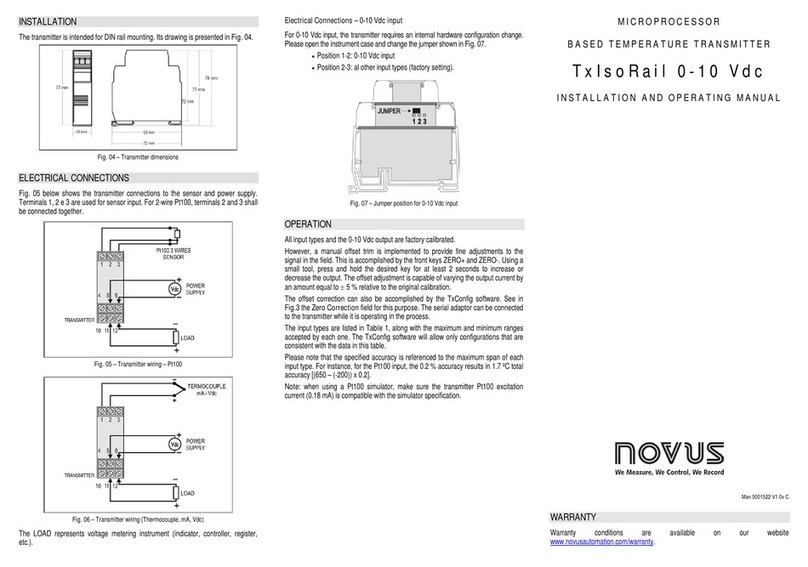

The TxConfig interface connects the transmitter to the PC, as shown in Fig.

1and 2. There are two types of interface: TxConfig-RS232 and TxConfig-

USB.

Fig. 1– TxConfig Interface connections model RS232

Fig. 2– TxConfig Interface USB connections

Once the connection is accomplished, the software shows the configuration

options of the transmitter model attached. Access the Help for usage

instructions.