Table of Contents

Introduction············································· 5

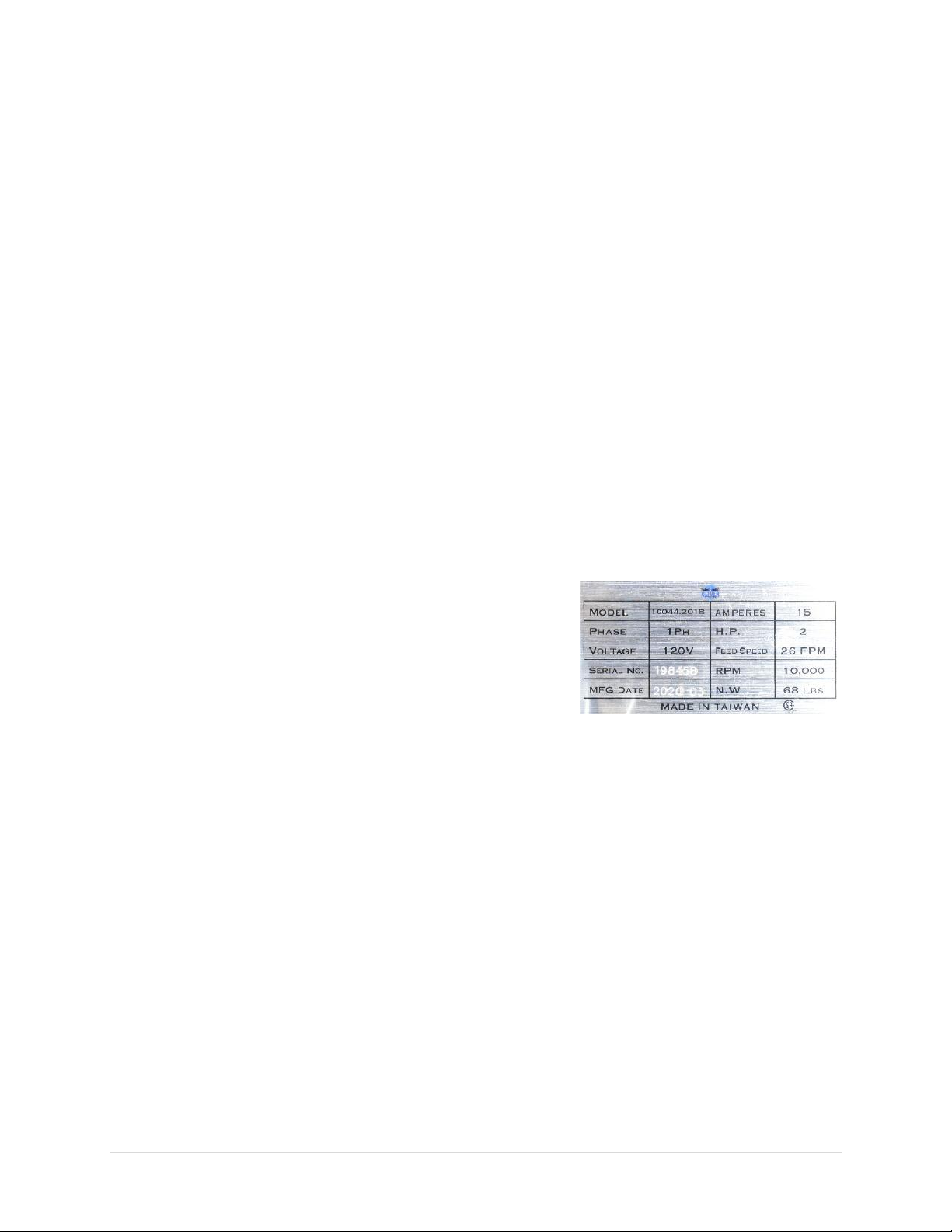

Specifications ·········································· 6

Quick View·················································6

Product Dimensions····································6

Shipment Info·············································6

Electricals···················································6

Motor ························································7

Planer Capacity and Performance ···············7

Cutterhead and Carriage·····························7

Measurements ···········································7

Table··························································8

Safety·························································8

Others························································8

Identification ··········································· 9

Safety·····················································10

General Safety Guidelines·························10

Safety Guidelines Specific to Planer···········11

Electricals ···············································13

Minimum Circuit Size Required for Model

10044 Planer············································13

Grounding ················································13

Indoor Use Only ·······································13

Electrical Wiring ·······································13

Setup······················································15

Shop Preparation······································15

Space Requirement ·········································15

Electricals ························································15

Lighting····························································15

Safety Labels ···················································15

Dust Collection ················································15

Receiving··················································16

Unboxing ·························································17

Inventory·························································17

Waxing·····················································18

Assembly ·················································18

Dust Hood Installation·····································19

Cutterhead Elevation Crank Installation ·········19

DRO Battery Installation··································19

Dust Collection ·········································20

Bench Mounting (Optional) ······················20

Controls and Components ······················ 21

ON / OFF Switches····································21

Overloading Protection Reset Button ········21

Cutterhead Height Adjustment ·················21

Carriage Lock············································21

Digital Readout (DRO)·······························22

DRO Calibration········································22

Thickness Gauge·······································22

Depth Stops ·············································23

Components for Planing Wood ·················23

Test Run···················································24

Operation ·············································· 25

Step 1: Preparation···································25

Step 2: Setting Depth of Cut······················26

Step 3: Select Feed Direction·····················27

Step 4: Planing Wood to Desired Thickness27

Common Cutting Problems ·······················29

Snipe································································29

Chipping ··························································29

Indentation······················································29

Fuzzy Grain ······················································29

Accessories ············································ 30

Cutter Inserts ···········································30

Motor Carbon Brush·································30

Maintenance ········································· 31

Maintenance Schedule ·····························31

Instructions for Maintenance and

Adjustments ············································32

Service Cutterhead and Rotate Cutter Inserts 32