Rodcraft Pneumatic Tools GmbH

Page 4 from 6

Rodcraft Pneumatic Tools GmbH

4.2

General safety references

The jacking equipment are built and are reliable in service delivered after the newest state of the art. Under the function it does not give to be taken off

or protected places and parts those can without the function and operability substantially impair. A good personal safety practice of the operator is

necessary from there for the own protection and for the protection from damage to the equipment

The jacking equipment may be used and operated only in the context of the conditions specified in the achievement and supply contract. Retrofits,

changes or changes of the devices are forbidden in principle. They require in any case the consultation with the manufacturer.

If dangers and risks should show up in the enterprise (remainder), which are not described in this manual, the operator is obligated to communicate

these to the manufacturer.

4.3

Special safety references

-

The load which can be lifted may never exceed the capacity of the jacking equipment.

-

Ranking under load is forbidden

-

The jacking equipment over the max. stroke indicated on the vehicle identification plate do not operate.

-

Park the vehicle and/or the load on a sturdy, even, horizontal surface, which can be raised, and secure you the wheels over for movements to

exclude.

-

Never use the jacking equipment on averse surfaces

-

The jacking equipment always in such a way position that its operation is excluded from underneath the vehicle.

-

The use of the jacking equipment is only using additional safety stays, as e.g. permits supporting blocks.

-

Before the employment of the jacking equipment that no persons are in the vehicle, the emergency brake is to be guaranteed attraction and the

engine is switched off.

-

Always take the vehicle book to the assistance for the correct points at the vehicle.

-

If no points are indicated, then the jacking equipment in the center of the load position. Unkorrektes positioning of the jacking equipment can lead to

tilting the load. This can lead to damage of the load and/or the jacking equipment as well as to injuries of the operator.

-

Around a movement of the vehicle during the work with the jacking equipment to exclude all appropriate measures must be met.

-

The jacking equipment never misused use.

-

As additional safety precaution the jacking equipment are equipped with an overload valve, which is factory-installed adjusted. This valve may be

never adjusted.

-

During neglect of these basic rules the operator can injure itself or the load. and/or the jacking equipment to be damaged.

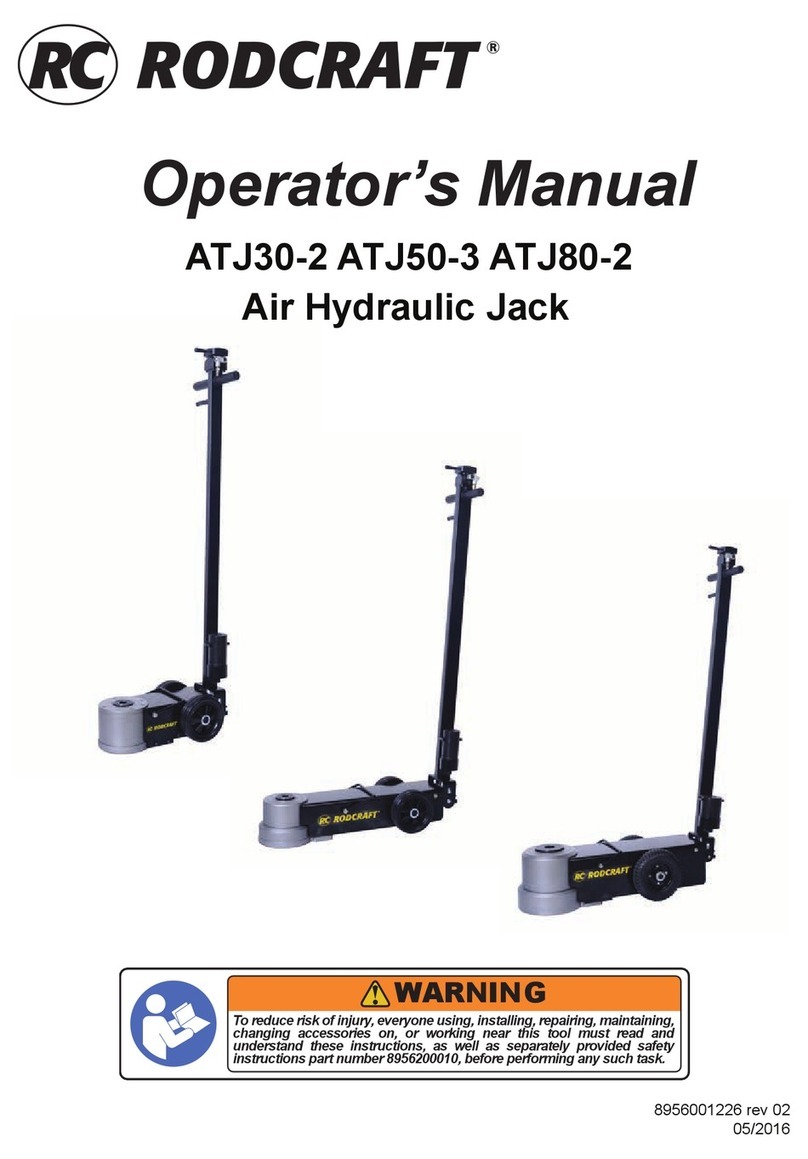

5

Start-up

•

It opens and controls the packing over to guarantee that the jacking equipment exhibits no transport damages and all parts specified in the

transmittal sheet is present. Before the start-up of the jacking equipment a visual inspection must be accomplished, in order to determine leakages,

damages, loose or missing parts.

•

Before employment of the jacking equipment it is to be aired out necessarily the hydraulic system. The lever into the admission put and

with the screw provided fasten.

•

Subsequently, turn, in this position left and several times pump the lever button in the clockwise direction to a complete stop. Turn afterwards the

lever button against the clockwise direction. Now the jacking equipment is operational. All models have a foot pedal that facilitates the lifting operation

up to the load. The correct points at the vehicle take you please from the vehicle book.

•

Turn the lever button against the clockwise direction for lowering the load slowly. Our jacking equipment are equipped with a safety device, which

prevents overloads. After the sinking procedure on the fact always it respects that the lifting arm went back completely.

6

Work with the jacking equipment

Jacking equipment is only one lifting device and may for transporting and/or loading a vehicle be never used.

Ranking under load is forbidden.

Use equipment only for the descriptive application, exclude every other use we expressly! ! !

For injuries and damage due to inappropriate and misused application and/or from offence against the safety regulations take over we do

not result adhesion or a guarantee.