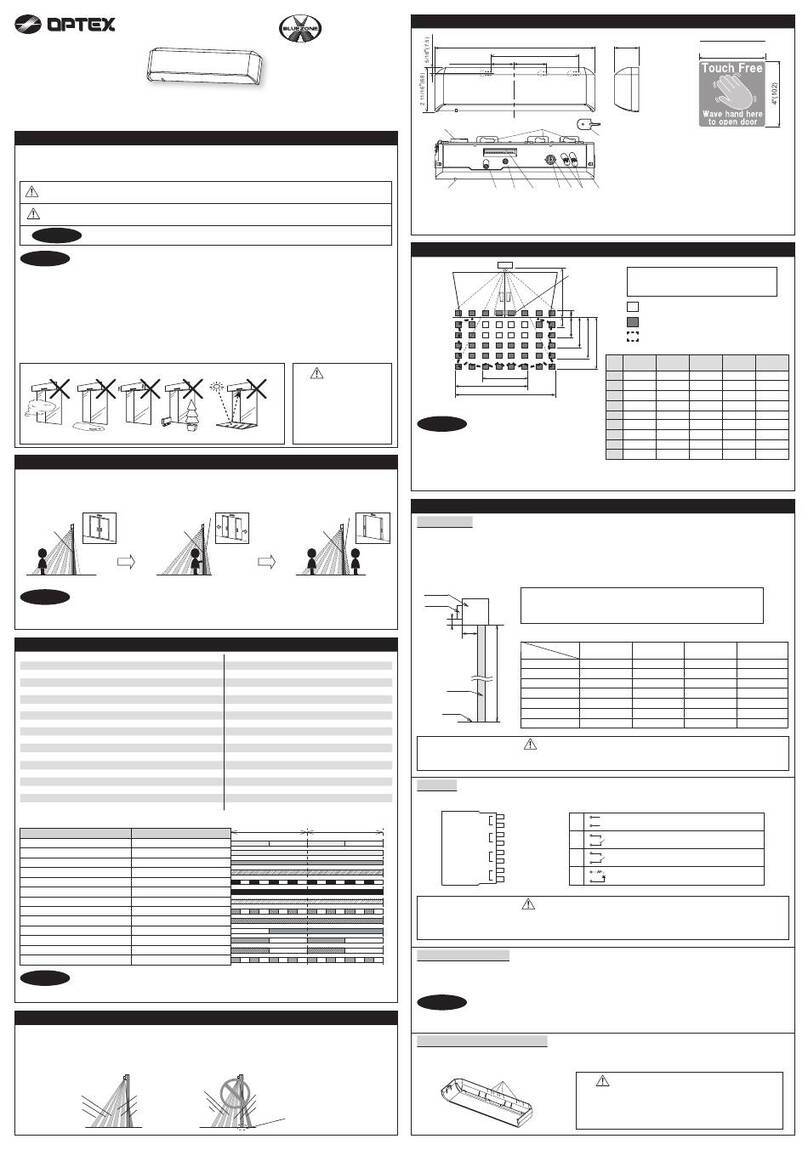

CONNECTIONS

Fig. 5 shows the terminal layout of the control unit. The three relays provide voltage-free change-over (form C)

(S.P.D.T.) contacts rated 1 Amp. at 30V MAX.

WARNING!!! DO NOT CONNECT MAINS POWER TO ANY TERMINALS.

If the control unit is located a long way from the head and heavy (1.5 or 2.5mm) cables are used, it is

recommended that the cables are terminated in a separate junction box and smaller gauge cables are taken into

the control unit terminals.

The 12volt input should preferably be from a float maintained battery/power pack capable of providing at least

100mA. with less than 0.25volt p-p ripple.

NOTE: The 12volt supply negative terminal of the control unit is connected to the case as is the negative

terminal of the head input cable so the power supply negative will be grounded. Under normal quiescent

conditions (no movement and control box lid fitted) all relays should be energised.

Cutting or disconnecting the head cable will activate (de-energise) the tamper relay.

Detection by the ‘near’ (6-100M) detector will activate the ‘near’ relay.

Detection by the ‘far’ (80-180M) detector will activate the ‘far’ relay.

Detection by both near and far detectors (mid-range) will activate the far relay only.

(The ‘far’ relay will override the ‘near’ relay).

Fig. 6 is a guide to maximum distances allowable for a selection of popular cable sizes. NOTE that the maximum

allowable resistance between the head and control unit is 20 ohms (10 ohms per conductor) and the maximum

resistance between the control unit and the D.C. power source is 12 ohms (6 ohms per conductor).

INITIAL TESTING

Double check that the power supply input is the correct polarity (negative on the right). The control unit has a

‘shunt’ diode across the input terminals and the reverse connection will blow the power supply fuse (if fitted)

or may damage the control unit if not fitted. With power applied, check that the voltage at the supply terminals

is between 11.5 and 16volts. (with a float charged battery/power pack the voltage should be around 13.5V). If

an oscilloscope is available, check that ripple is less than 0.25volt p-p. Check that the head signal cables are

the correct way round (negative on the left) and that a voltage of between 9 and 12 is present. If no voltage is

present, the head leads may be reversed. The supply LED should be lit.

Allow at least 60 seconds for the detector head to settle. The relays and associated LED indicators may switch

rapidly during this period. With no movement in the protective zones the near and far relays should be energised

and the indicators out. The tamper relay and light will be in alarm, pressing the tamper switch extension should

energise the relay and extinguish the light. If it does not, the head signal cable is open-circuit.

Where the head is located some distance away from the control unit, a quick way of checking that the system is

working is to connect a meter (set for 100 milliamps range) in series with the positive signal lead to the control

unit terminal. When the system is first energised the head currents will fluctuate between 20 and 50 milliamps

for some thirty seconds then should settle to around 7.5mA. Movement within the ‘near’ zones should cause the

current to rise to around 19mA. Movement within the ‘far’ zones should register around 31mA and movement

midway, with both detectors activated should register around 42mA.

NOTE: Waving a hand close to the front of the detector may not cause an alarm because the hand will be out

of focus. For initial system testing it is better to angle the head down and walk across the zones a few metres

away.