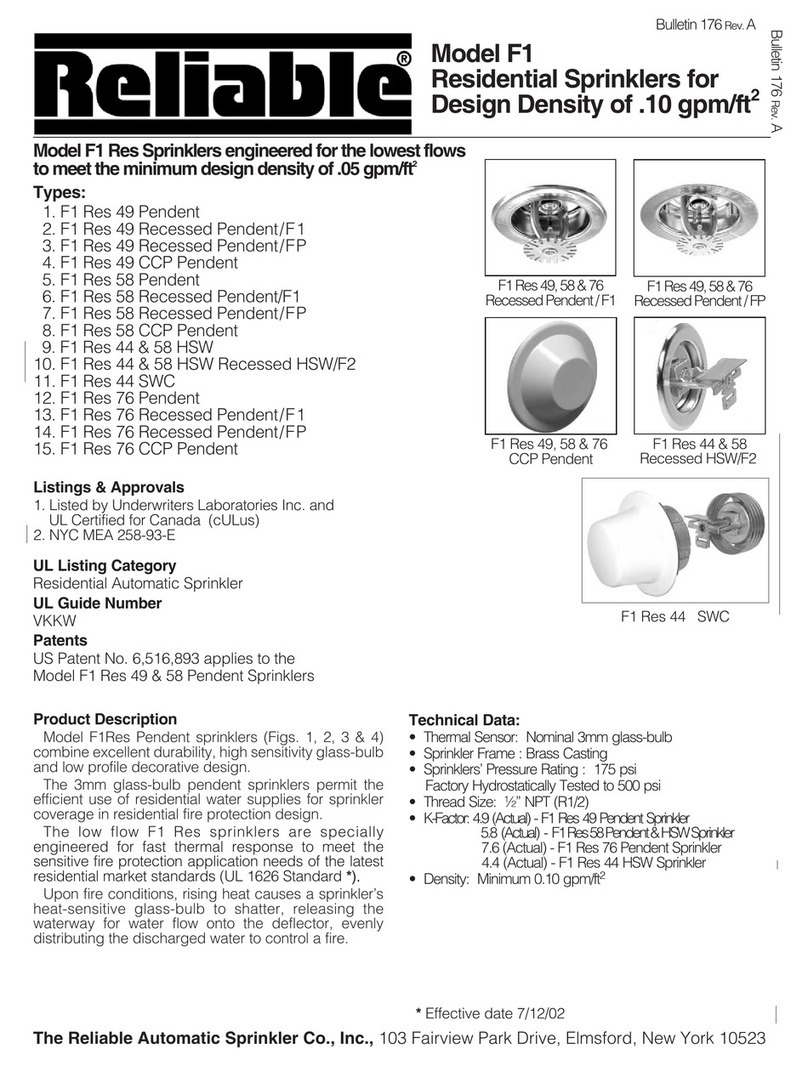

Reliable JL-17 User guide

Other Reliable Irrigation System manuals

Reliable

Reliable F156 Series Manual

Reliable

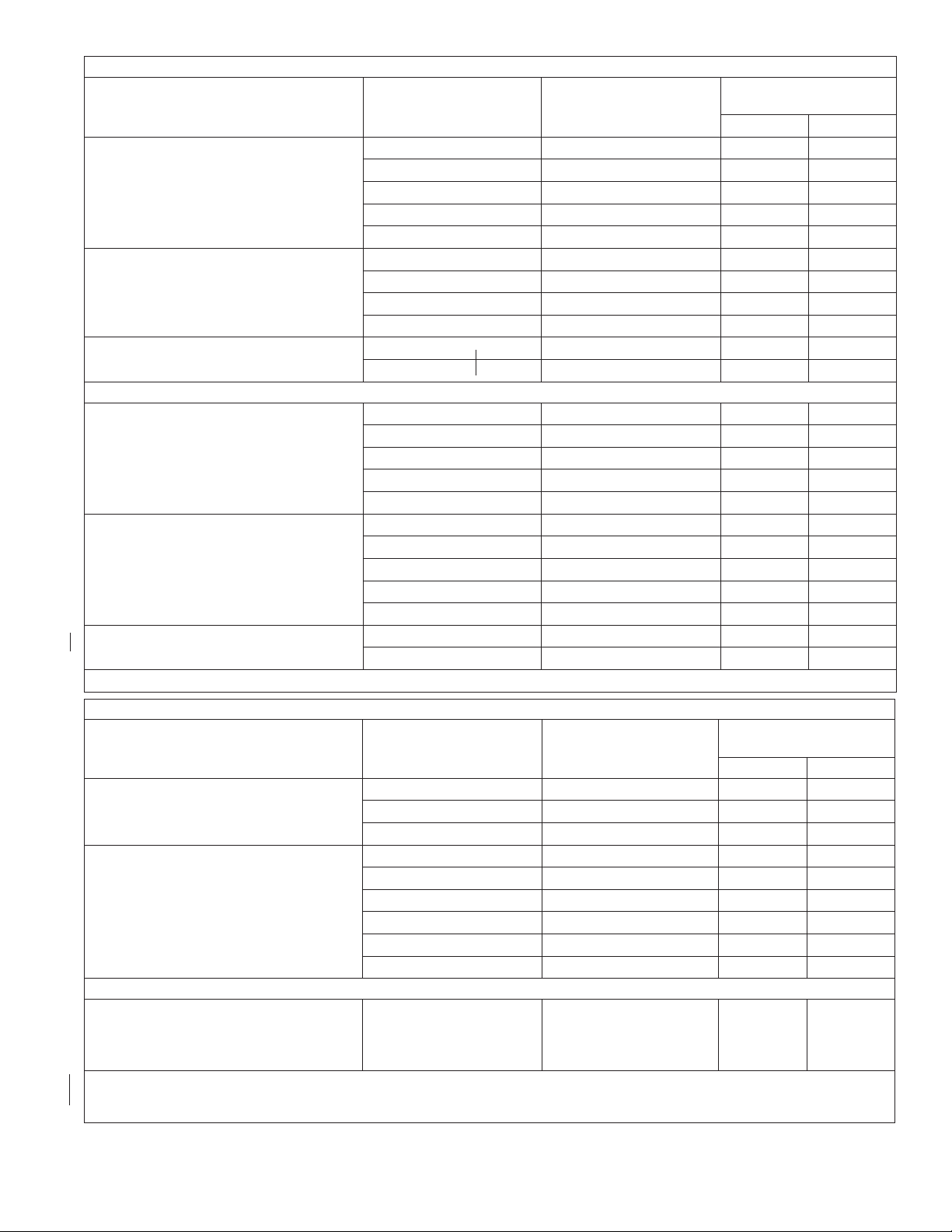

Reliable G Series User manual

Reliable

Reliable J112SS Series Manual

Reliable

Reliable GFR VELO–ECOH Manual

Reliable

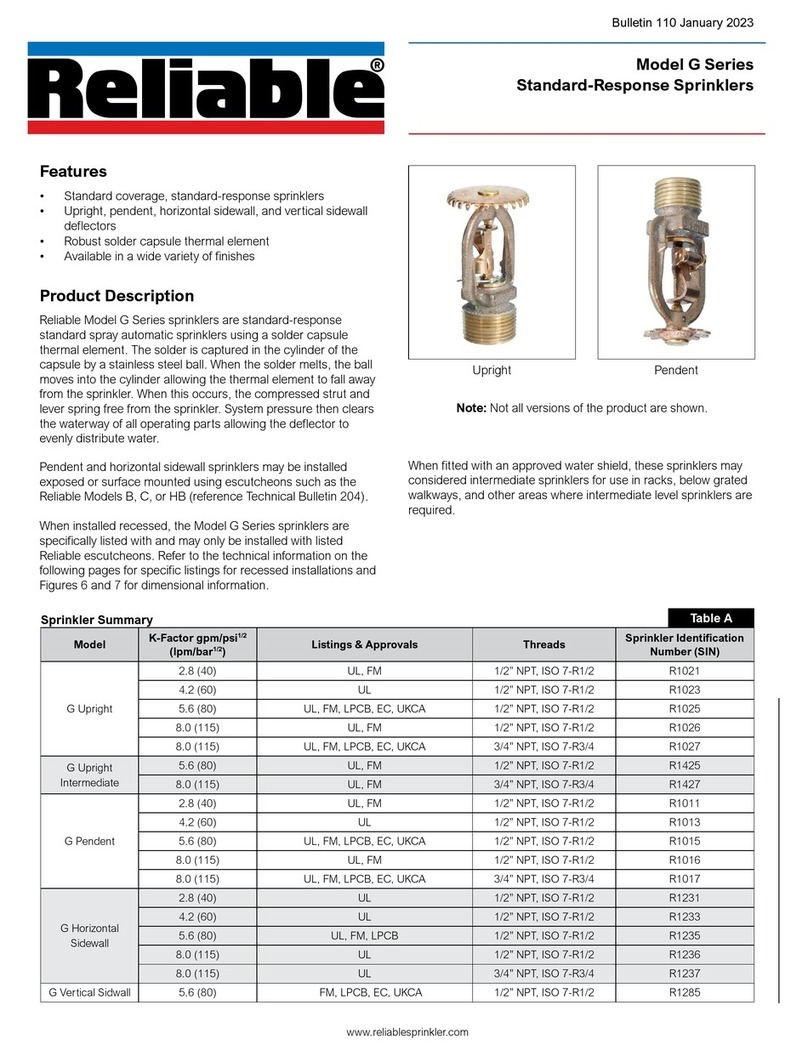

Reliable F1 Res 30 LL User manual

Reliable

Reliable F3QR56 User manual

Reliable

Reliable F1FR User manual

Reliable

Reliable DH80 Manual

Reliable

Reliable F1 LO Manual

Reliable

Reliable F1FR QREC Manual

Reliable

Reliable F1FR56-300 QREC Series User manual

Reliable

Reliable N25 User manual

Reliable

Reliable J112 Pendent Manual

Reliable

Reliable F3-80 Dry Pendent User manual

Reliable

Reliable F1FR-FS56 User manual

Reliable

Reliable KFR-CCS User manual

Reliable

Reliable Pantman F1 User manual

Reliable

Reliable H PrePak Maintenance manual

Reliable

Reliable JL-17 User manual

Reliable

Reliable G5 Series User manual

Popular Irrigation System manuals by other brands

Hunter

Hunter Institutional Series instructions

Cellfast

Cellfast 52-305 user manual

Tyco Fire Product

Tyco Fire Product Star Galaxy SGQR instruction manual

Tyco Fire Product

Tyco Fire Product CENTRAL A instruction manual

Oral Care Technologies

Oral Care Technologies Hydro Floss Instructions for use

Tyco Fire Product

Tyco Fire Product Gem F892 instruction manual

Toro

Toro 730 Series Installation and service instructions

Eden

Eden 97063-EDAMZ quick start guide

Tyco

Tyco TY-L Series quick start guide

Tyco Fire Product

Tyco Fire Product CENTRAL ELO-231 instruction manual

Johnson Controls

Johnson Controls tyco ESFR-17 manual

Victaulic

Victaulic VicFlex I-VICFLEX.AQC-U installation instructions