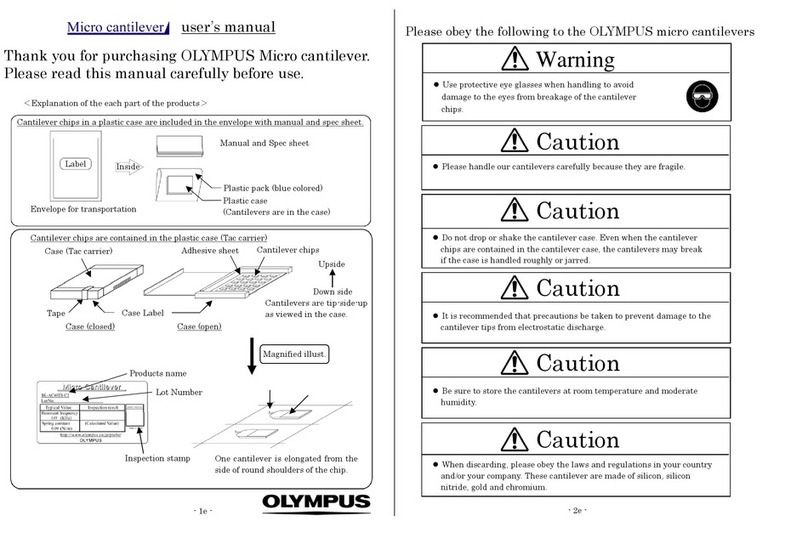

Special feature of OLYMPUS Micro cantilever (OMCL-AC160TS-W2)

- 3e -

1 Preparation

1) Please prepare the followings before using OLYMPUS cantilevers.

1. AC mode cantilever – This type of micro cantilever is for AC (dynamic) mode AFM operation.

2) To gain a better understanding of how cantilevers and chips are connected, cantilevers should

be inspected under the microscope.

High mechanical Q factor of the cantilevers allows you high sensitivity measurement to

probe your sample surface gently. This type of micro cantilever is used as a standard

cantilever for AC mode measurement.

2. Tip View – The tip is located on the very end of the cantilever.

1) Work environment

: Clean bench

(Use of an electrical charge neutralizer of ionizer is recommended.)

This feature allows you to set the tip over a point of interest on the sample, easily and 2) For hazard avoidance

3) For cantilever treatment

: Protective eye glasses

: Tweezers (sharp pointed tip), Tweezers (flat tip)

precisely, if you use an AFM combined with an optical microscope.

- 4e -

4 Tip shape of Tetrahedral tip

3. Point terminated tip – The tip radius is typically 10 nm or less.

A sharpened tetrahedral tip of single crystal silicon is employed for high-resolution

measurements. The tetrahedral shape is ideal for achieving a point terminated tip. In

addition to the geometrical dimensions of the tip, the tip is further sharpened with our

exclusive sharpening process.

4. Symmetric tip – The tetrahedral tip is thin with the macroscopic tip angle of 35 degrees

viewing from both its front and side. Tip shows good symmetry in viewing along the

cantilever axis (see Chapter 4).

Symmetric shape tip results AFM images less distortion which reduce misinterpret of

the data.

5. Reflex coating cantilever – Aluminum is coated onto the back side of the cantilevers for

optical deflection sensing.

Good S/N signal can be expected in the optical sensor circuit.

6. Compatible chip – 3.4 mm(L) x 1.6 mm(W) x 0.3 mm(t)

This type of the chip can be attached to most of AFM instruments.

Table of contents

1 Preparation

2 Open the case

3 Picking up the cantilever chip from the cantilever wafer

5 Trouble-shooting Guide

6 Information

7 Specification 1s

page

4) For inspection

2 Open the case

(Use of those made of insulator is recommended.)

(Use of anti-electrostatic discharge mat and a wrist band is

recommended.)

: Stereo microscope

1) It is recommended that the cantilever case be opened in a clean environment like a clean bench

in order to avoid the cantilever being contaminated. Handling under an ionizer is recommended.

2) Avoid wearing clothes like woolen sweaters, fleece etc that give off the static electricity when

handling the cantilever cases and chips. Use of an anti-electrostatic mat and wrist band is

preferable.

It is recommended that precautions be taken to prevent damage to the

cantilever tips from electrostatic discharge.

Caution

Avoid any contact with the cantilevers when you pull up the

cantilever tip from the case.

Caution

See the specification sheet of OLYMPUS Micro cantilevers at the last page of this manual.

4e

4e

6e

8e

Please handle our cantilevers carefully because they are fragile.

Caution

7. Easy handling – Chip are fixed through the support arms. (Bottom left illust. in the first page)

375 chips are contained in a wafer. A chip can be separated from the wafer frame by

pushing it gently in the middle with a pair of tweezers.

3) In opening the case, put the plastic case label-side down on a desk.

4e

The cantilevers are tip-side-up as viewed in the case.

4) Open the case.

3 Picking up the cantilever chip from the case

8e

1) Keep a working area on the desk. This operation is NEVER carried out in the cantilever case.