8

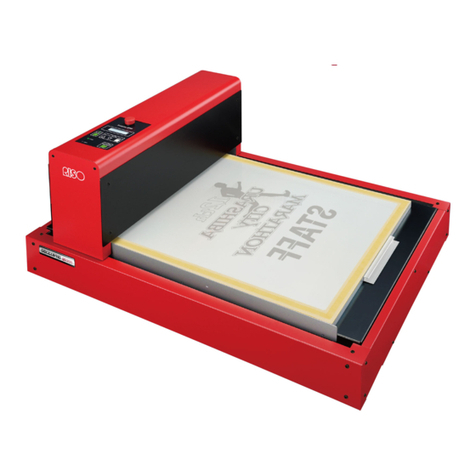

●Place the machine on a flat and stable surface (maxi-

mum of 3/8" / 10 mm differential allowed). Injury might

occur if the machine falls.

●Keep the machine away from dusty or humid environ-

ments. Failure to do so may result in fire.

• This machine is designed to be installed in a fixed

location.

• Avoid installing the machine in the locations listed

below.

Failure to observe this precaution may result in mal-

function or accident.

• Locations with exposure to direct sunlight and

bright locations such as that close to windows (if

such locations are unavoidable, shield windows with

curtains or the like)

• Locations subject to sudden temperature changes

• Hot and humid locations or cold and dry locations

• Locations with fire or heat, and locations directly

exposed to cold air, hot air, or radiant heat

• Locations with poor ventilation

• Locations with much dust

●Do not overload the electrical outlet or

extension cord, nor damage the power

cord by placing heavy objectson it or pull-

ing or bending it. Thiscan result in fire or

electric shock.

●Depending on the voltage used, the specificationsof

available power cordsand extension cordsvary. Erro-

neously using a power cord or extension cord may

result in fire or electric shock.

• The length of the power cord and the extension cord

must be within 14.75 feet / 4.5 m and 15 feet / 5 m,

respectively.

• If the Voltage Changeover Switch isin the 220 V to

240 V position when using the machine, use a cable

with specificationsof 250 V/5 A or more, and make

sure itslength iswithin 15 feet / 5 m.

• If the Voltage Changeover Switch isin the 100 V to

120 V position when using the machine, use a cable

with specificationsof 125 V/8 A or more, and make

sure itslength iswithin 15 feet / 5 m.

●Do not plug or unplug the power cord if your handsare

wet. Thiscan result in electric shock.

●Do not pull the power cord but hold the plug itself

when unplugging it. Thiscan damage the cord and

result in fire or electric shock.

●If the machine isnot used for a long period such as

holidays, be sure to disconnect the power plug from

the outlet for safety.

●Pull out the power plug from the electrical outlet more

than once a year and clean the prongsof the plug and

their surroundings. Dust collected on these areascan

result in fire

●Be sure to insert the power plug with a ground con-

ductor into the wall outlet with a ground receptacle.

Do not use the machine if it isnot grounded. It may

result in fire or electric shock.

Safety Guide

Thissection describesmattersyoushould know before using the machine, including

precautionson the location for installing the machine and on the power supply.

Be sure to read thissection before using the machine.

Installation

Power Connection

Ground Connection