Table of Contents Page Number

Warranty ........................................................................................................................................................ 2

Warnings .................................................................................................................................................... 3-4

Table of Contents .......................................................................................................................................... 5

Specifications ................................................................................................................................................ 5

Uncrating the Machine .................................................................................................................................. 6

Contents ........................................................................................................................................................ 6

Machine Preparation and Setup ................................................................................................................... 6

Dust Collection .............................................................................................................................................. 7

Electrical Connections ................................................................................................................................... 7

Control Switch ............................................................................................................................................... 7

Fence ............................................................................................................................................................ 8

Installation of the Fence ................................................................................................................................ 8

Fence Legend ............................................................................................................................................... 8

Adjustment of the 90 Degree Stop ................................................................................................................ 8

Fence Operation ........................................................................................................................................... 8

Knives ........................................................................................................................................................... 9

Knife Removal ............................................................................................................................................... 9

Knife Setting ................................................................................................................................................ 10

Adjusting the Outfeed Table........................................................................................................................ 10

Spiral Head Option .................................................................................................................................... 11

Helical Head Option .................................................................................................................................. 12

Operation ................................................................................................................................................... 13

Hand Safety and Placement ....................................................................................................................... 13

Jointing ........................................................................................................................................................ 13

Direction of the grain ................................................................................................................................... 13

Edging ......................................................................................................................................................... 13

Facing .......................................................................................................................................................... 14

Beveling....................................................................................................................................................... 14

Rabbeting .................................................................................................................................................... 14

Adjusting the Infeed Table Height ............................................................................................................... 15

Maintenance .............................................................................................................................................. 16

V-Belts ......................................................................................................................................................... 16

Lubrication ................................................................................................................................................... 16

Knives .......................................................................................................................................................... 16

Table Leveling ............................................................................................................................................. 16

Troubleshooting ........................................................................................................................................ 17

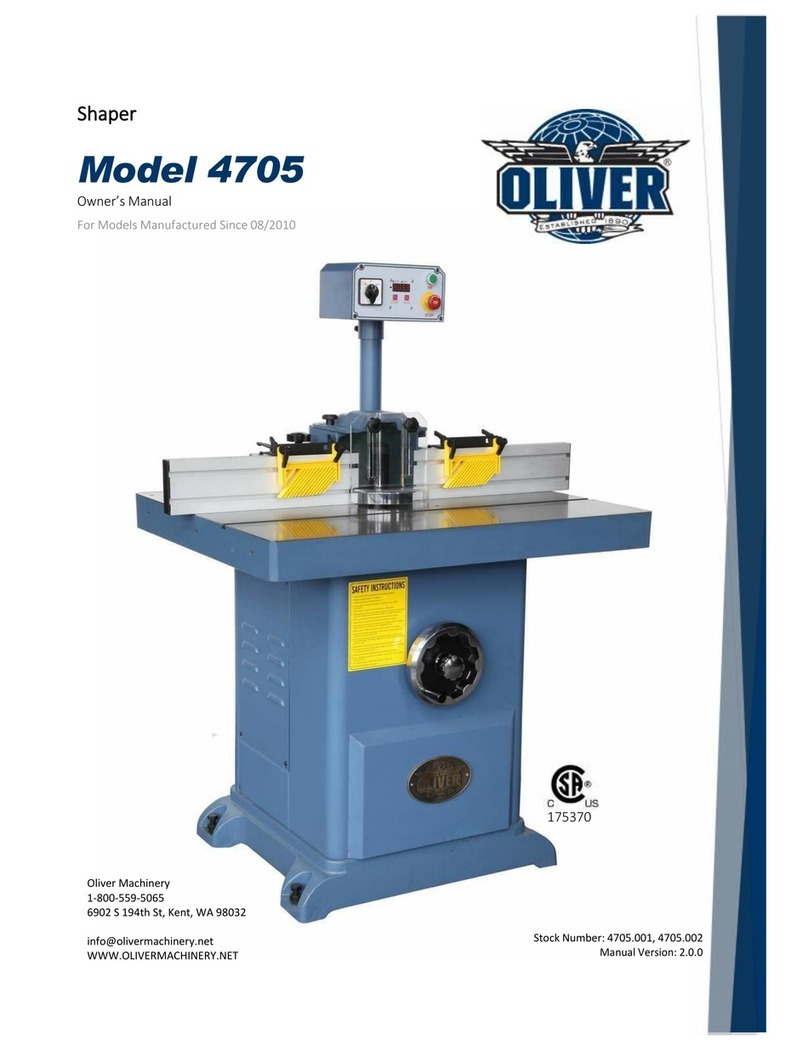

Specifications

Model No. ................................................................................................................................................ 4240

Stock No (3HP, 1PH, 220 Volt) ........................................................................................................ 4240.001

Stock No.(5HP, 3PH, 220/440 Volt, pre-wired 220 Volt) ................................................................. 4240.004

Stock No.(3HP, 1PH, 220 volt, spiral head) .................................................................................... 4240.101

Stock No (5HP, 3PH, 220/440 volt, pre-wired 220 Volt, spiral head) .............................................. 4240.104

Infeed Table Travel (in.) ............................................................................................................................. 5/8

Cutterhead speed (RPM) ........................................................................................................................ 5000

Number of Knives (Straight) .......................................................................................................................... 4

Number of Knives (Spiral) ............................................................................................................................. 3

Rabbeting Capacity (in.) ............................................................................................................................. 5/8

Dust Port Diameter (in.) ................................................................................................................................ 6

Table Dimensions (L x W/in.) .............................................................................................................. 84 x 11

Table Height (In.) .................................................................................................................................. 30-1/2

Fence Dimensions (L x H/in.) .......................................................................................................... 52 x 4-7/8

Fence Tilts (deg.) ................................................................................................................................. 90 - 45

Positive Stops (deg.) ....................................................................................................................... 90 and 45

Shipping Dimension (L x W x H/in.) ............................................................................................ 91 x 31 x 38

Overall Dimensions ..................................................................................................................... 84 x 30 x 37

Gross Weight (lbs.) ................................................................................................................................... 900

CFM ............................................................................................................ 885CFM at 4500FPM air velocity