MCT88M-IO Installation Manual 2021-10-01

Roger Access Control System

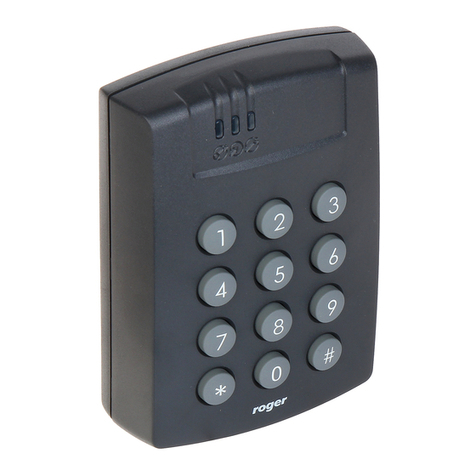

MCT88M-IO Installation Manual

Firmware version: 1.0.6.193 and newer

Document version: Rev. I

This document contains minimum information that is necessary for initial setup

and installation of the device. The detailed description of configuration

parameters and functionalities is specified in respective Operating manual

available at www.roger.pl.

INTRODUCTION

The terminal is designed for operation with MC16 access controller (RACS 5

system). Alternatively the device can communicate with virtual controller via

Ethernet (LAN) and operate as PoS terminal or assets tracking terminal. Factory

new terminal is configured with default settings including ID=100 address.

DEVICE CONFIGURATION

The terminal can be configured in regard of various parameters (including

address) in order to adapt it to the requirements of specific installation. Device

can be configured from VISO v2 management software or RogerVDM utility

software.

Note: Remote configuration of device from VISO v2 software is possible only if

jumper is placed on MEM contacts (fig. 3). If the jumper is removed then such

configuration is blocked. In case of factory new device, jumper is placed on MEM

contacts.

CONFIGURATION WITH VISO V2PROGRAM

In RACS 5 v2 system, when connected to MC16 controller, the terminal can be

installed at site without previous configuration. According to AN006 application

note, its address and other settings can be configured from VISO v2

management software and during such configuration the access to its service

contacts (fig. 3) is not required.

CONFIGURATION WITH ROGERVDM PROGRAM

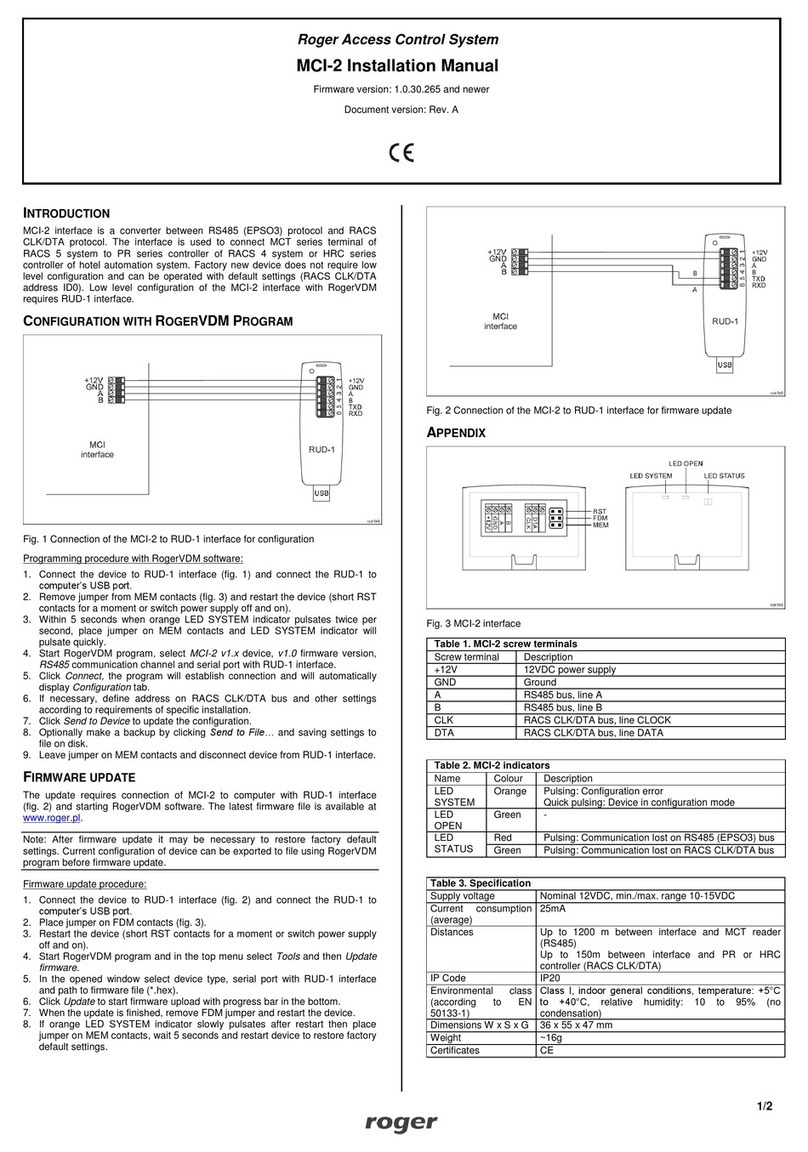

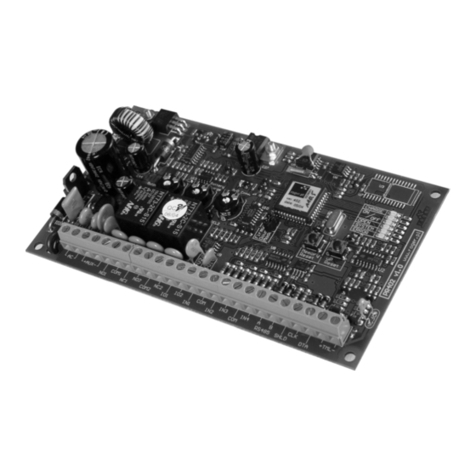

Fig. 1 Connection of MCT reader to RUD-1 interface (configuration)

Programming procedure:

1. Connect the device to RUD-1 interface (fig. 1) and connect the RUD-1 to

computer’s USB port.

2. Remove jumper from MEM contacts (fig. 3) if it is placed there.

3. Restart the device (switch power supply off and on) and orange LED

SYSTEM will pulsate. Then within 5 seconds place jumper on MEM contacts

and the terminal will display CONFIG MODE text.

4. Start RogerVDM program, select MCT device, v1.0 firmware version, RS485

communication channel and serial port with RUD-1 interface.

5. Click Connect, the program will establish connection and will automatically

display Configuration tab.

6. Select RS485 communication interface and specify unoccupied RS485

address in range of 100-115 or select Ethernet communication interface and

specify IP address. Configure other low level configuration parameters as

needed.

7. Click Send to Device to update the configuration of device.

8. Optionally make a backup by clicking Send to File… and saving settings to

file on disk.

9. Remove jumper from MEM contacts and disconnect device from RUD-1

interface.

Note: If the USB port does not offer enough power output then supply the

terminal from external PSU with min. 12VDC/200mA power output.

Note: Do not read any cards nor press keypad when device is configured with

RogerVDM.

MANUAL ADDRESSING

Manual addressing procedure enables configuration of new RS485 address with

all other settings unchanged.

Manual addressing procedure:

1. Remove all connections from A and B lines.

2. Remove jumper from MEM contacts (fig. 3) if it is placed there.

3. Restart the device (switch power supply off and on) and orange LED

SYSTEM will pulsate. Then within 5 seconds place jumper on MEM contacts

and the terminal will display CONFIG MODE text.

4. Enter 3 digits of RS485 address in range of 100-115 with keypad.

5. Wait till device starts to emit continuous sound.

6. Leave jumper on MEM contacts to enable further configuration of device from

VISO v2 software or remove jumper from MEM contacts to block such remote

configuration.

7. Restart the device.

MEMORY RESET

Memory reset procedure resets all settings to factory default ones including

ID=100 address.

Memory reset procedure:

1. Remove all connections from A and B lines.

2. Remove jumper from MEM contacts (fig. 3) if it is placed there.

3. Restart the device (switch power supply off and on) and orange LED

SYSTEM will pulsate. Then within 5 seconds place jumper on MEM contacts

and the terminal will display CONFIG MODE text.

4. Press [*] or read any MIFARE card 11 times.

5. Wait till device confirms reset with continuous sound.

6. Leave jumper on MEM contacts to enable further configuration of device from

VISO v2 software or remove jumper from MEM contacts to block such remote

configuration.

7. Restart the device.

FIRMWARE UPDATE

The firmware of device can be changed to newer or older version. Firmware can

be uploaded to the terminal by means of included memory card. The latest

firmware file is available at www.roger.pl.

Note: During the firmware update process, it is necessary to ensure continuous

and stable power supply for the device. If interrupted the device may require

repair by Roger.

Note: Backup configuration with RogerVDM software before firmware update

because the update will restore factory default settings.

Firmware update procedure:

1. Disconnect power supply.

2. Press and remove memory card from socket (fig. 3).

3. Using memory card reader, copy main firmware (*.frg) to the card and

rename it as FW.BUF.

4. Insert the card into socket.

5. Connect power supply. During firmware update the LED STATUS (red) will

pulsate and the LED OPEN (green) will be switched on and after firmware

update the LED SYSTEM (orange) will pulsate.

6. Restart the device (switch power supply off and on) and orange LED

SYSTEM will pulsate. Then within 5 seconds place jumper on MEM contacts

and the terminal will display CONFIG MODE text.

7. Start RogerVDM program and perform low level configuration or restore the

configuration from backup file using Read from File… command.