4

3.2 Lifting unit

It is composed of four hydraulic cylinders

connected by rigid and flexibles tubes.

The lifting unit is controlled by an electric

panel placed on an electric cabinet (5) containing

the hydraulic unit.

3.3 Safety devices

The safety devices are composed of:

•

double, hydraulic circuit

•

two safety solenoid valves

•

flow control valve adjusts descent speed

•

automatically activated micros witch stops

descent travel thus acting as foot guard

•

Flow control valve just in case the hose broken

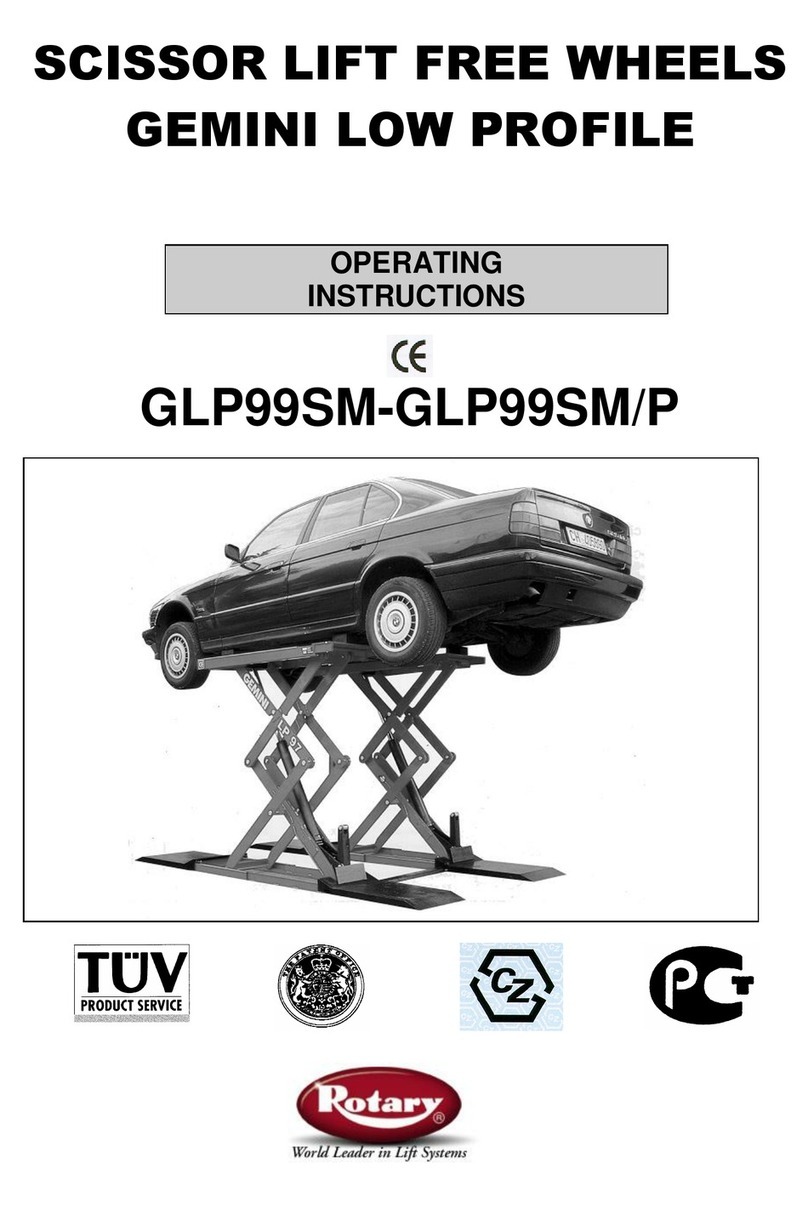

3.4 Intend use

The scissor lift may only be used:

•

In indoor areas for lifting unoccupied motor

vehicles.

•

For lifting vehicles with a max. load capacity of

3000KG

•

If the weight is distributed correctly. By default,

the load should be centered in the direction of

motion. If the main load (e.g. engine) is however

at the front or the back, the following applies:

at front max. 3/5,

at back 2/5 of load or vice versa.

•

With correctly aligned, adjustable runways. The

vehicle must be approximately centered on the

two platforms.

•

In accordance with the technical data in

Chapter 4, in technically sound condition.

3.5 Incorrect use, incorrect behavior

Incorrect behavior presents a residual risk to

the life and health of the people working in the

lift area.

The manufacturer assumes no liability for

damage resulting from use other than the

intended purpose and from incorrect behavior.

The following is prohibited:

Figure 5

Climbing onto or riding on the scissor lift or

the load.

Lifting when there are people in the vehicle.

Lifting/lowering when people or animals are

in the danger zone, in particular below the

lift.

Jerky lifting or lowering. Do not cause the

lift to vibrate.

Throwing objects onto or under the lift.

Lifting a vehicle at the incorrect pick-up

points.

Lifting a load on only one platform of the lift.

Lifting vehicles containing hazardous goods.

Operating outdoors or in workshops at risk

from fire or explosion.

Washing cars on the post lift.

Modifications of any kind

3.6 Internal accident, health and

safety, and environmental information

This operating manual does not include the

operating instructions which need to be drafted

by the user of the scissor lift.

The internal operating instructions regulate

actions within the company for the prevention of

accidents, and risks to health & safety and the

environment.

These also include actions in the case of an

emergency, first aid measures etc.

5

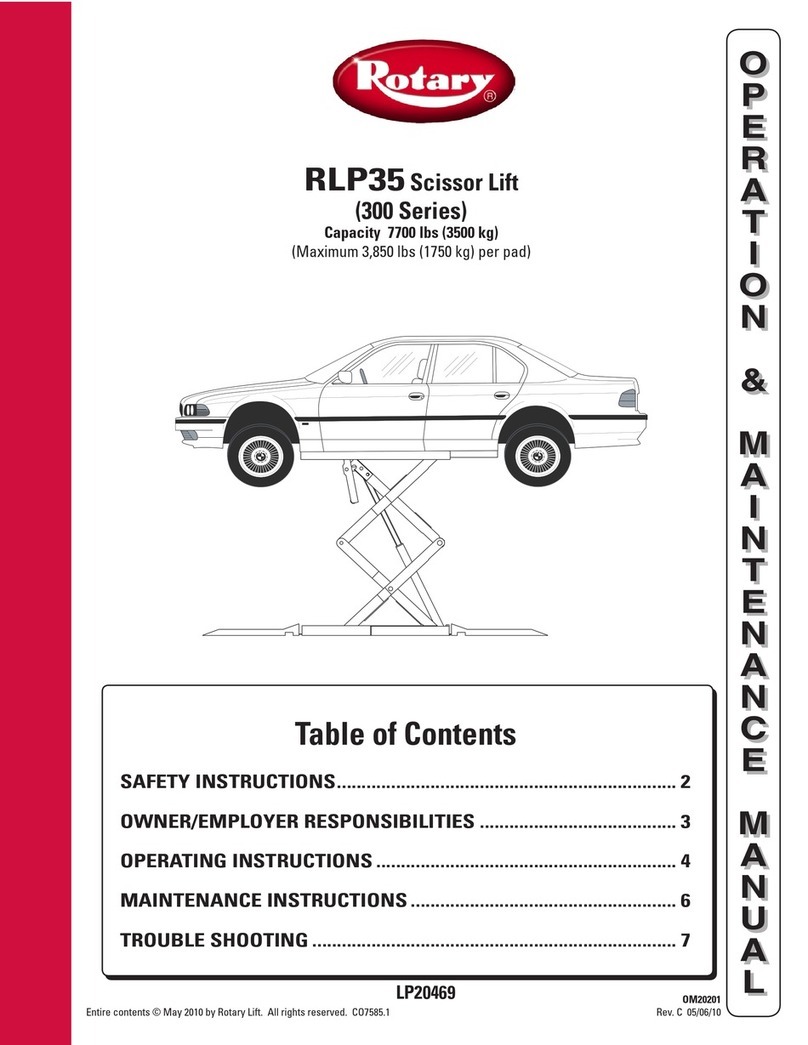

BQ-144

1800

KG

1200

KG

Maximum Axle Load Distribution

No anchors ,prohibited distribution

Heavy

End Light

End