Maintenance manual RI Series

01/09/2006 Page - 2 -

Table of Contents

1. Introduction .....................................................................................................................................4

2. General characteristics ...................................................................................................................5

2.1 Metrological characteristics: .................................................................................................5

2.2 Electrical characteristics: ......................................................................................................5

2.3 RI Series keyboard:..............................................................................................................6

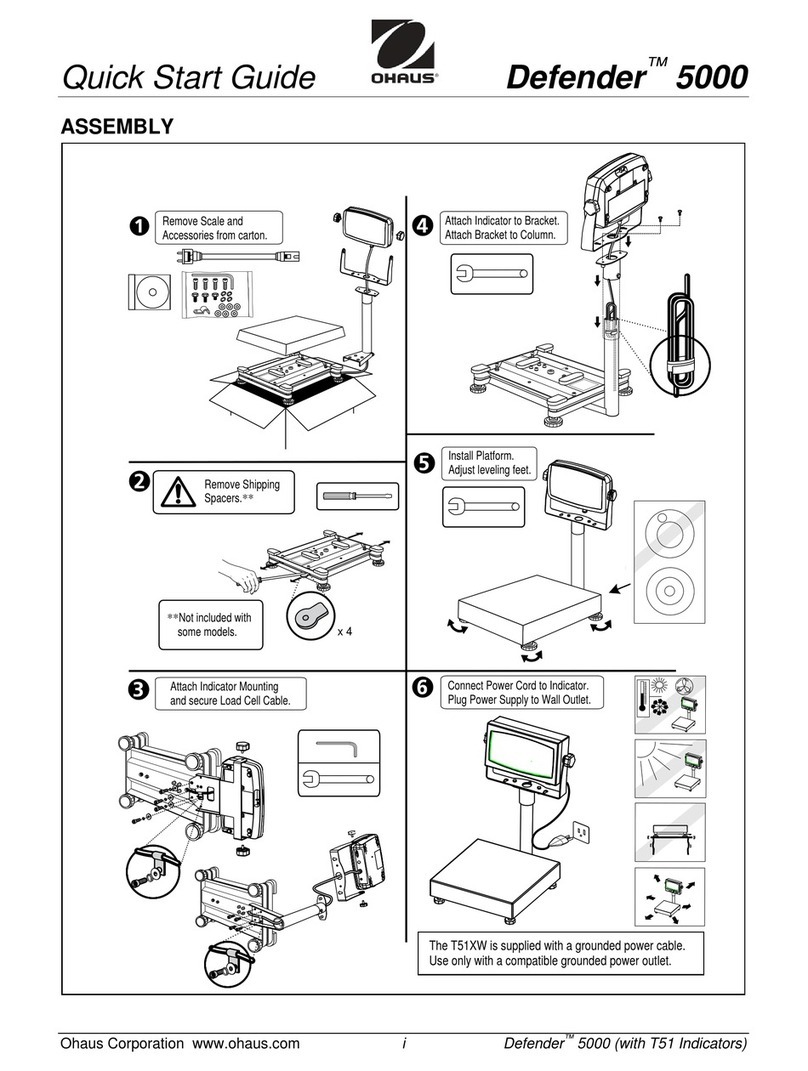

3. Installation.......................................................................................................................................8

4. RI Series exploded views..............................................................................................................10

4.1 Main shell equipped............................................................................................................10

4.2 Main shell equipped continued (29270000)........................................................................11

4.3 Final assembly with rear display.........................................................................................12

4.4 Final assembly with tower display.......................................................................................13

4.5 Fitted main shell..................................................................................................................14

4.6 Fitted display column..........................................................................................................15

4.7 Motor support equipped......................................................................................................16

4.8 Load cell support equipped.................................................................................................17

4.9 Fitted keyboard assembly...................................................................................................18

4.10 Fitted adjustable foot.......................................................................................................19

4.11 Fitted electrical socket panel...........................................................................................20

5. Seal...............................................................................................................................................21

6. Structure diagram..........................................................................................................................22

7. Diagnostic and analysis of failures................................................................................................23

7.1 Nothing happens when switching on the scales.................................................................24

7.2 Error message displaying:..................................................................................................25

7.3 Printing problems:...............................................................................................................26

8Replacements:..............................................................................................................................27

8.1 Replacing the A/D board and load cell assembly on RI Series...........................................28

8.2 Replacing the main board on RI Series..............................................................................30

8.3 Replacing the switching power supply unit on RI Series ....................................................31

8.4 Replacing the flexible keyboard on RI Series.....................................................................32

8.5 Replacing the thermal print head on RI Series...................................................................33

8.6 Replacing the fitted motor unit on RI Series.......................................................................34

8.7 Replacing the front display unit on RI Series......................................................................35

9. On site calibration procedure:.......................................................................................................36

9.1 "GEO" code modification: ...................................................................................................38

10. Technical data Test points / Settings:...........................................................................................39

10.1 Electrical characteristics:.................................................................................................39

10.2 The switching power supply unit (71207286)..................................................................42

10.3 Analogue/digital board.....................................................................................................43

10.3.1 Test points................................................................................................................43

10.3.2 Electrical diagram (29120154)..................................................................................44

10.4 RI Series CPU board (main board) .................................................................................45

10.4.1 The micro processor part..........................................................................................45

10.4.2 The printer part.........................................................................................................46

10.4.3 The display part:.......................................................................................................46

10.4.4 The communication part...........................................................................................47

10.4.5 The power supply part..............................................................................................47

10.4.6 Test points (main board 71207283)..........................................................................49

10.4.7 Diagrams..................................................................................................................50

11. Cables...........................................................................................................................................56

11.1 CPU board / Communication board (ref 71208130)........................................................56

11.2 Infra-red LED cable (Emitting cell) ref 71208141...........................................................57

11.3 Infra-red sensor cable (Receiving cell) ref 71208129.....................................................58