Handling + Storing of Panels

Handling + Storing of Panels

Handling

• When a3 CeramicSteel panels are shipped, they

are protected by craft paper or a self-adhesive

transparent polyethylene ilm. Keep panels in the

original package until installation.

• Handle with care to prevent damage.

• Never slide panels o the stack during handling.

Panels should always be lifted and moved in a

vertical position.

• Never place an a3panel in a vertical position on

the loor. This is to prevent damage to the edges.

• Prevent dirt from settling on and between panels

to avoid surface damage, scratches or defects.

• Follow all safety instructions regarding personal

protection when processing the panels.

• Protect panel surface against sawdust and

sparks (metal particles).

• a3CeramicSteel will chip when cut or drilled with

power tools. Hand-cutting can cause chipping

up to approx. 2 mm from the edge. When

chipping is in excess of 2 mm, please check the

state of cutting tools and check that the panel is

adequately supported and clamped to prevent it

from vibrating.

• All cut or drilled sections should be protected

against humidity with PVC tape and/or by

covering/sealing proiles or sealing washers.

• For detailed processing instructions, please refer

to the a3processing instructions.

Storing

• Keep panels dry and free of debris.

• Store panels inside temps 5090 °F (1032 °C).

• Any panels stored outside should be protected

from inclement weather conditions.

• Place panels on hard, lat surfaces that are not

subject to standing water.

• a3CeramicSteel panels should be stacked no

more than three high.

• Panels should never be stored vertically or in

such a way that the corners are vulnerable to

damage.

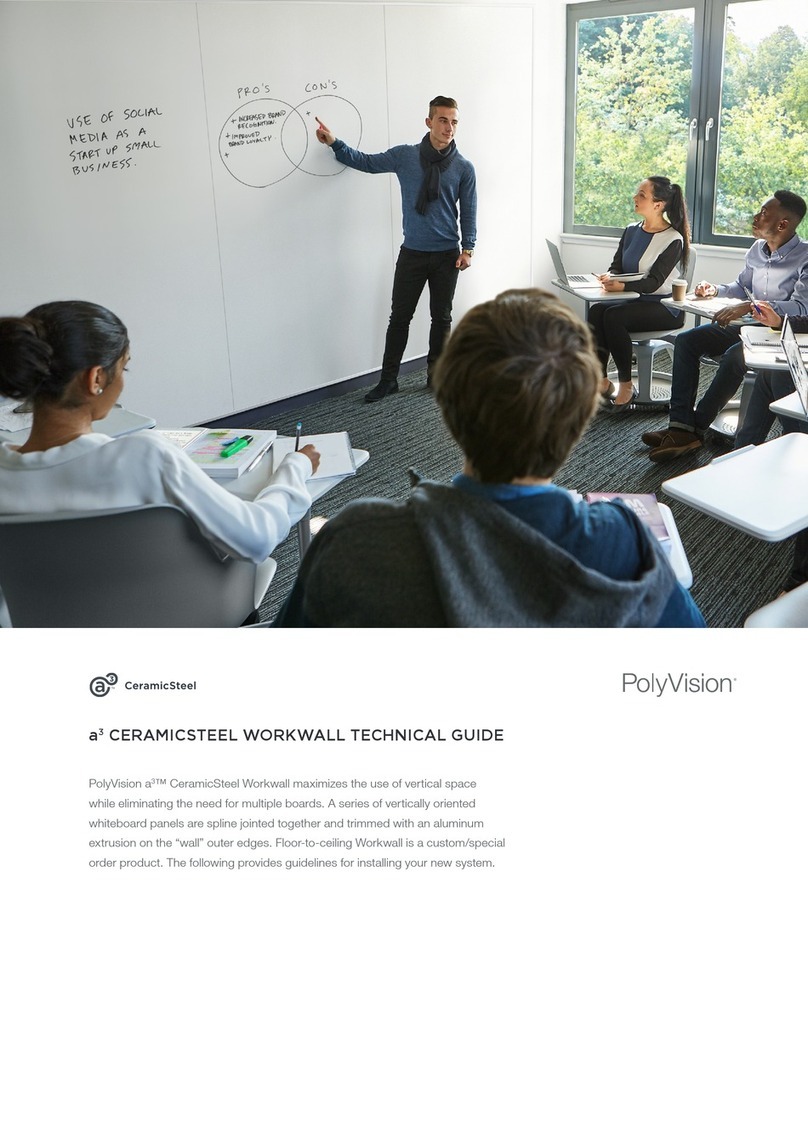

If you have a problem, question, or a request, call

your local fabricator, your regional sales manager

or PolyVision Customer Service. PolyVision’s global

customer service team can be contacted on

polyvision.com.

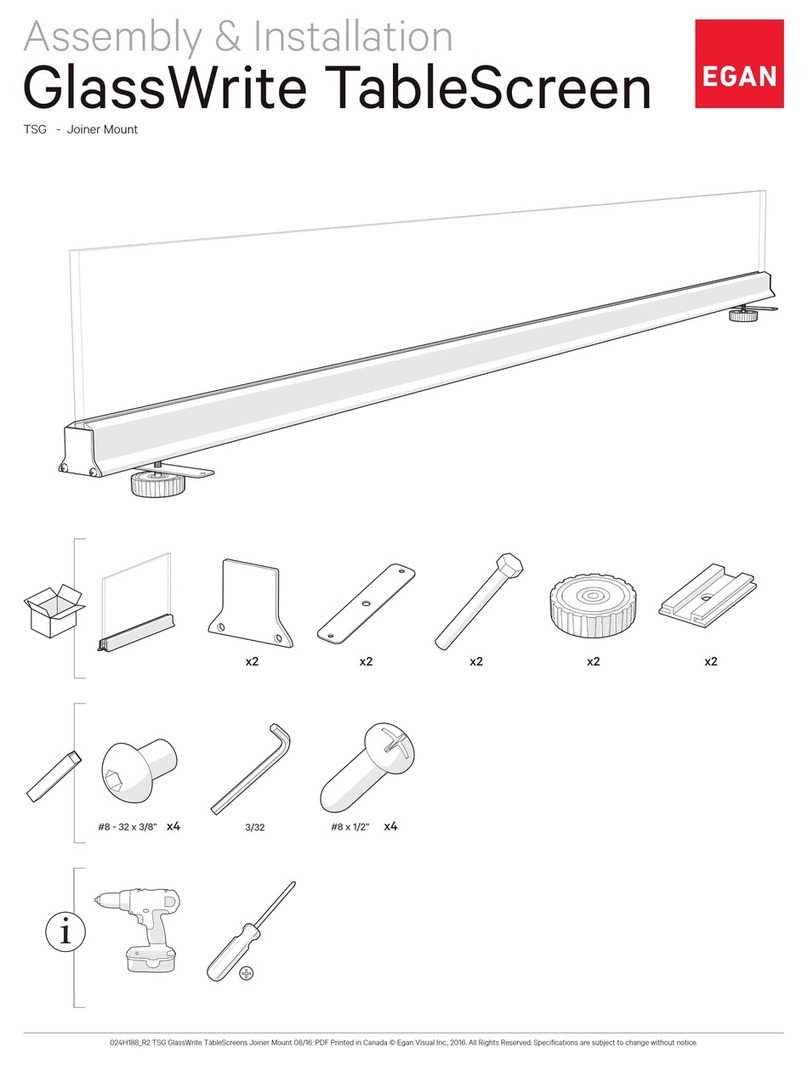

Required Materials + Equipment

Required Materials + Equipment

Electrical Equipment

1. Drill

2. Miter saw

3. Grinder

4. Jigsaw

5. Industrial vacuum cleaner

Hardware Equipment

1. Level (laser level recommended)

2. Aluminum straight guide

3. Chalk line

4. Anchors adapted to wall

• For gypsum walls, use #8 plastic wall anchor with #8 x 11/4” (4 mm x 35 mm) self drilling screws.

• For stone walls, anchors and screws must be provided by installer per conditions

• Recommended anchor spacing is 406 mm (16”) to 610 (24”) on center

5. Shims 1 mm - 2 mm - 3 mm (1/32” - 1/16” - 1/8”)

6. Soft wood block ± 50 mm x 25 mm x 300 mm (2” x 1” x 12”) length or rubber mallet to knock in the coverstrip

7. Glass suction cup lifters (2)

Included Hardware

1. Anchors

2. Screws

Doc # 81816 | Rev C | Page 4of 56 Doc # 81816 | Rev C | Page 5of 56