.........................................................................................................................................................................................................................................................................................................................................................................................................................................................

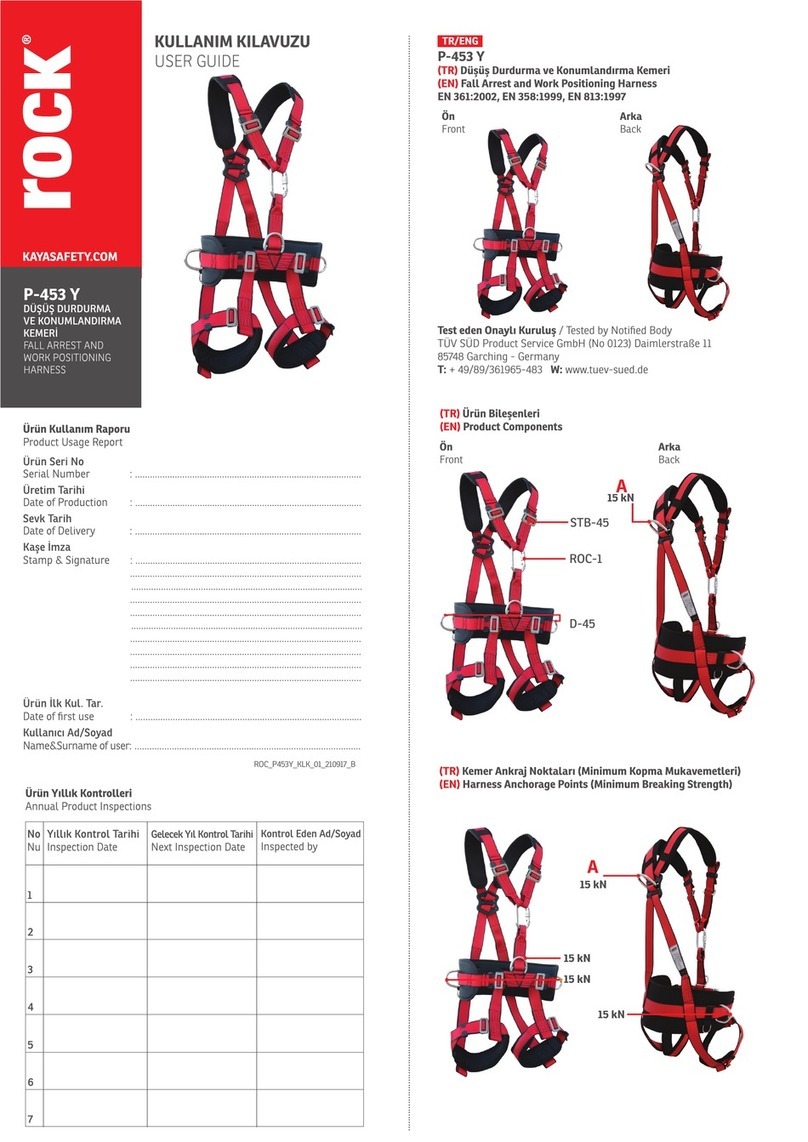

E- Size Selection

E-1- Waist

E-2- Leg

E-3- Height

E-4- Product Weight

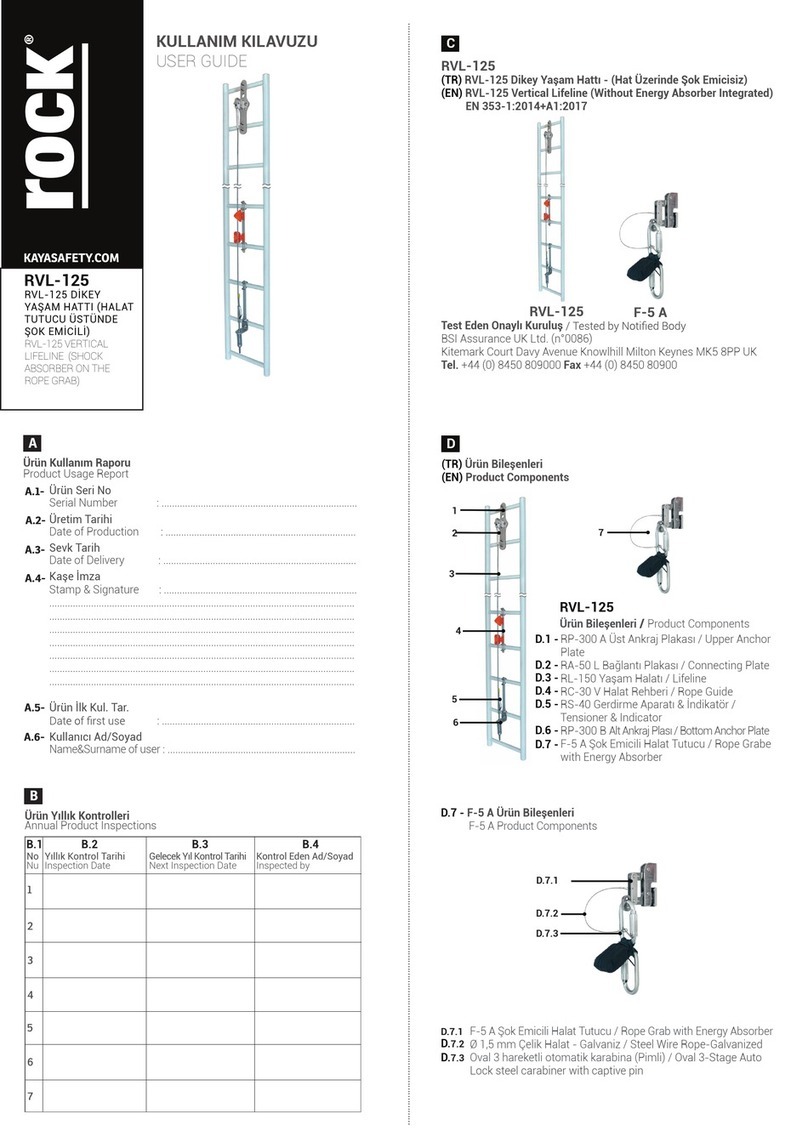

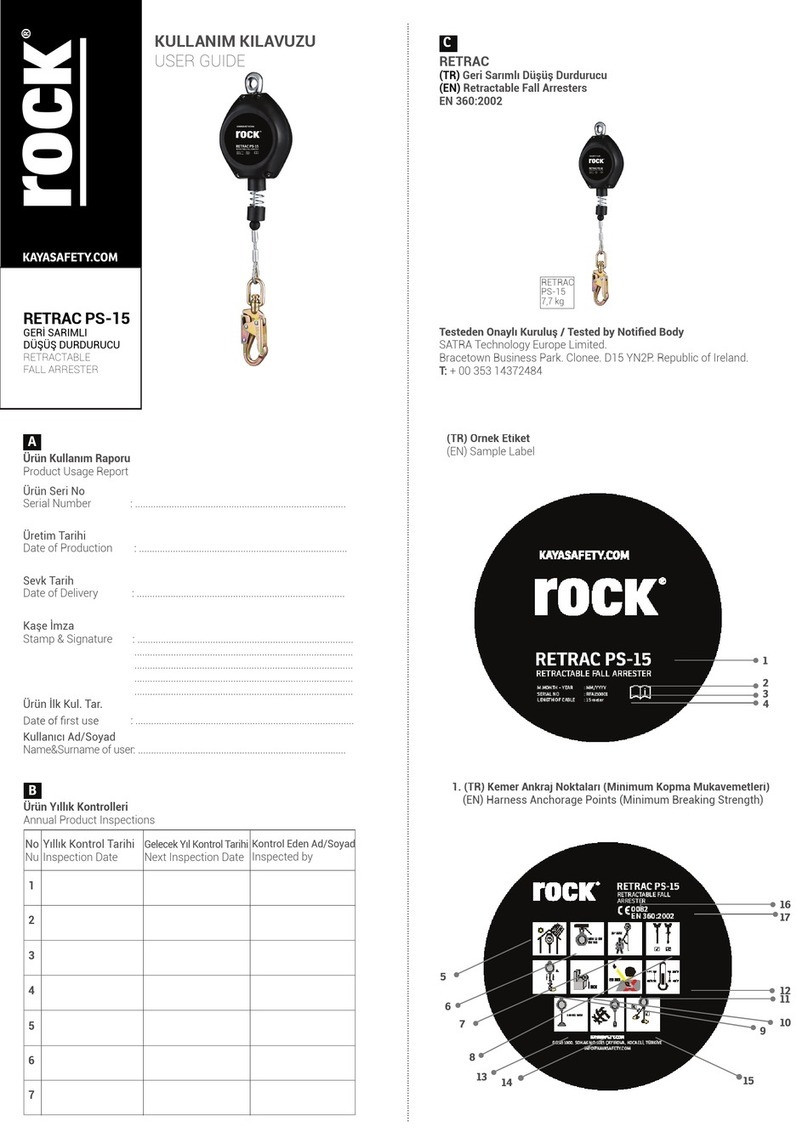

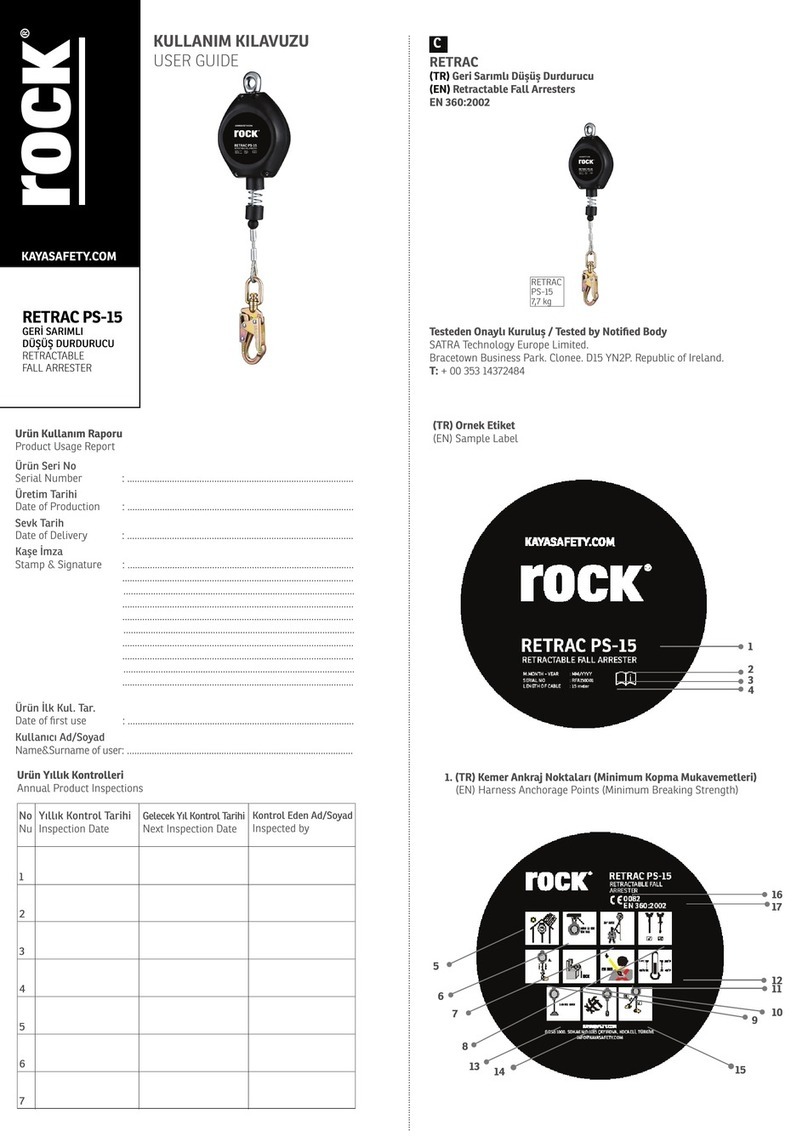

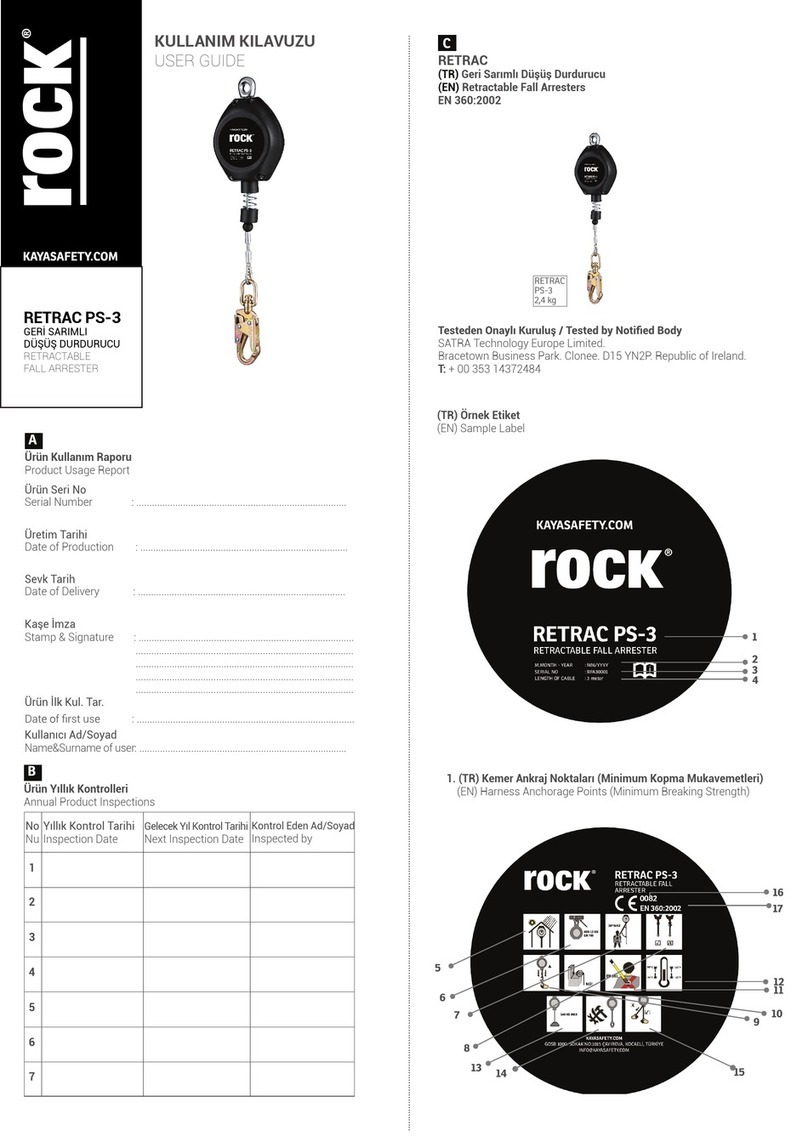

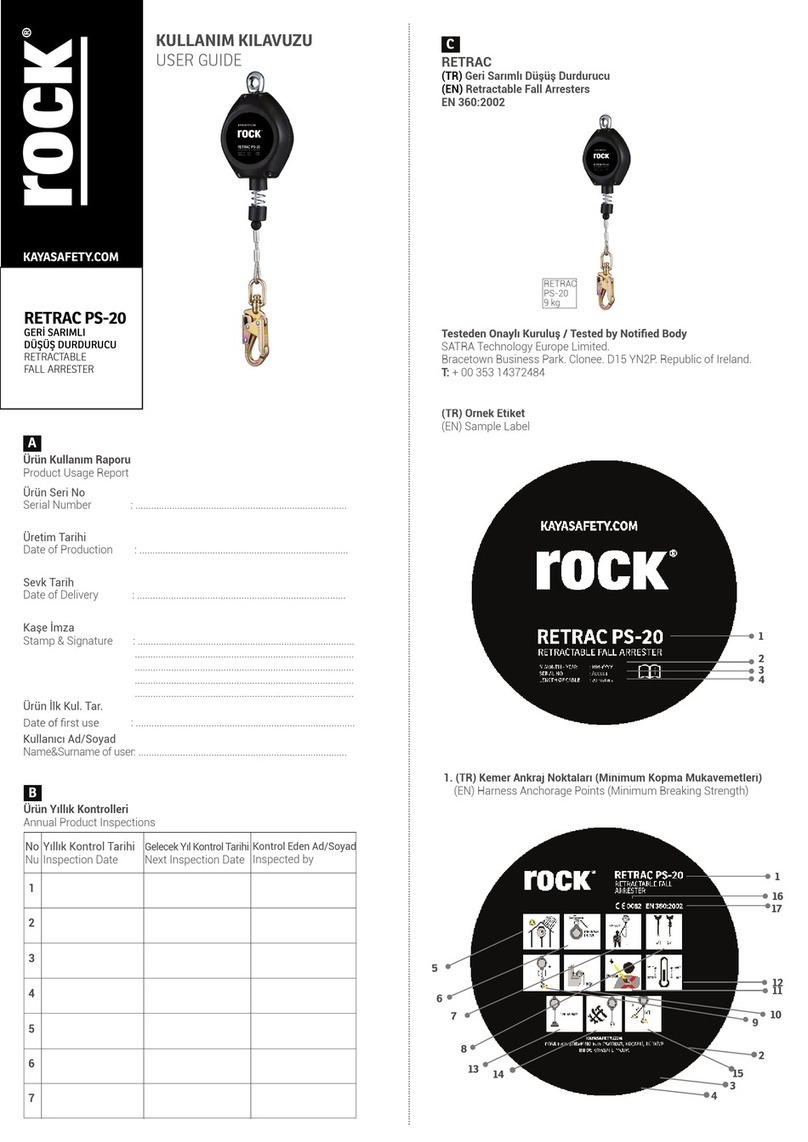

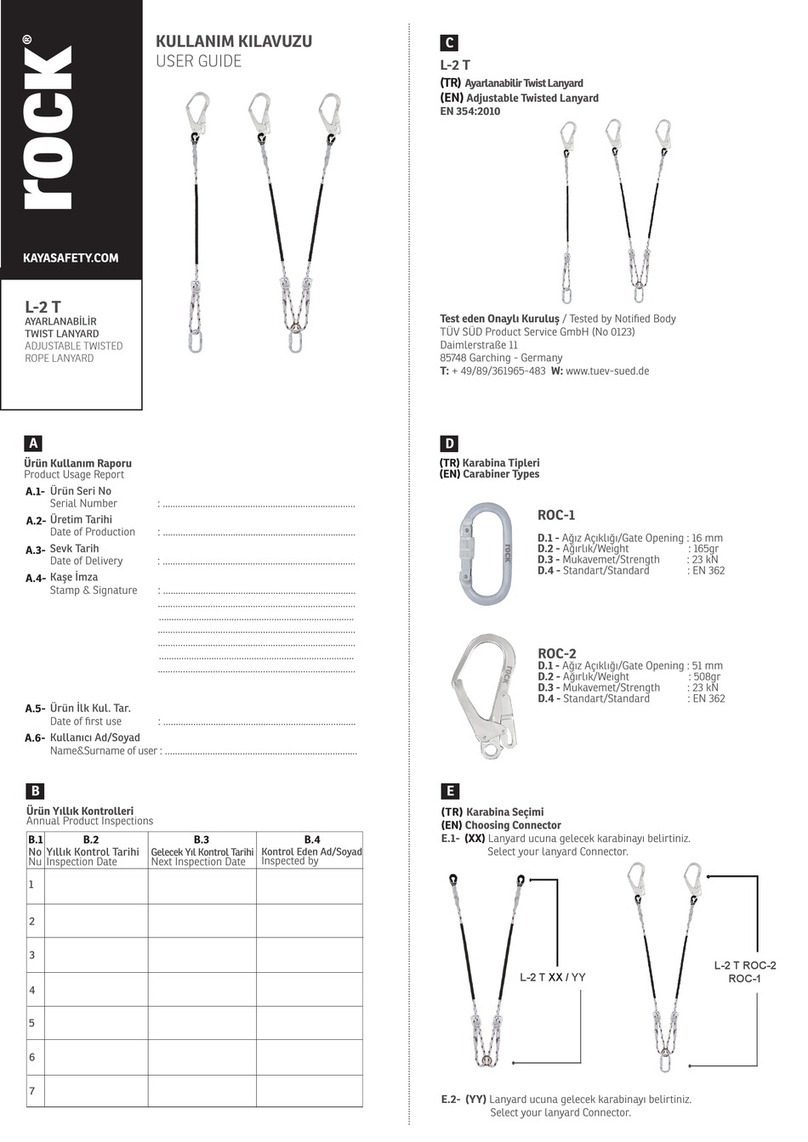

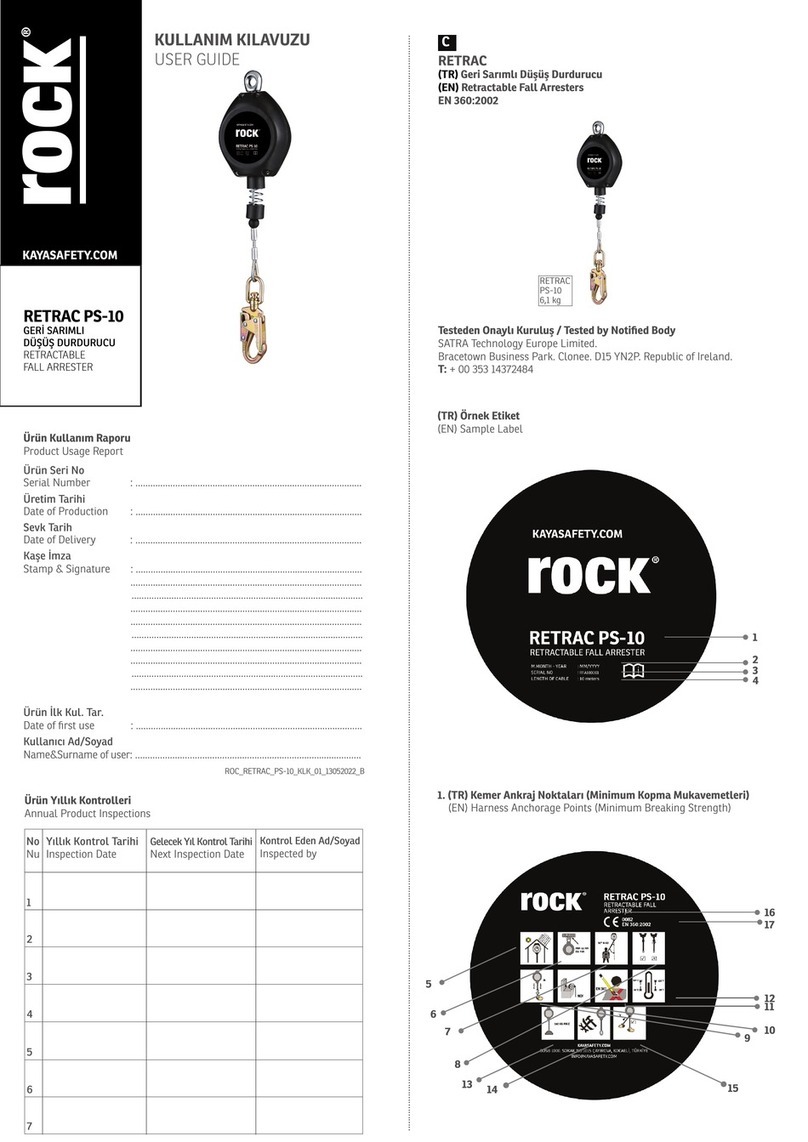

F- Product Label

F-1- Manufacturer

F-2- Product Name

F-3- Production Year

F-4- Serial Number

F-5- Tested Notified Body

F-6- Before Use Read User Guide

F-7- Standard

F-8- Product Code

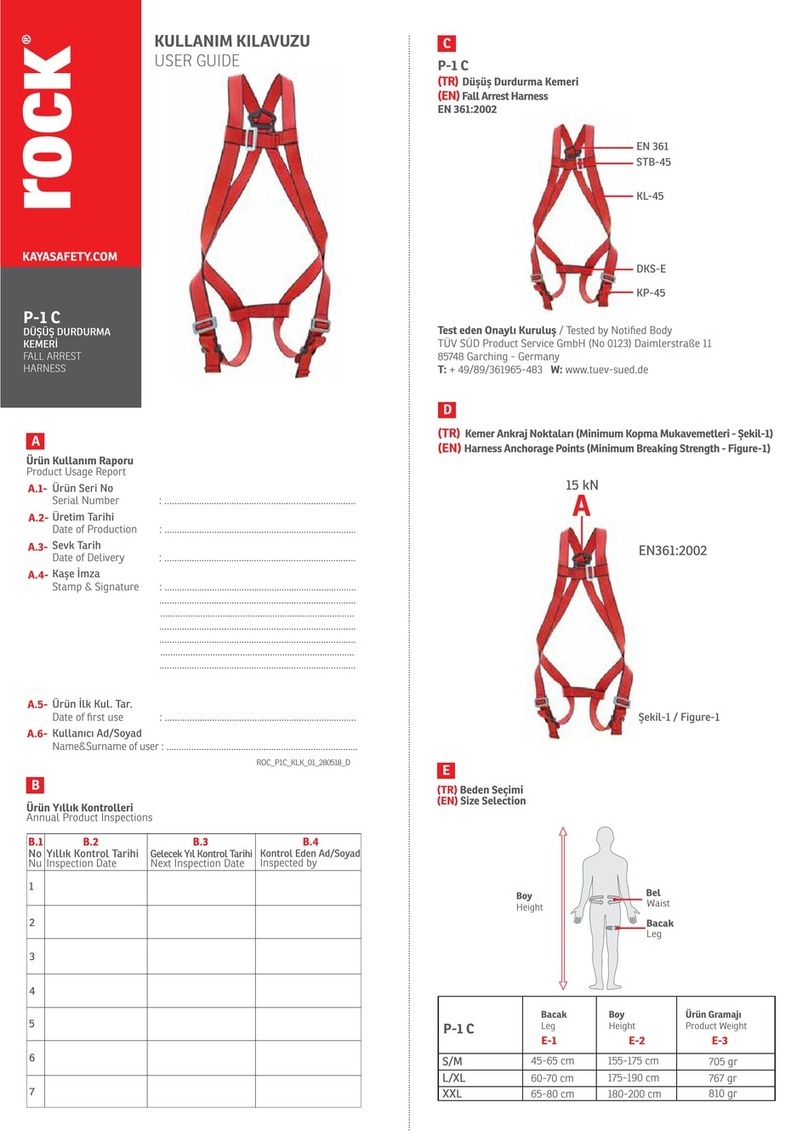

G- EN 361:2002 Fall Arrest Harness (Figure - 1)

H- EN 358:2018 Work Positioning and Restraint (Figure - 2)

I- Fall Clearance (Figure - 3)

J- Using Harness Buckles (Figure - J.1)

J.1.1- Harness Buckles SB-45

J.1.2- Connect the buckles together.

J.1.3- Pull the webbing to adjust.

K- Donning Full Body Harness (Figure-K.1)

K.1- Lift up harness and hold by back D-Ring. Ensure the straps are not

twisted. (Figure-K.1.1)

K.2- Pass your arm through the shoulder strap. (Figure-K.1.2)

K.3- Pass your other arm through the shoulder strap. (Figure-K.1.3)

K.4- Complete the sternal attachment connection. (Figure-K.1.4 -

Figure-K.1.5)

K.5- Complete the ventral attachment connection. (Figure-M.1.6 -

Figure-K.1.7- Figure-K.1.8)

K.6- Complete the leg strap connection. (Figure-K.1.9 - Figure-K.1.10 -

Figure-K.1.11)

K.7- Complete the other leg strap connection. (Figure-K.1.12 -

Figure-K.1.13)

K.8- The front look of the harness should be as it is shown in

Figure-K.1.14.

K.9- The rear look of the harness should be as it is shown in

Figure-K.1.15.

1. Caution

1.1- Working at height is one of dangerous activities that can lead to serious

injuries and death. It is under the responsibility of the user to learn and

apply it in practice of an appropriate techniques and safety methods and

apply these in practice. This full body harnesss should be used by only a

trained personnel or under the supervision of such personnel. Improper use

can cause serious injury and fatal accidents.

1.2-There must be a rescueplan that is to be applied in case of emergency

which may occur during working at height.

1.3-This safety harness is a component of a fall arrest system and is

aimed to prevent user from falling. This enhancement itself is not suitable

for working at height, it must also be used together with CE certificated

lanyards, shock absorbers, hooks and fall arresters.

2- Raw Material

This safety harness is made of;

Webbing for harness, and Yarns: Polyester

Waist pad: Polyester and Poliuretane

D ring and Buckle: Stainless Steel.

Webbing Holder and Back Plate : Polyprophilen

3. General Specifications

Personal Protective Equipment (PPE)

This full body harness enables the user to work safely by making a

connection to a secure point with an appropriate tool. This safety harness

is manufactured in comply with standards of EN 361:2002 and EN 358:2018

specified in PPE Regulation 2016/425 (EU).

4. Product Use

4.1- EN 361:2002 Fall Arrest Harness

* Full Body Fall Arrest Harness

When full body fall arrest harness is usedas fall arrester, all components of

the system should comply with the requirements of EN 363 (full fall arrest

systems). Remaining equipment which are anchoring points of harness must

comply with EN 795, Lanyards must comply with EN 354, Shock absorbers

must comply with EN 355, Carabiner must comply with EN 362.

*Dorsal D Ring and Sternal A/2 Loops; (Figure-1)

Use only dorsal D ring or two attachment loops marked A/2 of safety

harness with other equipment described in EN 363 (Shock absorber,

lanyard, fall arrest systems). These points were marked with “A” in order

to be recognized easily.

This harness was tested with 100 kg according to EN 361.

Warning: The adjustment and the tightness of the buckles and webbings

should be checked regularly during use

4.2- EN 358:2018 Work Positioning Harness

Always use side D ring with a positioning lanyard as shown in Figure-2.

Adjust the positioning lanyard with length adjustment device so as to work

comfortably with both hands free. The anchorage must be maintained

at or above waist level, and the lanyard kept taut and free movement is

restricted to a maximum of 0.6m. If the user is using this harness only for

work positioning, the waist belt is approved for a user, including tools and

equipment, with a weight of up to 150 kg.

Warning: Work Positioning Harness should not be used for fall arrest purposes

and that a waist belt should not be used if there is a foreseeable risk of the user

becoming suspended or being exposed to unintended tension by the waist belt.

Additional arrangements may be neccesary for work positioning or restraint

with collective means (e.g. safety nets) or personal means (e.g. fall arrest fall

systems in accordance with EN 363) of protection against falls from a height.

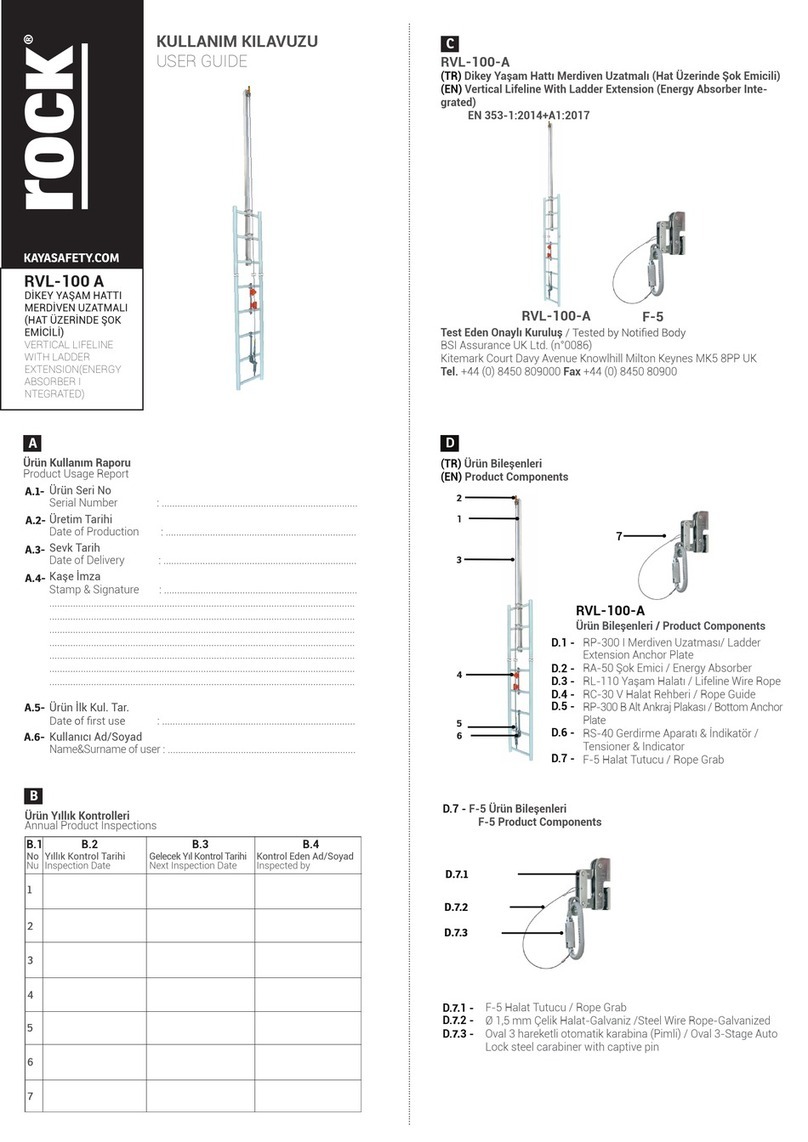

4.3- Fall Clearance = A+B+C+D

Figure - 3 ; Fall Clearance ( Calculation of fall clearance distance)

Clearance distance should be calculated in the working area for a possible fall.

In case of fall from height, user should be able to adjust the clearence distance

in order not to hit any object or ground.

Fall Clearance

Fall clearance is the height at which a user must attach to an anchorage to

avoid contact with a lower level. In order to calculate required fall clearance

distance the following measurements must be kept in mind.

A :Length of Fall Arrest System (Lanyard)

B :Length of the Lanyard after afall

C :Height of Suspended User

D : Safety Factor

5. Product Control and Validation

5.1 Before Every Single Use

Before the first use, the user should carry out a comfort and adjustability test

in a safe place to ensure that the correct size selection is made andthe sit

harness has sufficient adjustment and is of an acceptable comfort level for

the intended use;

Working at height equipment must be used as personalized. These products

must be controled on regular basis before and after each single use and

findings must be recorded into product control form. On an adequate lighted

environment apply following controls by lying the product down on a flat

surface;

• Webbings should be checked for cuts, abrasions, color change, broken stitches

and undue stretching.

• Buckles should be checked for signs of wear, cracks, deformation, corrosion or

other damages. They should function correctly and smoothly.

• D Rings and other metal parts should be checked for signs of wear, cracks,

deformation, corrosion or other damage.

• Connectors should be checked for sign of wear, cracks, deformation, corrosion,

dirt. The gate and the locking mechanisms should work easily and without any

problem. The gate should open and close completely.

• Labels should be secure and legible.

• During the controls if at least one of these deviation is found, usage of

the equipment should be suspended or retired and immediately send back

to producer for detailed inspection. No repair is allowed by unauthorised

person. Only manufacturer directions should be applied.

5.2 During Each Use

When use product with a system , make sure that all pieces of equipment in

the system are correctly positioned and compatible with each other.

6. Supplementary Information Regarding Standard; EN 365

6.1 Rescue Plan

A worker who has been incapacitated by an injury or medical condition and

who is suspended by the full body harness must be rescued immediately. So

you must always have a rescue plan for such emergency situations. For this

adequately trained personnel and rescue equipment must be on hand.

6.2 Anchor Point

The anchor point of the system comprises this product should preferably be