ROXELL - 004 - 4215OPTIMAX - TABLE OF CONTENTS

TABLE OF CONTENTS

CONTENTS

GENERAL INFORMATION

PART I : INSTRUCTIONS FOR THE USER

GENERAL SAFETY RULES I-3.......................................................

DIRECTIONS FOR OPERATING THE SYSTEM I-4.....................................

- PUTTING THE SYSTEM INTO USE I-4..........................................................

- PRACTICAL DATA FOR USING THE SYSTEM. I-4................................................

- PROGRAMMED FEEDING I-5..................................................................

- USE OF OPTIMAX AND OPTIMAX STARTPAN I-5................................................

- DIRECTIONS FOR USE OF THE ANTIPERCH WIRE I-5............................................

-WHENSTARTINGANEWFLOCK: I-6..........................................................

MAINTENANCE I-7.................................................................

MAINTENANCE INSTRUCTIONS I-8.................................................

TROUBLE SHOOTING GUIDE I-9/10....................................................

OPERATORS GUIDE I-11/12............................................................

DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

EC-DECLARATION OF CONFORMITY

PART II : COMPONENTS

GENERAL LAY-OUT II-2............................................................

PRODUCT NUMBERS II-3...........................................................

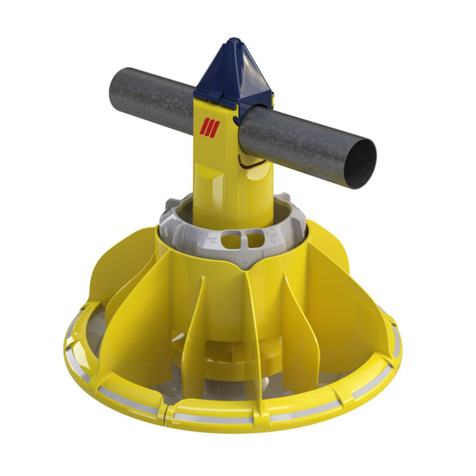

PARTS OPTIMAX PAN II-4...........................................................

OPTION : PAN REMOVER II-4........................................................

SUSPENSION COMPONENTS II-5....................................................

HAND OPERATED CENTRAL WINCH II-6.............................................

MOUNTING PLATE F/HAND OPERATED CENTRAL WINCH II-6.........................

TELESCOPICAL WINCH DRIVE ASSEMBLY II-6.......................................

SINGLE EYE PULLEY II-7............................................................

HEAVY DUTY PULLEY II-7...........................................................

FEEDER LINE COMPONENTS II-8....................................................

OPTION : AUGER INJECTOR KIT II-8.................................................

MOTOR II-9........................................................................

WINCH W/SWITCH + CP - MOTOR OPERATED II-9....................................

STANDARD : CONTROL SWITCH FOR WINCH II-9.....................................

WINCH W/SWITCH - MOTOR OPERATED II-10.........................................

OPTION : CONTROL PANEL FOR CENTRAL WINCH II-10................................

OPTION: CONTROL SWITCH FOR WINCH II-10.........................................

FEED INTAKE BOOT II-11............................................................

POULTRY INTAKE BOOT WITH SENSOR (OPTION) II-12................................

CANNON BALL (OPTION) II-13........................................................

THUMPER ASSEMBLY (OPTION) II-13.................................................

OPTION : DOUBLE FEED INTAKE BOOT II-13..........................................

THUMPER KIT FOR DOUBLE INTAKE BOOT(OPTION) II-14..............................

DOUBLE POULTRY INTAKE BOOT W/SENSOR (OPTION) II-14...........................

COVER HALF FOR 100KG HOPPER II-15..............................................

100KG HOPPER II-15.................................................................

STRAINER FOR 100KG HOPPER II-16.................................................

HOPPER EXTENSION 50KG II-16.....................................................

PARTS FOR ADJUSTING THE FEED LEVEL TUBES II-16................................

WINCH KIT II-16.....................................................................

POWER UNIT II-17...................................................................

CONTROL UNIT WITHOUT PAN II-18/19..................................................

CONTROL UNIT OPTIMAX WITHOUT PAN II-20/21.........................................

OPTION : INTERMEDIATE CONTROL UNIT WITHOUT PAN II-22/23..........................

OPTION : CONTROL UNIT WITH SENSOR - WITHOUT PAN II-24/25.........................