5

Table of Contents

1. Introduction ................................................................7

1.1 About this operating manual ....................................7

1.2 Warning and information symbols ...........................7

1.3 Intended use ...........................................................9

1.4 Incorrect use, incorrect behavior ............................ 9

1.5 Internal accident, health and safety, and environme-

ntal information ........................................ 9

2. Safety ............................... .......................... ..10

2.1 Operators ...............................................................10

2.2 Basic safety requirements ......................................10

2.3 Permitted axle loads and weight distribution .......10

2.4 Ban on unauthorized modications or alterations ....11

2.5 Experts, competent persons ....................................11

2.6 Maintenance contractors, installation staff ...............12

2.7 Safety inspections by competent persons ..............12

2.8 Obligations of the plant operator .............................. 13

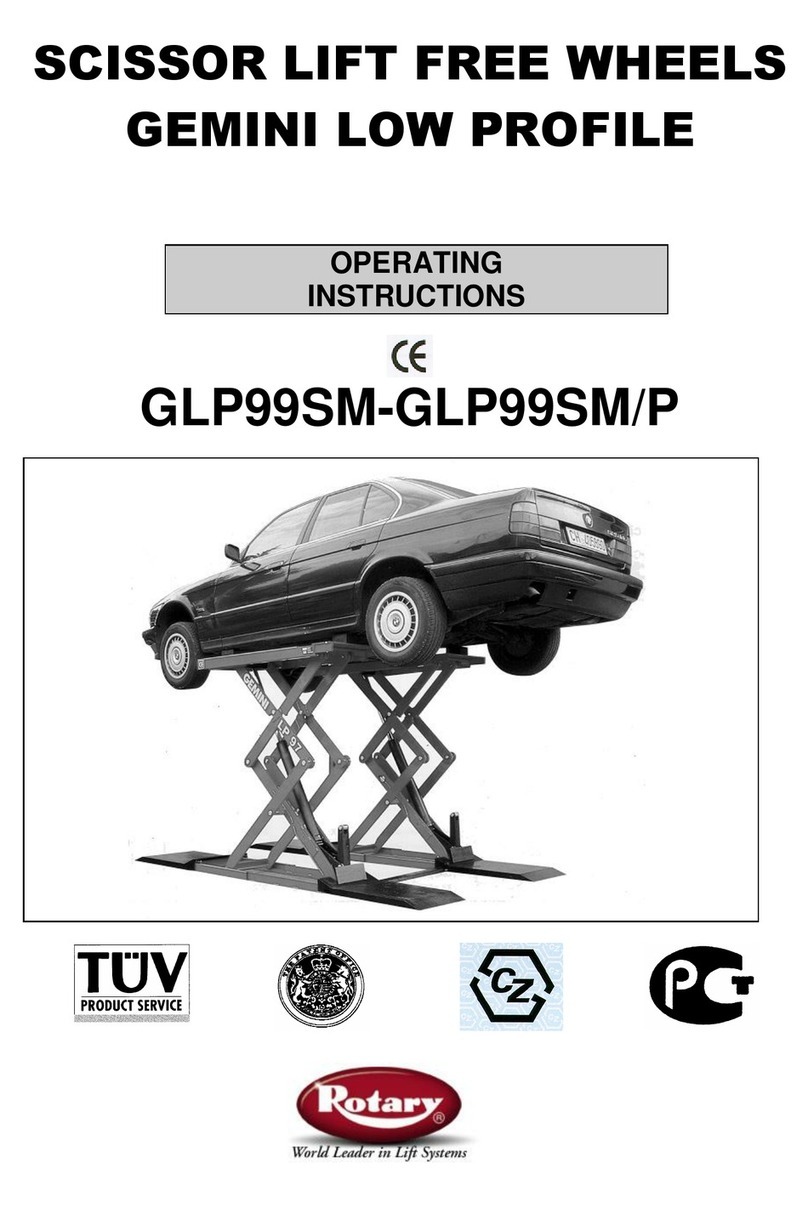

3. The Scissor Lift ...........................................14

3.1 Overview of parts .....................................................14

3.2 General workow .....................................................15

3.3 Work area, danger zones ........................................15

3.4 Safety mechanisms .................................................16

3.5 Control unit ........................................................18

4. Operation .......................................................19

4.1 Before loading ........................................................19

4.2 Loading ..................... .............................................19

4.3 To raise lift................................................................20

4.4 While using lift .........................................................21

4.5 Before lowering lif t..........................................21

4.6 To lower lift...............................................................21

4.7 Unloading ..........................................................21

4.8 Power off ................................................................21

5. Problems, causes, actions............................21

5.1 Troubleshooting by the operator ..............................21

5.2 Troubleshooting by authorized maintenance

contractors ................................................................... ....22

6. Authorized lowering .......................................25

7. Technical data .................................................26

8. Cleaning ...........................................................32

9. Maintenance and repair ..................................31

9.1 Qualication of maintenance and repair staff ...........32

9.2 Maintenance and repair safety regulations ............. .32

9.3 Maintenance work ...........................................33

9.4 Approved hydraulic oils ............................................35

9.5 Check, rell, change the hydraulic oil .......................35

9.6 Repair work (Repairs) ..............................................36

10.Transport, Storage ...................................37

10.1 Transport ................................................................38

10.2 Ofoading.................................................................38

10.3 Storage ....................................................................38

11.Assembly ........................................................39

11.1 Assembly safety instructions ................................. 39

11.2 Site specications ...................................................39

11.3 Installation preparations ..........................................39

11.4 General lift location..................................................40

11. 5 Control cabinet connections...................................40

11.6 Oil lling bleeding hose connection.........................43

11.7 Final positing of platforms .................. .................44

11.8 Anchoring................................................................45

11.9 Hose covers and anchoring(surface mounted)......46

11.10 Flush mount pit.....................................................46

11.11 Adjust cushion device...........................................47

12. Commissioning ............................................48

12.1 Check the operation................................ ..............48

12.2 Test the hydraulic system.. ....................................48