MC16-PAC-2-KIT Installation Manual.doc 2019-05-30

Roger Access Control System

MC16-PAC-2-KIT Installation Manual

Firmware version: n/a

Document version: Rev. B

This document contains minimum information that is necessary for initial setup

and installation of the kit. The detailed description of configuration parameters

and functionalities of all components is specified in respective Operating

manuals available at www.roger.pl.

INTRODUCTION

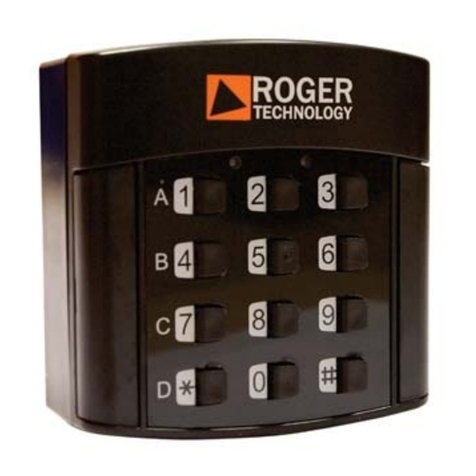

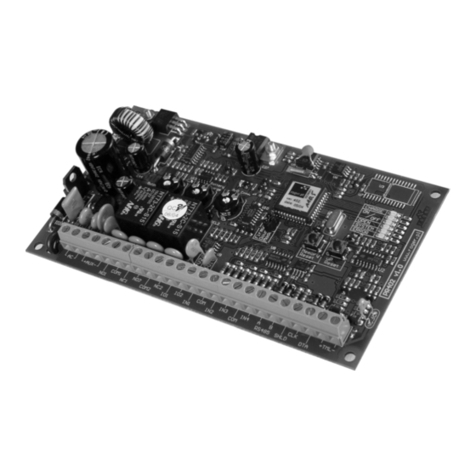

MC16-PAC-2-KIT is designed to control two doors in RACS 5 system. Both

doors can be read-in or read-in/out type when equipped with MCT series readers

(RS485). The kit includes MC16-PAC-2 access controller, MCX2D expander and

ME15 metal box with PS2D power supply unit. The box is adapted to installation

of 7Ah battery for emergency supply. All elements of controlled door including

readers and door locks can be supplied from the kit.

CONFIGURATION WITH ROGERVDM PROGRAM

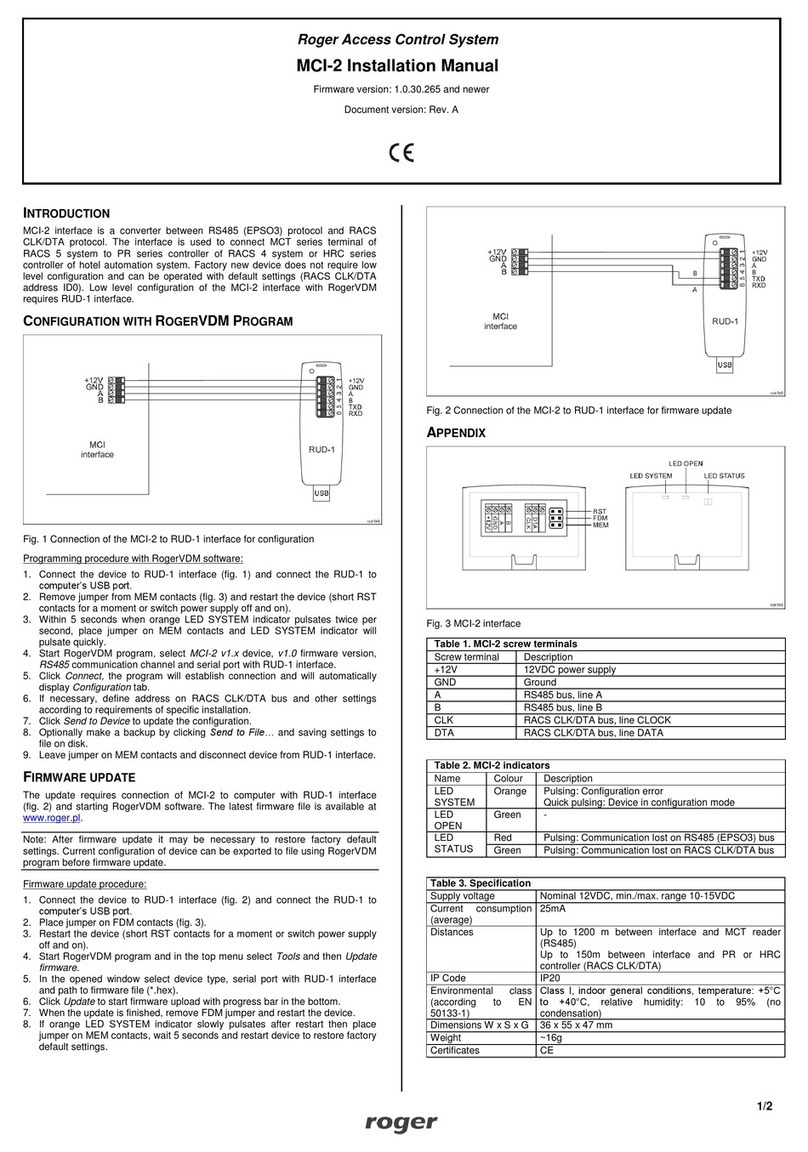

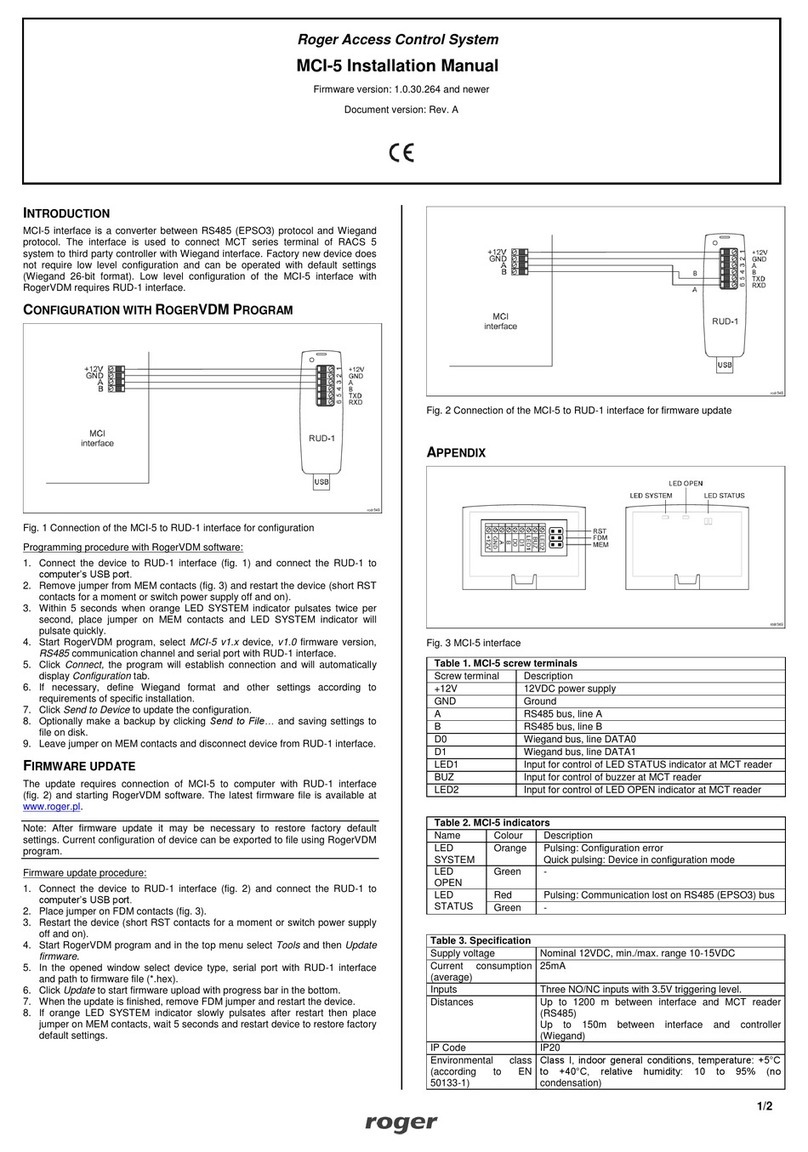

Low level configuration with RogerVDM software mainly concerns MC16

controller. Additionally it is necessary to define individual addresses for MCT

series readers according to their installation manuals.

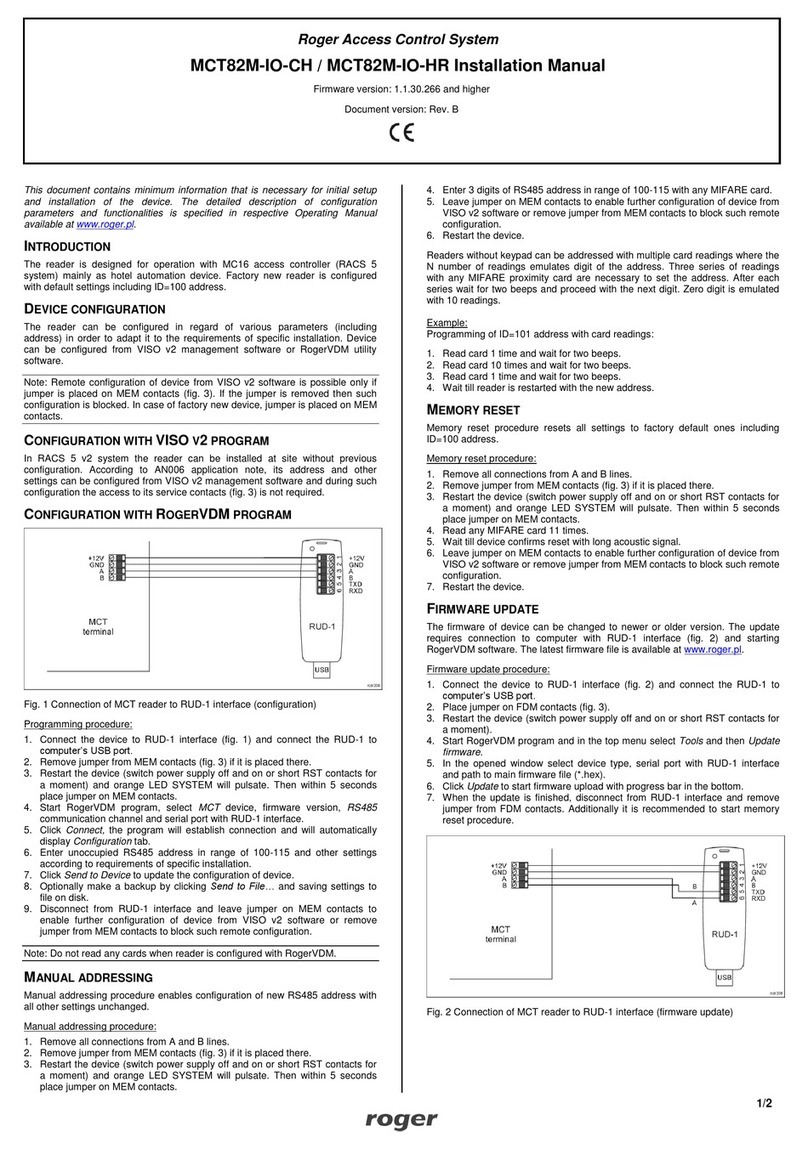

MC16 programming procedure with RogerVDM software:

1. Connect the controller to Ethernet network and define the IP address of your

computer in the same subnetwork as the controller with 192.168.0.213

default IP address.

2. Start RogerVDM program, select MC16 v1.x device, the latest firmware

version and Ethernet communication channel.

3. Select from the list or enter manually the IP address of controller, enter 1234

communication key and start the connection with the controller.

4. In the top menu select Tools and then Set communication key to define your

own password for the controller.

5. In the main window specify your own IP address of the controller.

6. Optionally enter comments for controller and its object to facilitate their

identification during further configuration of the system.

7. Optionally backup settings clicking Send to File…

8. Click Send to Device to update the configuration of controller and disconnect

by selection of Device in the top menu and then Disconnect.

MEMORY RESET

Memory reset procedure resets all settings to default ones and results in

192.168.0.213 IP address and empty communication key.

MC16 memory reset procedure:

1. Disconnect power supply

2. Short CLK and IN4 lines.

3. Restore power supply, all LEDs will flash and wait min. 6s.

4. Remove connection between CLK and IN4 lines, LEDs will stop pulsating and

LED2 will be on.

5. Wait approx. 1.5 min till LED5+LED6+LED7+LED8 are pulsating.

6. Restart the controller (switch power supply off and on)

7. Start RogerVDM and make low level configuration.

FIRMWARE UPDATE

New firmware can be uploaded to the controller with RogerVDM software. The

latest firmware file is available at www.roger.pl.

MC16 firmware update procedure:

1. Connect with the controller using RogerVDM software.

2. Backup settings by clicking Send to File…

3. In the top menu select Tools and then Update firmware.

4. Select firmware file and then click Update.

5. After firmware update wait till LED8 is pulsating.

6. Make or restore low level configuration in RogerVDM software.

Note: During the firmware update process, it is necessary to ensure continuous

and stable power supply for the device. If interrupted, the device may require

repair by Roger.

POWER SUPPLY

The kit is supplied from PS2D power supply unit. The metal box offers space for

installation of typical 7Ah backup battery which is connected to BAT+ and BAT-

terminals of MCX2D expander.

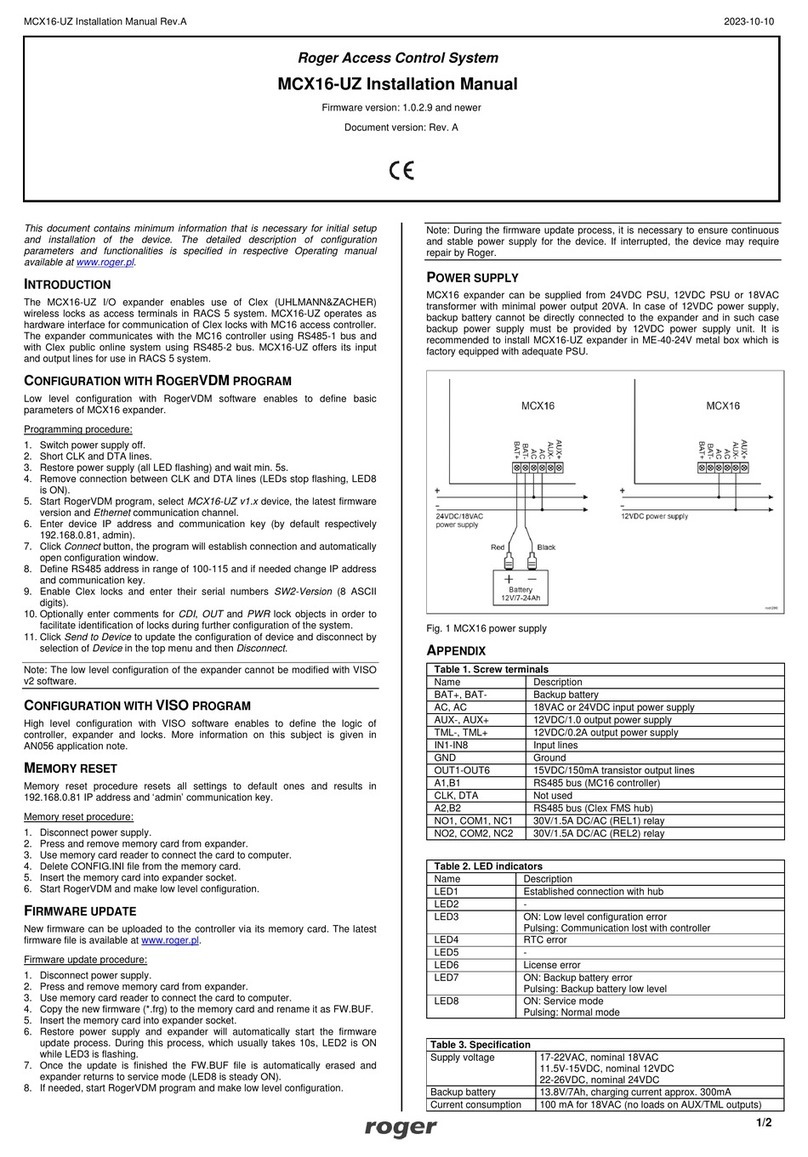

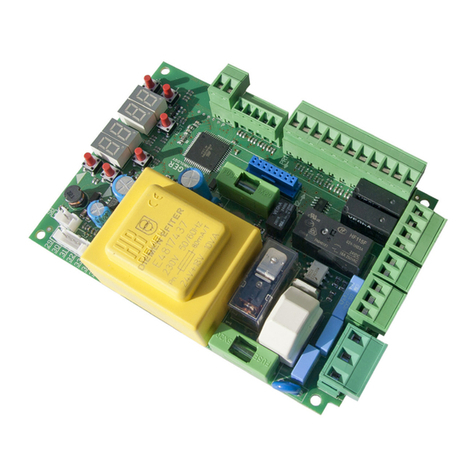

Fig. 1 MC16-PAC-2-KIT

The installation can be done only by qualified person with all

necessary certificates concerning connection and maintenance

of 230VAC and low voltage networks.

Prior to starting the installation it is necessary to ensure that

230 VAC circuit is disconnected. All works inside the box must

be carried out with 230VAC supply voltage disconnected.

It is forbidden to use the kit without properly executed and

operational earthing system.

TAMPER DETECTOR

The metal box is equipped with door contact which can be connected to one of

the inputs (e.g. IN8) and GND terminal of the controller. The anti-sabotage

function can be assigned to the input within high level configuration of the

system.

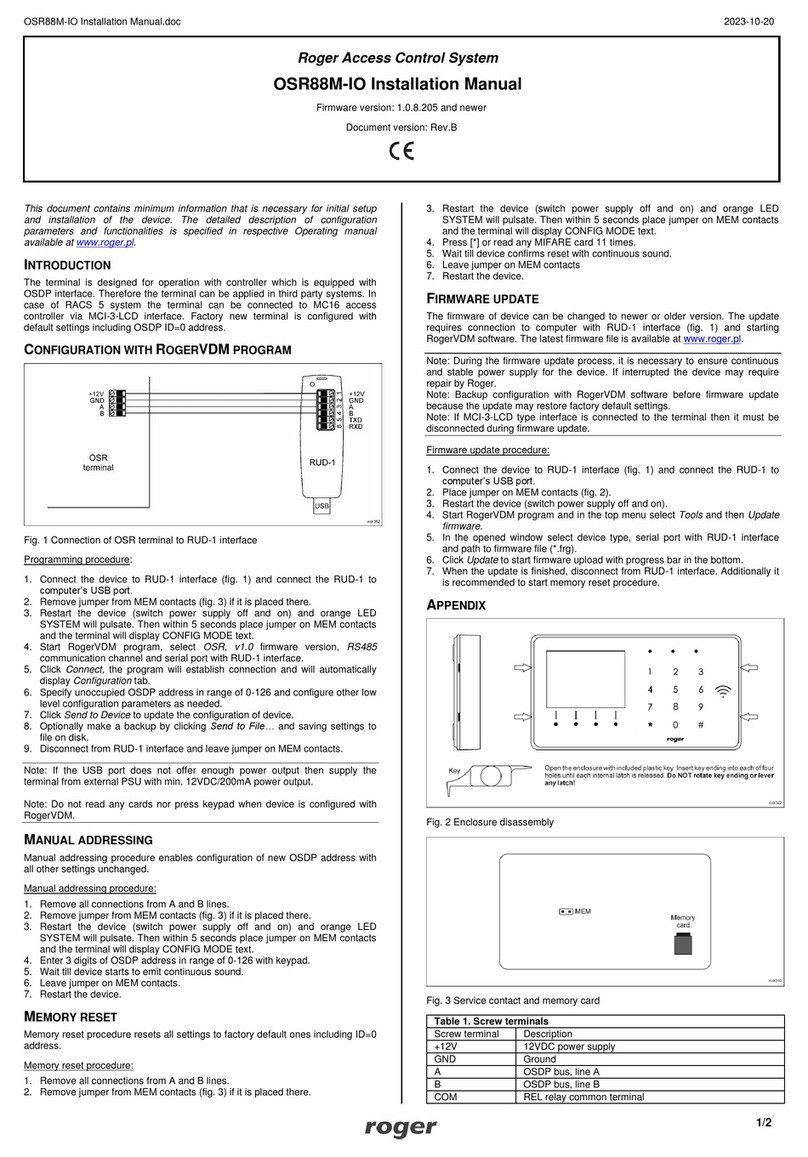

APPENDIX

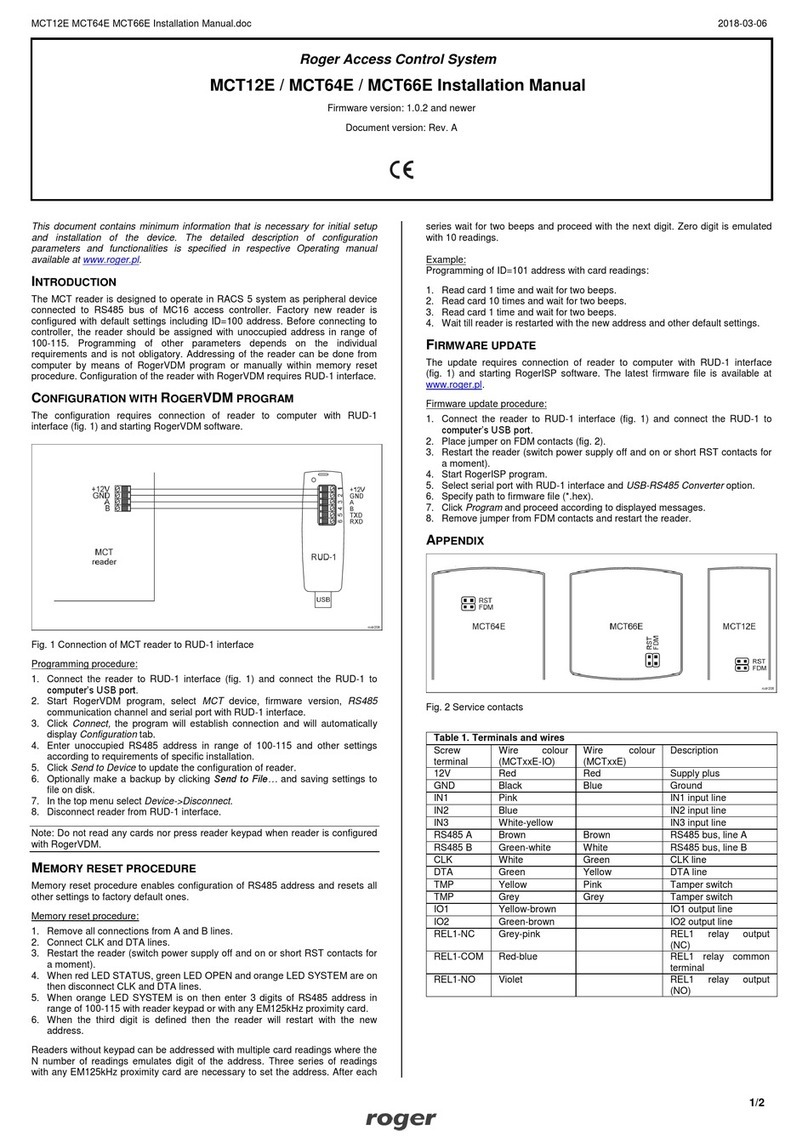

Table 1. MC16 screw terminals

15VDC/150mA transistor output lines

30V/1.5A DC/AC (REL1) relay

30V/1.5A DC/AC (REL2) relay

Table 2. MCX2D screw terminals

13.8VDC input power supply

13.8VDC/0.2A output power supply (for general

purpose)

13.8VDC/0.2A output power supply (for controller)

RS485 bus (for controller)

13.8VDC/0.2A output power supply (for readers)

13.8VDC/1.0A output power supply (for door lock)

15VDC/1A transistor output line (door lock)

15VDC/1A transistor output line (alarm signalling