Table of Contents

Introduction············································· 5

Specifications ·········································· 6

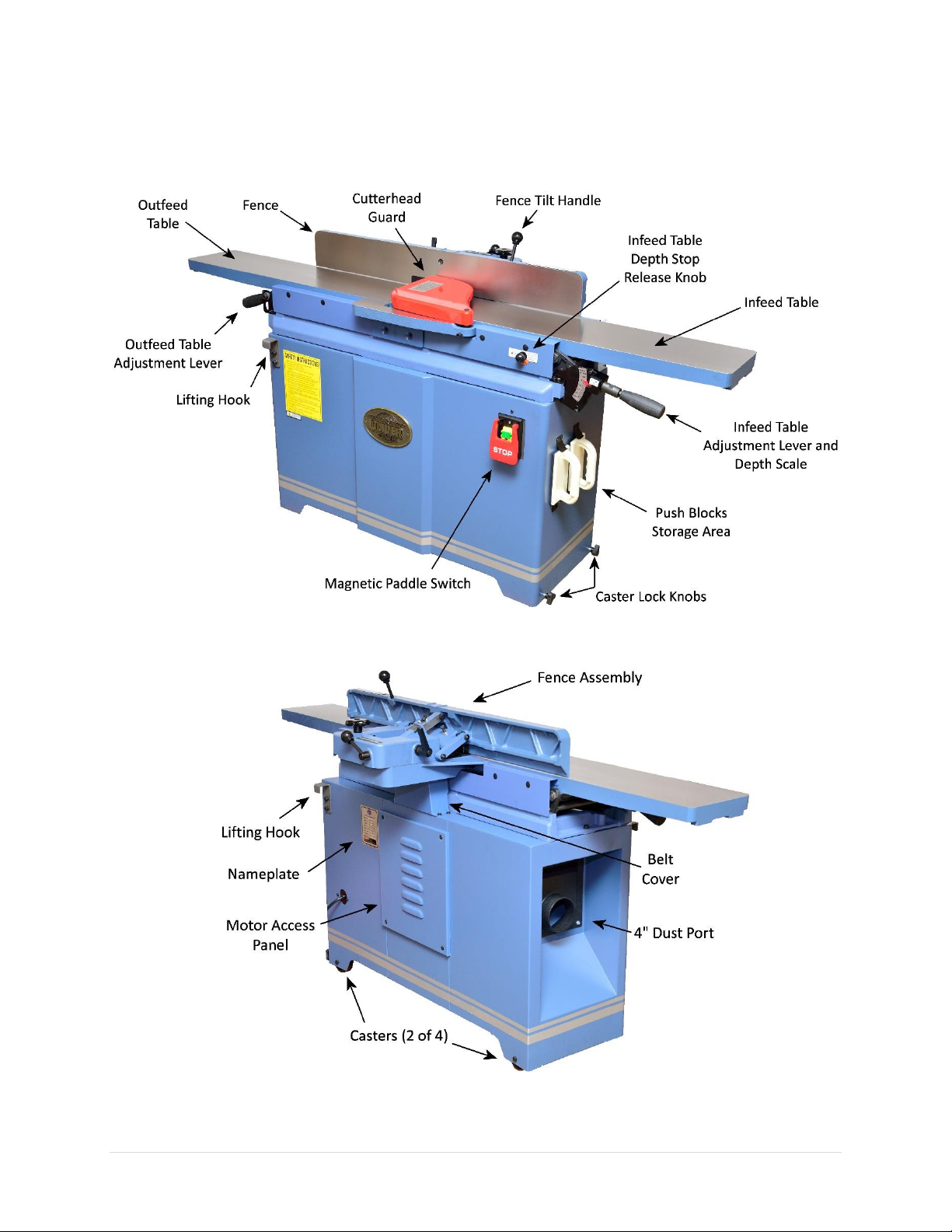

Identification ··········································· 9

Safety·····················································11

General Safety Guidelines·························11

Safety Guidelines Specific to Jointer··········12

Electricals ···············································14

Minimum Circuit Size Required for Model

4235 Jointer ·············································14

Grounding················································14

Electrical Wiring ·······································14

Setup······················································16

Shop Preparation······································16

Space Requirement ·········································16

Load Limits ······················································16

Electricals ························································16

Lighting····························································16

Safety Labels ···················································16

Dust Collection ················································16

Receiving··················································17

Cleaning···················································19

Assembly ·················································20

Dust Collection·········································22

Controls and Components ·······················23

Powerswitch ············································23

Infeed Table Adjustment ··························23

Infeed Table Depth Stop Knob ··················23

Outfeed Table Height Adjustment·············24

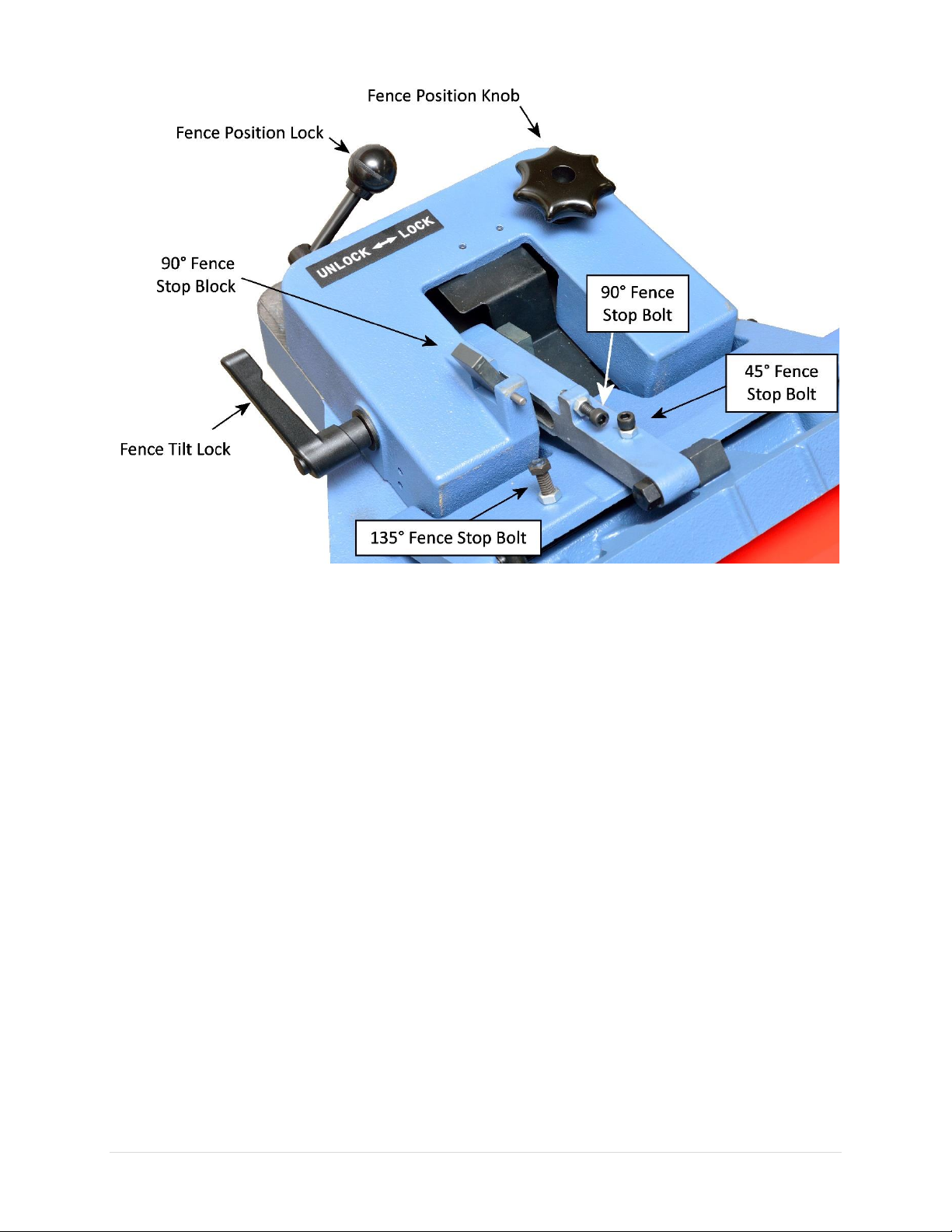

Fence ·······················································25

Test Run···················································26

Operation···············································27

Preparation··············································27

Inspect Wood Grain··································28

Squaring Stock··········································28

Surface Planing·········································29

Edge Jointing············································31

Beveling···················································31

Rabbet Cutting ·········································32

Common Cutting Problems ·······················33

Snipe································································33

Chipping ··························································33

Fuzzy Grain······················································33

Accessories ············································ 34

Maintenance ········································· 35

Maintenance Schedule ·····························35

Inspect / Adjust Jointer Tables ··················36

Inspect Outfeed Table Height ·························36

Adjust Outfeed Table Height···························36

Inspect Outfeed Table Parallelism ··················37

Inspect Infeed Table········································37

Adjust Table Parallelism/Coplanarity ··············38

Infeed Table Adjustments ·······························40

Infeed Table Depth Stop Adjustments ············41

Rotate / Replace Cutter Inserts ·················42

Adjust Fence Positive Stops ······················43

Adjust Belt Tension···································45

Align Belt Pulleys······································46

Troubleshooting····································· 47

Mechanical / Electrical Issues····················47

Operation / Quality-Related Issues ···········48

Wiring Diagram ····································· 50

Parts List················································ 51

Maintenance Record······························ 60

Notes····················································· 61

Warranty and Service····························· 62

Appendix ··············································· 63

US Standard –Metric Conversion Chart·····63