1

ENGLISH

CAUTION

• When operating the handpiece always consider the safety of the patient.

• The handpiece is designed only for dental clinical use by licensed person.

• Do not attempt to disassemble the handpiece nor tamper with the mechanism.

• Do not allow any impact on the shank. Do not drop the handpiece.

• Check the vibration, noise and overheating outside the patient's oral cavity before use. If any abnormalities are found, stop using immediately and contact your dealer.

• Should the handpiece function abnormally, cease operation immediately and return the handpiece to the dealer for repair.

• Supply PANA SPRAY Plus after each use or before autoclaving.

• Do not wipe with, or clean or immerse in, high acid water or sterilizing.

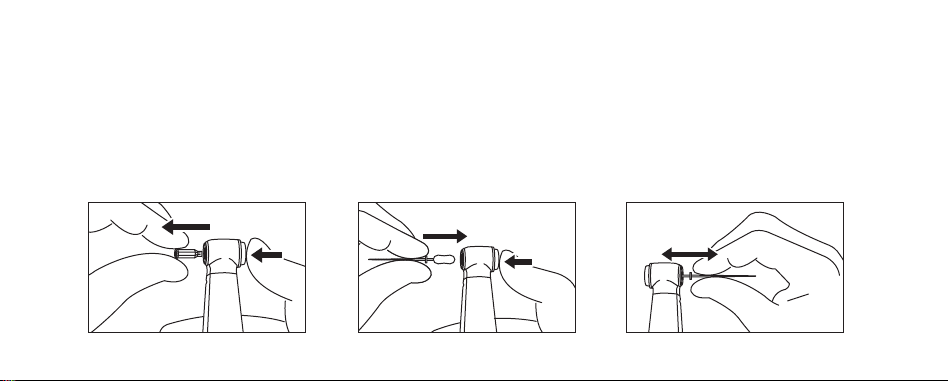

• Connecting /disconnecting handpiece or file/reamer/rubber cup have to perform when the handpiece stopped.

• Do not connect or disconnect the file or reamer until the drive motor has completely stopped.

FOR X35L,X35,X70L,X70,X75L,X75

• When you work on root canal expansion, DO NOT set the drive source (Motor) speed other than the values that written on the “ SPECIFICATION”. Follow the

maximum rotation speed that file or reamer manufacture recommends.

• Follow the package insert that file/reamer manufacture.

• Do not use bent, damaged, or sub-standard file or reamer. The shank could bent or broke even within the recommended speed.