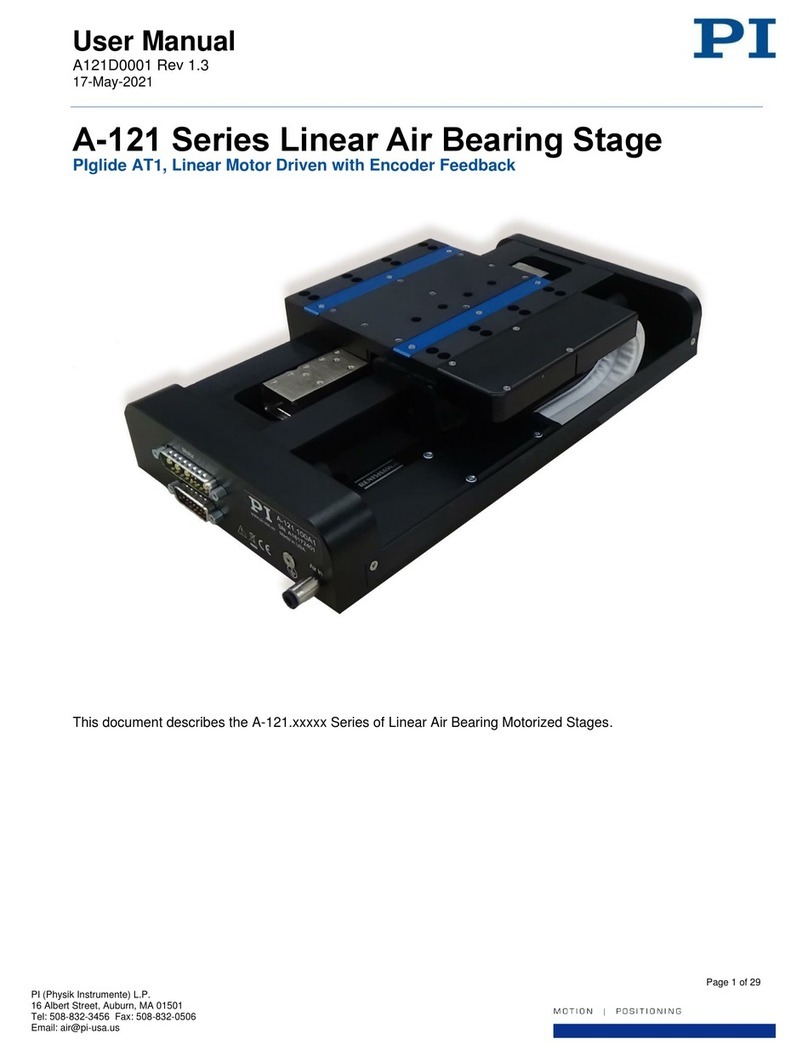

1About this Document 3

1.1 Objective and Target Audience of this User Manual............................................3

1.2 Symbols and Typographic Conventions...............................................................3

1.3 Definition...............................................................................................................4

1.4 Figures..................................................................................................................4

1.5 Other Applicable Documents................................................................................5

2Safety 6

2.1 Intended Use ........................................................................................................6

2.2 General Safety Instructions..................................................................................6

2.3 Organizational Measures......................................................................................7

3Product Description 9

3.1 Model Overview....................................................................................................9

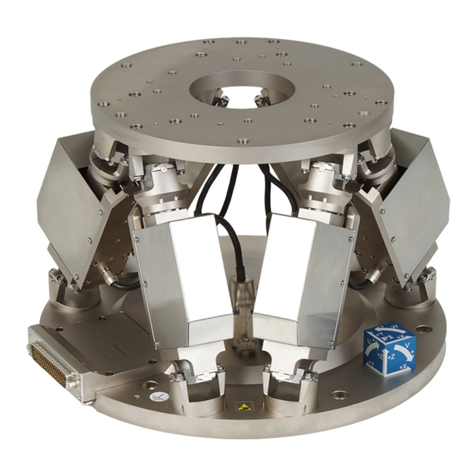

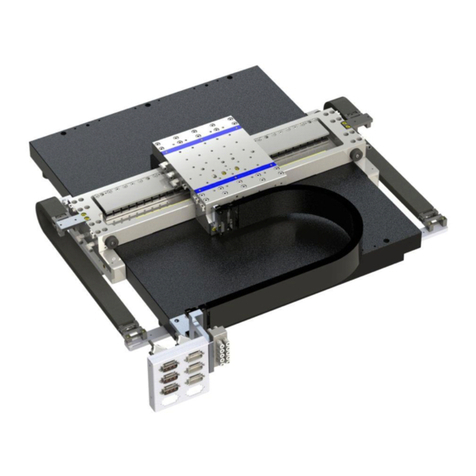

3.2 Product View.......................................................................................................11

3.3 Product Labeling.................................................................................................12

3.4 Direction of Motion..............................................................................................13

3.5 Scope of Delivery ...............................................................................................14

3.6 Technical Features.............................................................................................14

3.6.1 Encoder ............................................................................................14

3.6.2 Reference Point Switch ....................................................................14

3.6.3 Integrated PWM Amplifier.................................................................15

4Unpacking 17

5Installation 19

5.1 General Notes on Installation.............................................................................19

5.2 Optional: Modifying the Connection Orientation on the M-06x...........................20

5.3 Optional: Aligning the Hole Pattern of the Platform............................................22

5.4 Mounting the M-06x on a Surface ......................................................................24

5.5 Affixing the Load to the M-06x............................................................................26

5.6 Connecting the Motor Cable to the M-06x..........................................................27

5.7 Connecting the Power Supply to the M-06x.......................................................28

6Start-Up 29

6.1 General Notes on Start-Up.................................................................................29

6.2 Starting Up the Rotation Stage...........................................................................31

Contents