Table of Contents

1. About this Document ____________________________________________________________________5

1.1. Objective and Target Audience of this User Manual ________________________________________5

1.2. Symbols and Typographic Conventions __________________________________________________5

1.3. Other Applicable Documents __________________________________________________________5

2. Safety ________________________________________________________________________________6

2.1. Intended Use ______________________________________________________________________6

2.2. General Safety Instructions ___________________________________________________________6

2.3. Warnings and Safety Notices __________________________________________________________6

2.4. Organizational Measures _____________________________________________________________8

3. Product Description _____________________________________________________________________8

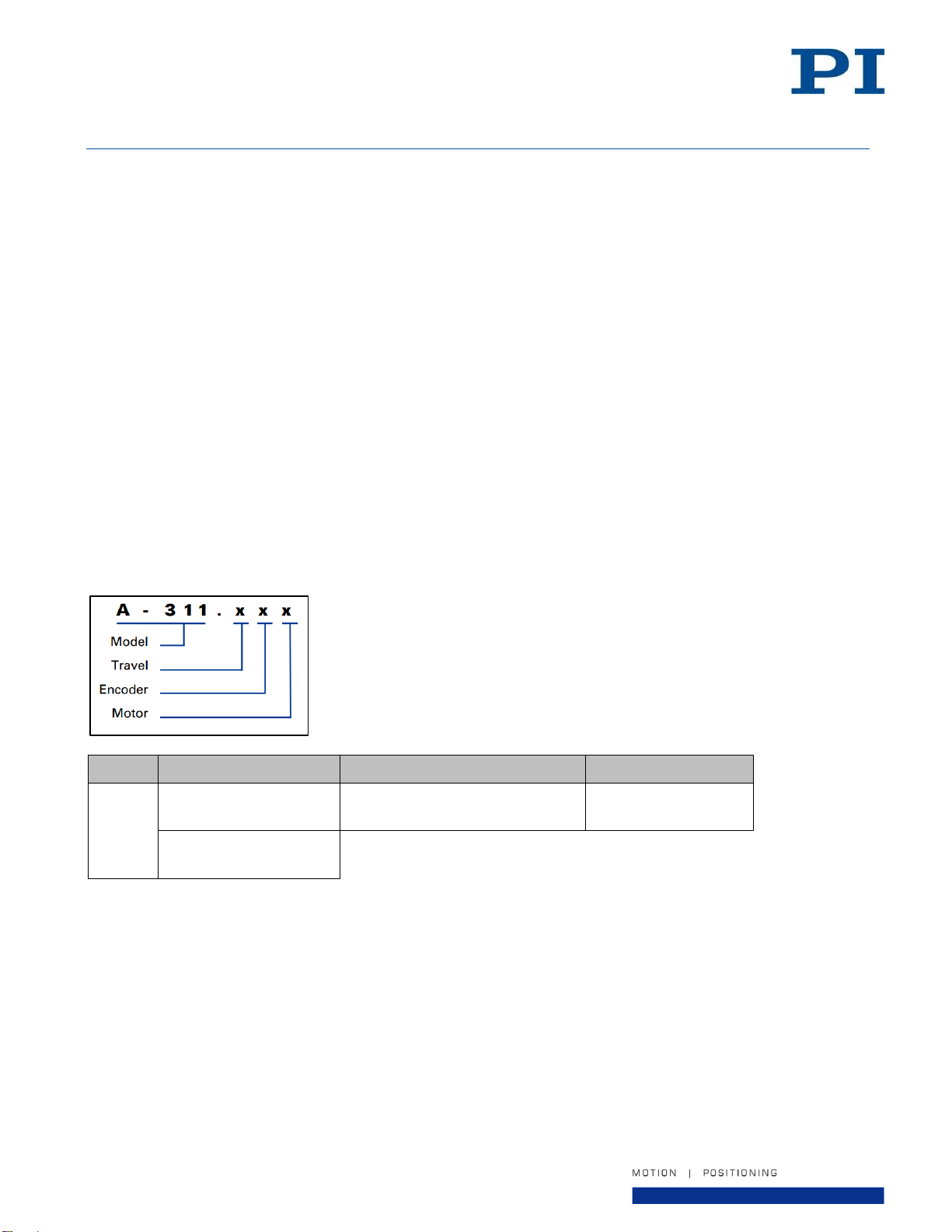

3.1. Model Overview and Part Numbering ___________________________________________________8

3.2. Product Features ___________________________________________________________________9

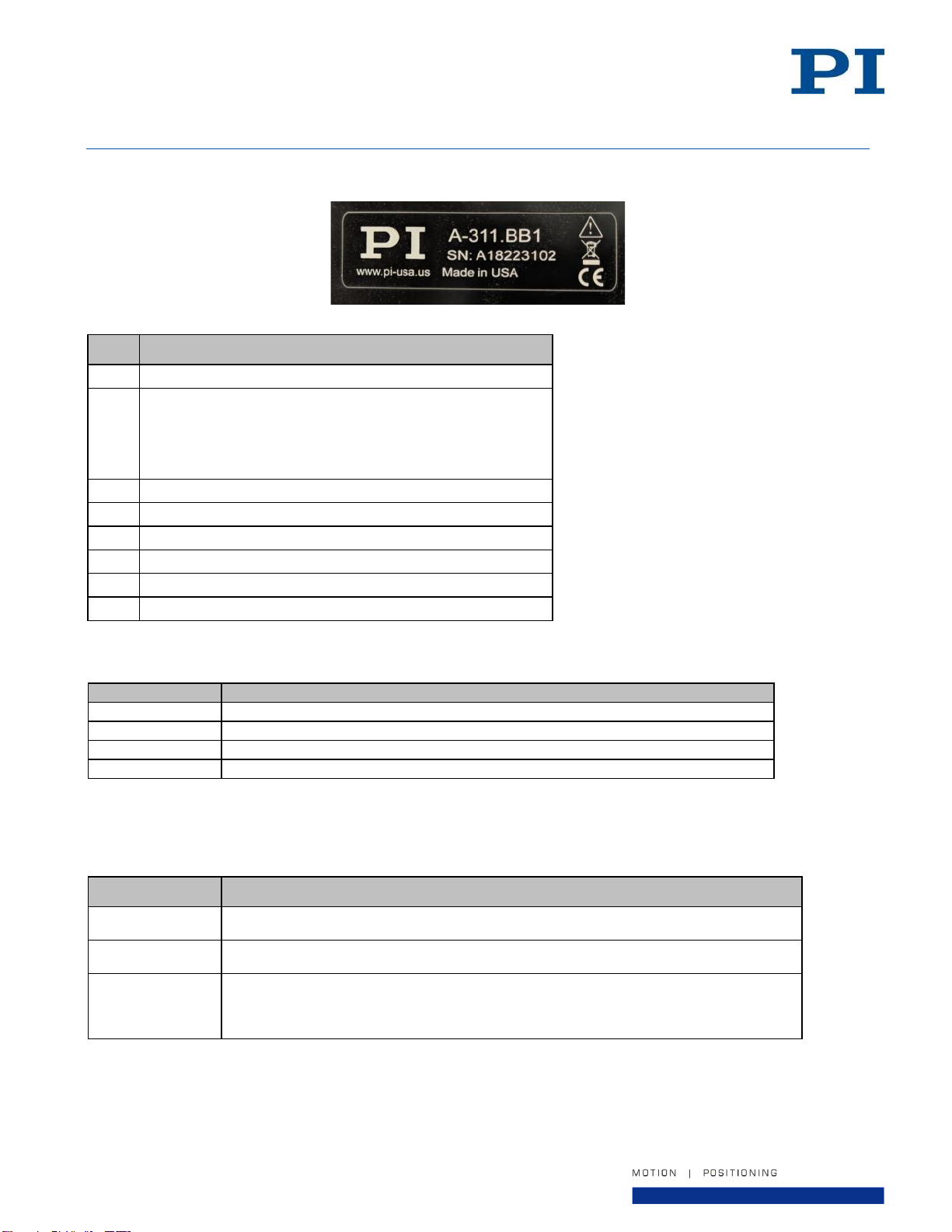

3.3. Product Labeling__________________________________________________________________ 10

3.4. Scope of Delivery _________________________________________________________________ 10

3.5. Accessories & Cables ______________________________________________________________ 10

3.6. Compatible Controllers ____________________________________________________________ 11

4. Technical Features ____________________________________________________________________ 11

4.1. Air Bearing ______________________________________________________________________ 11

4.2. Linear Motor_____________________________________________________________________ 11

4.3. Linear Encoder ___________________________________________________________________ 11

4.4. Stage Lockdown Control (Optional) ___________________________________________________ 11

5. Unpacking and Handling________________________________________________________________ 12

6. Installation __________________________________________________________________________ 13

6.1. Mounting Surface Quality and Preparation _____________________________________________ 13

6.2. Mounting Procedure ______________________________________________________________ 14

6.3. Removing the shipping lock(s) _______________________________________________________ 14

6.4. Air & Vacuum Supply ______________________________________________________________ 15

6.5. Affixing the Payload to the Stage _____________________________________________________ 15

6.6. Connecting the Stage to Protective Earth ______________________________________________ 16