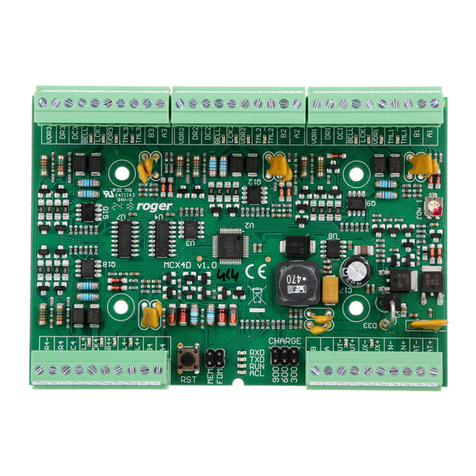

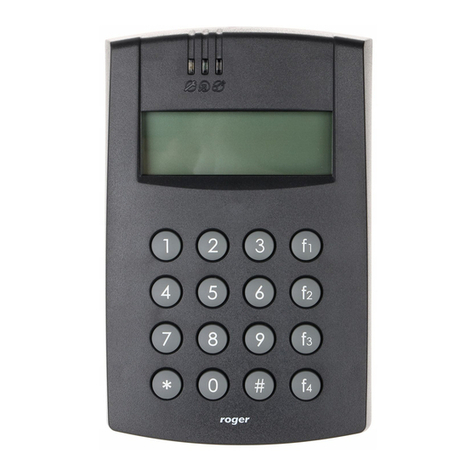

Introduction

This document contents minimum information required for electrical installation of PR302 access

controller.

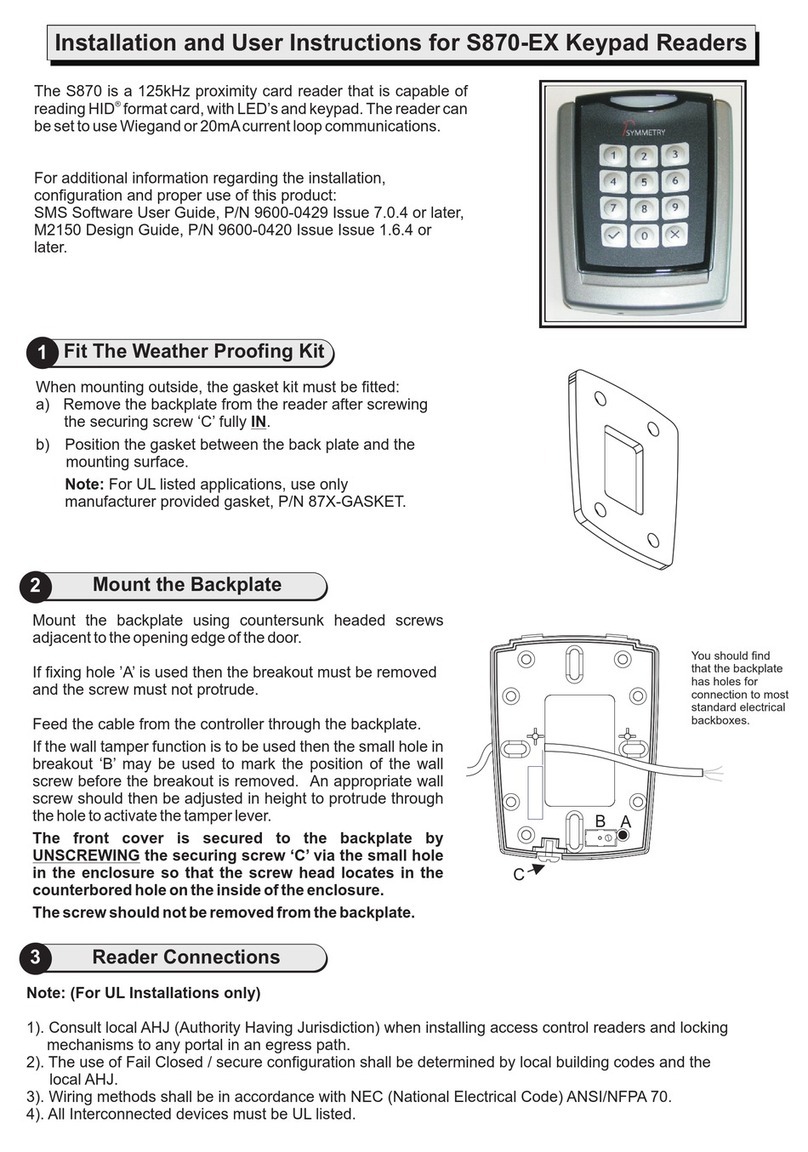

Installation

The PR302 can be installed in indoor location only. All electrical connections must be made before

power supply will be applied. Factory new unit is configured for address ID=00 and has programmed

MASTER PIN (1234) and MASTER card (delivered with the new device). The MASTER card/PIN can

be used for initial testing of the controller - the single use of MASTER card/PIN activates

momentarily REL1 output (for approx. 4s); double, consecutive use of MASTER card/PIN changes

controller’s arming mode and switches IO1 output to reverse state.

All devices working in one access system and connected to the same RS485 communication bus

should have common minus (common GND). This can be achieved by connecting all supply minuses

using additional (separate) wire or connecting each supply minus with earth, however the second

method might create problems when electrical potentials of the earth are not the same in different

parts of the electric installation.

Note: It is forbidden to short positive outputs (DC+) from various sources of power and/or other DC

outputs available in the system.

Setting address

Before controller will be connected to communications bus it should be configured to individual

address (ID number=00..99). The controller’s address can be set manually using Memory Reset

procedure or from PC computer. In order to set/change controller’s address from PC connect it to

any free COM port and then using PR Master program enrol it to database. Once the unit is found by

PR Master use relevant command to change its address and then disconnect it from PC and connect

to designated access installation.

Note: Connecting two or more controllers with the same address will cause communications conflict

on the communication bus.

Power supply

Controller requires 10-15VDC supply and consumes 100mA average current. The power source

should provide DC voltage free of interferences. Using poor quality switched mode power sources

can cause reduction of card reading distance. Always carefully calculate wire gauge used to supply

access controller, note that amount of current required by controller can rise momentary up to

200mA. The GND input to controller is also reference ground for RS485 com. bus and for all signal

lines used in controller.

Door Lock

In most cases door locks are inductive type loads and generate strong voltage surges when

switching to off state. This phenomenal can corrupt electronic circuits and change its behaviour. In

order to protect access controller from these effects, every inductive load (like door lock or any

other coil) should be protected with silicon diode (e.g. 1N4007) connected as close as possible to the

switched device. Also, door locks should be wired using separate pair of wires connected directly to

the source of power.