Optigo OP5U user manual Chapter 3 Technical data 8

Chapter 3 Technical data

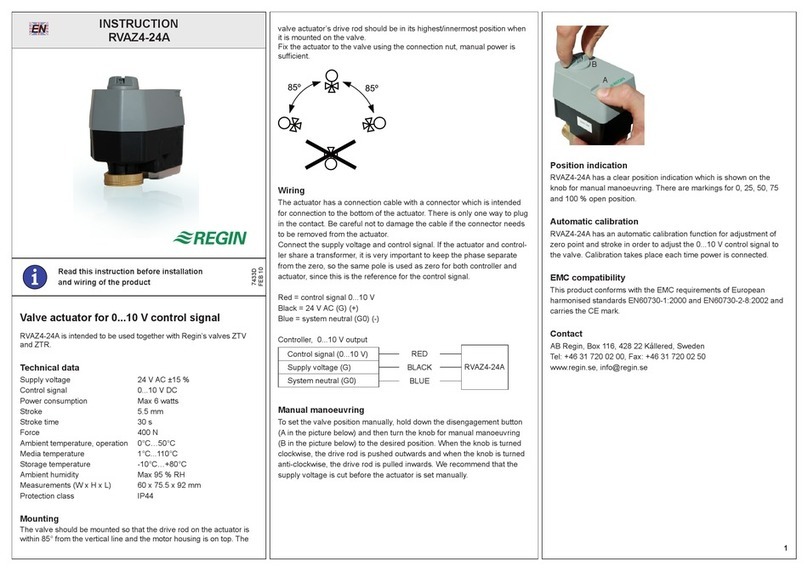

Supply voltage ................................................................................ 24 V AC ±15%, 50...60 Hz

Power consumption ...........................................................................................................3 VA

Ambient temperature .................................................................................................... 0...50°C

Ambient humidity.................................................................................................Max 90% RH

Storage temperature................................................................................................... -20...70°C

Terminals......................... Disconnectable, so-called lift type for cable cross-section 2.5 mm2

Protection class................................................................................................................... IP20

Material casing ............................................................................................. Polycarbonate, PC

Colour

Cover ................................................................................................................................ Silver

Bottom part.................................................................................................................Dark gray

Weight ....................................................................................................... 215 g incl. terminals

Dimensions.........................................................122 x 120 x 64 mm (WxHxD incl. terminals)

LVD, Low Voltage Directive

This product conforms with the requirements of European LVD standard IEC EN 61010-1.

EMC emissions an immunity standard

This product conforms with the requirements of European EMC standards CENELEC EN

61000-6-1 and EN 61000-6-3 and carries the CE mark

Inputs

AI........................................................................................................... Resolution: 10 bit A/D

AI1..................... PT1000-sensor, range -20…+140°C, divided into three measuring ranges,

accuracy +/- 0.5°C

SPI ........................................................................... PT1000 setpoint device, range 0…40°C

AGND ...........................................Reference for AI and for UI when used as an analogue input

UI

AI................................................................. 0...10 V DC, accuracy +/- 0.15 % of full output

or DI ........................................................................................ Closing potential-free contact

UI+ .....................................................................Reference for UI when used as a digital input

DI................................................................................................ Closing potential-free contact

DI+ ..................................................................................................................Reference for DI

Output

AO1 .................................................................. 0…10 V DC; 8 bit D/A short-circuit protected

AO2 .................................................................. 0…10 V DC; 8 bit D/A short-circuit protected

Agnd ...................................................................................Signal neutral for analogue outputs

Other data

Display ................................................................ Numeric / graphic. Background illumination