1About this Document 1

1.1 Objective and Target Audience of this User Manual.................................................. 1

1.2 Symbols and Typographic Conventions...................................................................... 1

1.3 Definition of Terms..................................................................................................... 2

1.4 Figures ........................................................................................................................ 2

1.5 Other Applicable Documents ..................................................................................... 3

1.6 Downloading Manuals................................................................................................ 3

2Safety 5

2.1 Intended Use .............................................................................................................. 5

2.2 General Safety Instructions ........................................................................................ 5

2.3 Organizational Measures............................................................................................ 6

3Product Description 7

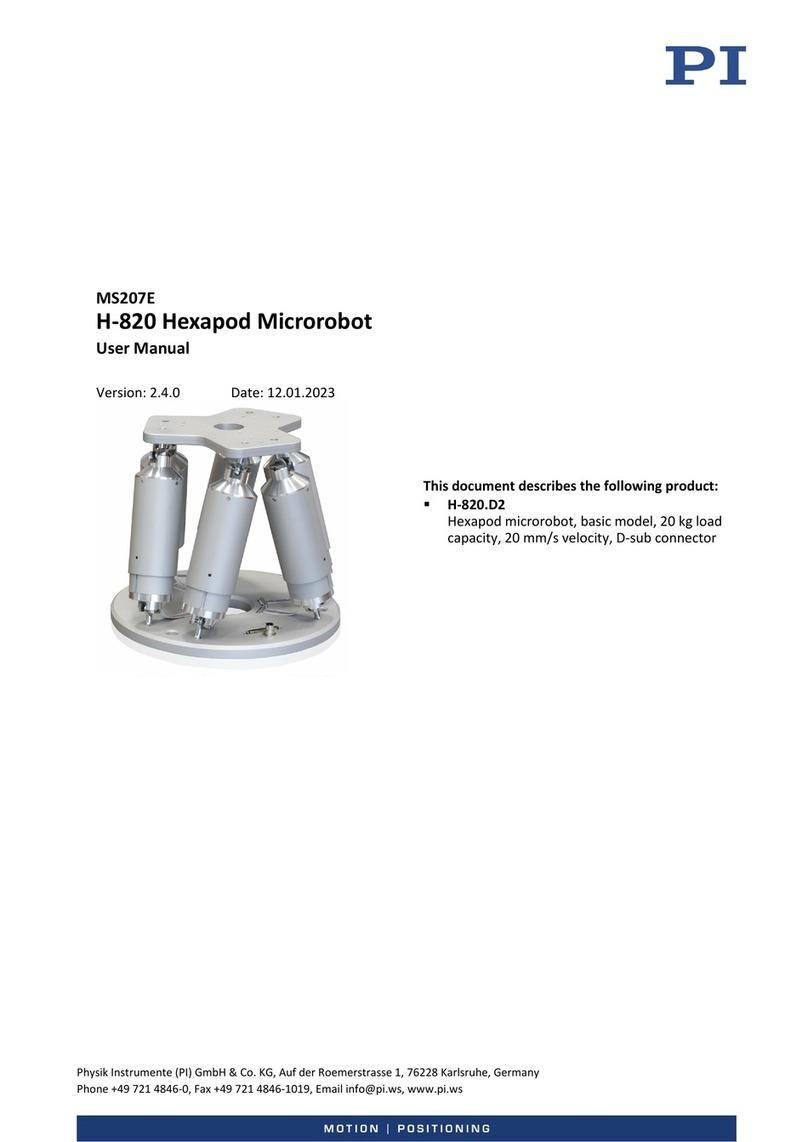

3.1 Model Overview ......................................................................................................... 7

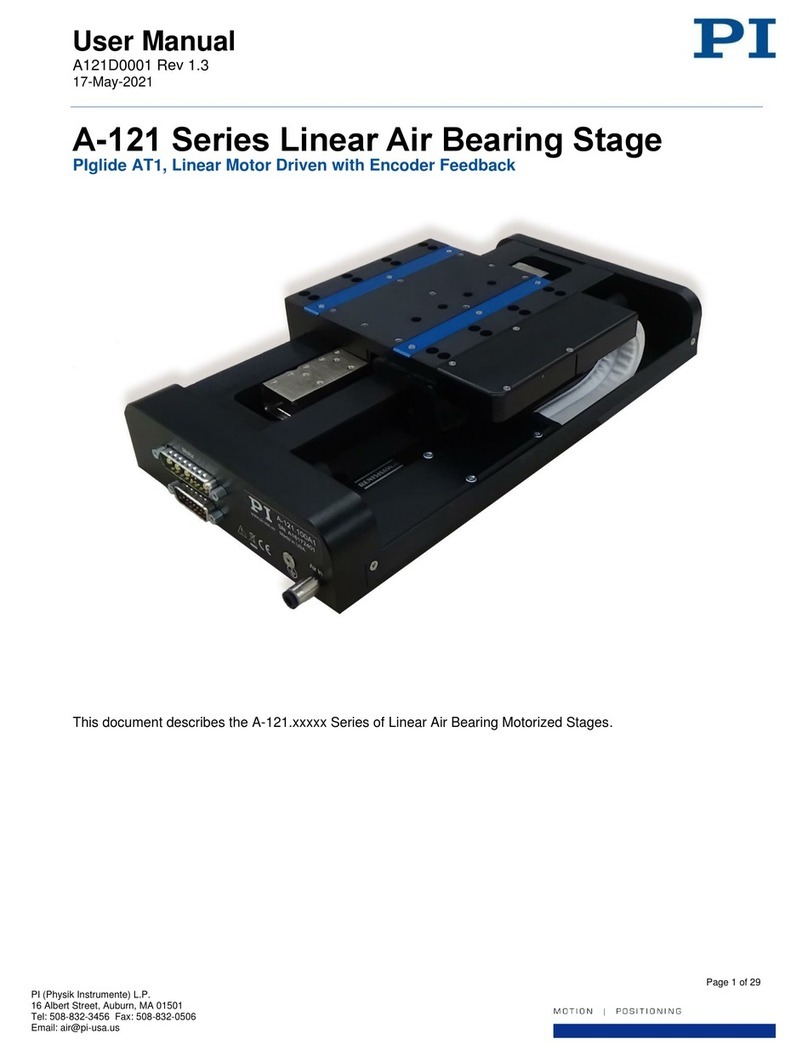

3.2 Product View .............................................................................................................. 8

3.3 Product Labeling......................................................................................................... 8

3.4 Scope of Delivery...................................................................................................... 10

3.5 Suitable Controllers .................................................................................................. 10

3.6 Accessories ............................................................................................................... 10

3.7 Technical Features.................................................................................................... 11

3.7.1 Rotary Encoder ............................................................................................ 11

3.7.2 Reference Switch......................................................................................... 11

3.7.3 ID Chip.......................................................................................................... 11

4Unpacking 13

5Installation 15

5.1 General Notes on Installing ...................................................................................... 15

5.2 Connecting the U-651 to the Protective Earth Conductor....................................... 17

5.3 Mounting the U-651 onto a Surface......................................................................... 18

5.4 Fixing the Load to the U-651 .................................................................................... 20

5.5 Connecting the Vacuum Version to the Controller.................................................. 22

6Starting and Operating 23

6.1 General Notes on Starting........................................................................................ 23

6.2 Starting and Operating the U-651 ............................................................................ 26

6.3 Adjusting Parameter Values when Using Extension Cables ..................................... 27

Contents