(Update interval) = 60

In order to configure it for the first time, it is necessary to remove the front cover

and connect it to a computer through a mini-B USB cable. The initial

configurations for wireless are described as follows:

PAN ID (Network Identifier) = 22350 (0x574E)

RF Power (Power Level) = 0 dBm

6.1 RHT-Air SCREENS

Indication screen of the values measured in the device:

1st Screen: Main

In order to configure the communication parameters, you should press the

Button (for about 5 seconds) until it starts to blink, release it and press

it again to expand it. When the expected value appears, release the button

and wait until the screen stops blinking (for about 10 seconds). If you want to

move on to the following screens, press the button .

Configuration screen of the Modbus Address – Sets the address of the

module on the Modbus network. Between 1 and 246.

2nd Screen: Modbus address

Time configuration screen – Sets the update interval.

3rd Screen: Update interval

Mode’s configuration screen – Sets the indication mode.

4th Screen: Indication mode

Configuration screens of the Unit: It sets which temperature unit should be

used (ºC or ºF).

5th Screen: Unit

Screens for viewing the values measured in the device only:

6th Screen: Temperature

7th Screen: Relative Humidity

8th Screen: Dew point

7BATTERY LIFE

The battery is estimated to last for over a year. There is a fine line between its

life and how the device is used. The lower the sensor’s reading interval, the

shorter it will last, as it may, in the worst case scenario, last for 30 days only.

If you wish to save the battery’s energy, it should be set to the lowest interval

possible between updates. The level of transmission power to communicate

with the AirGate-Modbus of the network has an effect on its life, too. So, the

device should be configured to operate under the minimum power and as close

to an AirGate-Modbus of the network as possible.

8WIRELESS

RHT-Air has an IEEE 802.15.4 wireless connection to connect with

AirGates-Modbus that has its firmware updated to a version more recent

than V1.23. The first RHT-Air configuration must be done through a USB

through Software DigiConfig, as the necessary parameters for

communication with AirGates should be set. After the first time it is

configured and matched with a AirGate-Modbus, RHT-Air will operate as a

Modbus RTU slave. From this moment on, all its resources can be accessed

through the reading of its registers in any Modbus RTU site. The

Programming button can be used for configurations.

The information necessary for data reading without DigiConfig can be found

in this item. Software DigiConfig should be used in order to ensure the

device’s correct configuration. After it is configured, its data can be accessed

by any other software with Modbus RTU communication capacity.

7.1 MODBUS COMMANDS

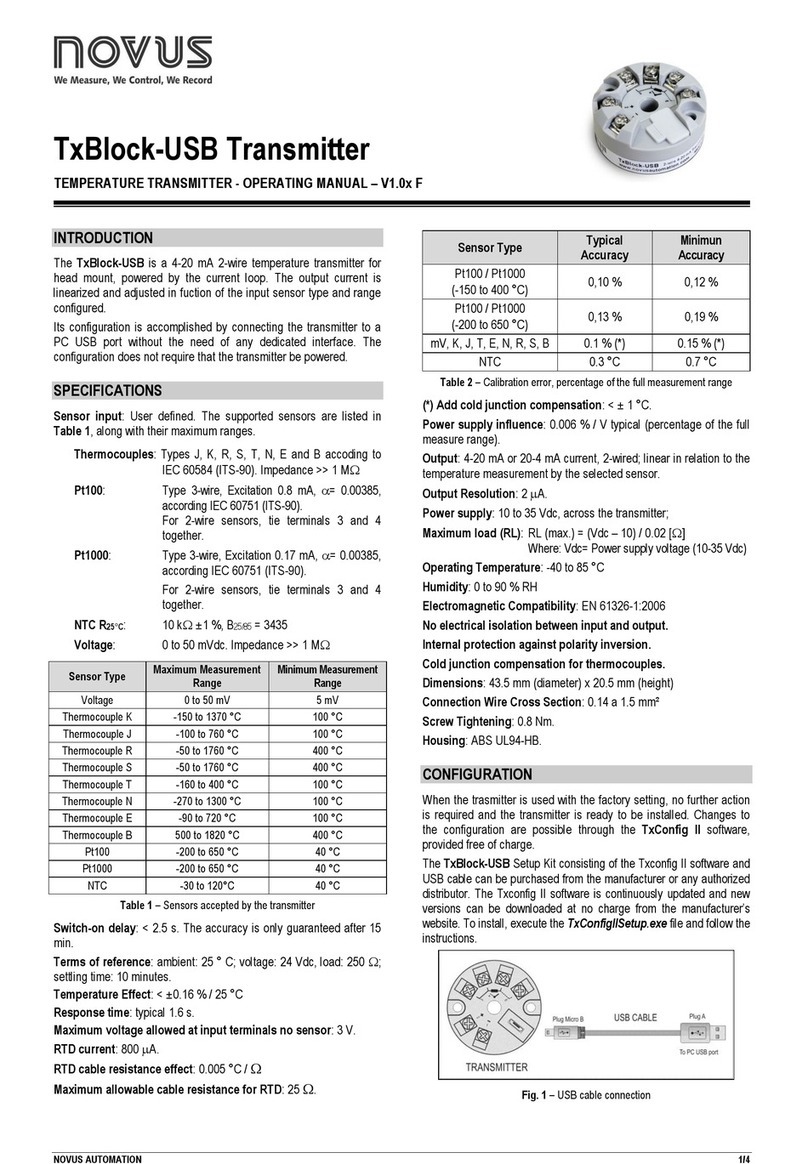

The following Modbus RTU commands (functions) are implemented: For

further information on each one of these functions and on the Modbus

protocol in general, go to www.modbus.org.

READ HOLDING REGISTERS – 0x03

This function can be used to read a value of one or up to 42 retentive

registers, as per the “Retentive Registers Table”.

WRITE HOLDING REGISTERS – 0x06

This function can be used to write in a retentive register, as per the

“Retentive Registers Table”.

7.2 DESCRIPTION OF SOME REGISTERS

Once the RHT-Air meets an AirGate-Modbus and is matched, this AirGate will

be last published by RHT-Air. Therefore, when the Master of the Modbus

network requires that the RH-Air address be read, the response is sent

immediately and the expiration of this publication can be checked through

register 30, which shows how long it has been since the last publication.

REGISTER 6 – PAN ID

A common identifier for each IEEE 802.15.4 wireless network. All machines

from a common network (AirGates-Modbus and RHTs-Air) must be

configured with the same PAN ID

REGISTER 7 – ENCRYPTION

This register should be used to enable or disable the use of encryption. If it

is enabled, the encryption key should be the same used for all device

configured with the same PAN ID.

REGISTER 16 – POWER LEVEL

The power level may be adjusted as needed, according to the variations

presented in the table below: The higher the power set, the higher the reach, but

the higher the consumption. It is suggested that the lowest value possible be

configured, since in the event that RHT-Air is not able to communicate with the

AirGate-Modbus, it will automatically increase the transmission power gradually,

until it is able to communicate with AirGate-Modbus or reach the highest

configurable limit. It may be that this register is configured with a value and, after

some time, this value may be altered to adjust to a communicable power.