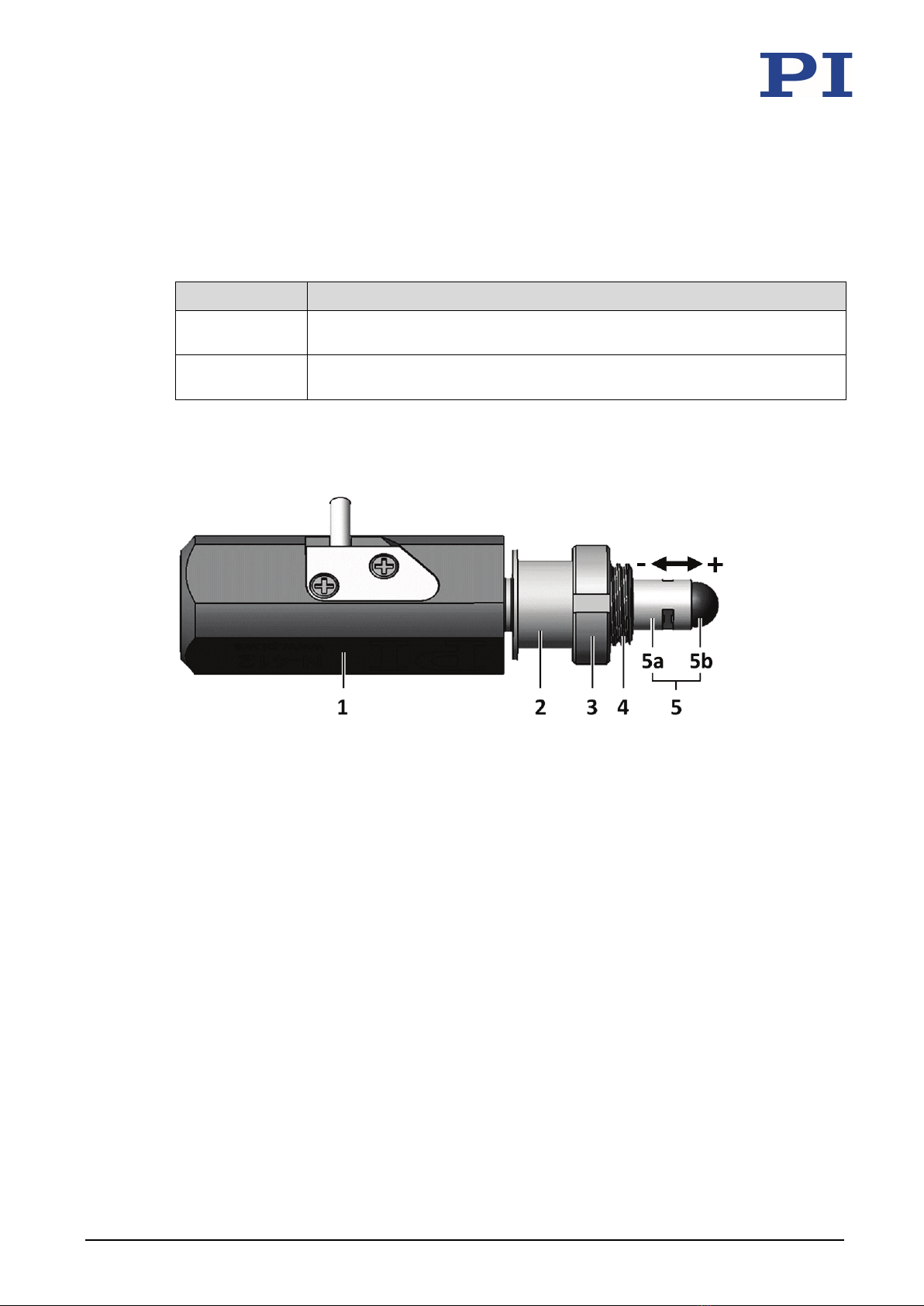

N-412 Piezo Motor Rod Drive N412T0001 Version: 1.2.1 7

Downloading manuals

If you have requested access data for protected contents via a registration page (see above):

Click the links in the browser window to change to the content for your product and log

in using the access data that you received.

General procedure:

1. Open the website www.pi.ws.

2. If access to the manuals is protected by a password:

a) Click Login.

b) Log in with the user name and password.

3. Click Search.

4. Enter the product number up to the period (e.g., N-412) or the product family (e.g., rod

drive) into the search field.

5. Click Start search or press the Enter key.

6. Open the corresponding product detail page in the list of search results:

a) If necessary: Scroll down the list.

b) If necessary: Click Load more results at the bottom of the list.

c) Click the corresponding product in the list.

7. Click the Downloads tab.

The manuals are shown under Documentation.

8. Click the desired manual and save it to the hard disk of your PC or to a data storage

medium.

2Safety

2.1 Intended Use

The N-412 is a laboratory device as defined by DIN EN 61010-1. It is intended to be used in

interior spaces and in an environment which is free of dirt, oil, and lubricants.

The N-412 is a linear drive for integration in motion systems that are used for positioning,

adjustment and motion of an object (load) in one axis. For integration, the mechanics in which

the N-412 is to be installed must have suitable guides. The N-412 can be mounted horizontally

or vertically.

The N-412 linear drive uses the principle of inertia (stick-slip effect). The feed of the moving

part is produced by alternating static and sliding friction between the moving part and a

cyclically activated piezo actuator. The object to be moved (load) is coupled to the moving part

of the N-412.

When at rest, the drive is self-locking, requires no current and generates no heat. It holds the

position with maximum force.

The N-412 is not intended for continuous operation. For further information on the operating

conditions of the N-412, see “Technical Data” (p. 20).