NSK Ti-Max X205L User manual

Other NSK Dental Equipment manuals

NSK

NSK SGR2-E User manual

NSK

NSK Ti-Max X95L Use and care manual

NSK

NSK Ti-Max X Series User manual

NSK

NSK G1-E User manual

NSK

NSK Phatelus Series User manual

NSK

NSK CARE 3 PLUS User manual

NSK

NSK Surgic Pro2 User manual

NSK

NSK Surgic Pro Series User manual

NSK

NSK FX15 User manual

NSK

NSK Ti-Max NLX nano User manual

NSK

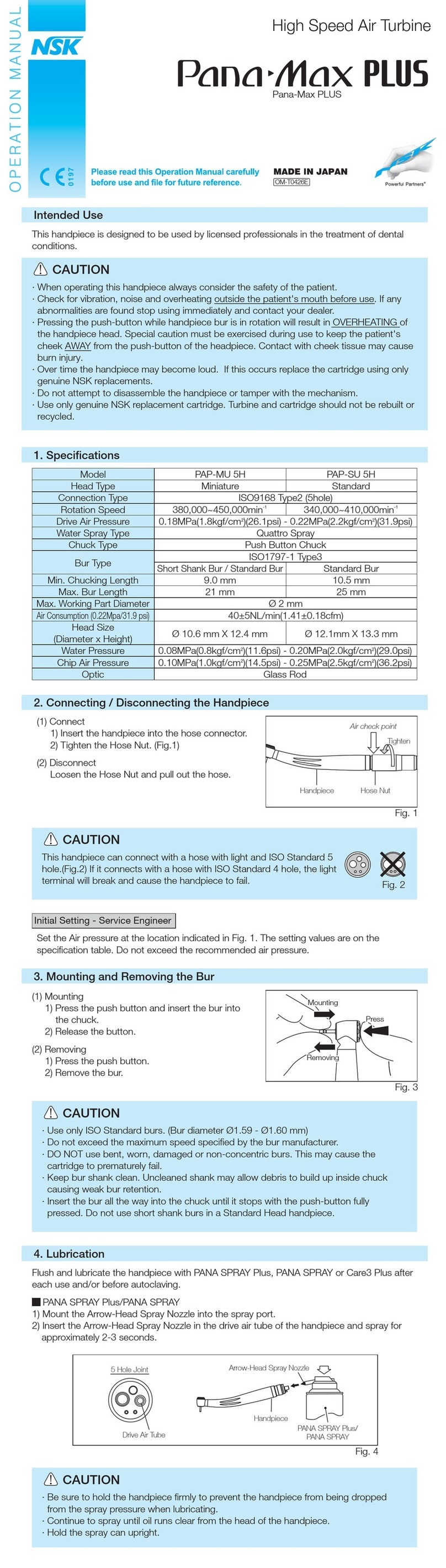

NSK Pana-Max PLUS PAP-MU 5H User manual

NSK

NSK PRESTO AQUA LUX User manual

NSK

NSK EX Series User manual

NSK

NSK Ti-Max X Series User manual

NSK

NSK Ti-Max S-Max Series User manual

NSK

NSK PANA-MAX QD User manual

NSK

NSK TI-MAX X35L User manual

NSK

NSK FXZBS M4 User manual

NSK

NSK PER-PTL-P User manual

NSK

NSK Surgic Pro User manual

Popular Dental Equipment manuals by other brands

Vatech

Vatech EzRay Air VEX-P300 user manual

KaVo

KaVo GENTLEpower LUX Contra-angle 25 LP Technician's Instructions

DENTSPLY

DENTSPLY SmartLite Focus Instructions for use

LM

LM ProPower CombiLED quick guide

Owandy Radiology

Owandy Radiology RX-AC user manual

mectron

mectron Piezosurgery Cleaning and sterilization manual