ROXELL - 0516

GENERAL INFORMATION

THESE INSTRUCTIONS MUST BE READ, UNDERSTOOD AND ALL POINTS OBSERVED BY THE

USER, THE RESPONSIBLE AND OPERATING PERSONNEL.

1. OBEY THE LEGAL REGULATIONS AND THE APPLICABLE RULES!

This concerns, among other things, the European directives transposed into national legislation and/or the laws,

safety and accident prevention regulations that apply in the user's country.

Duringassembly,operationandmaintenanceoftheinstallation the legalregulationsconcernedandthe applicable

technical rules must be obeyed.

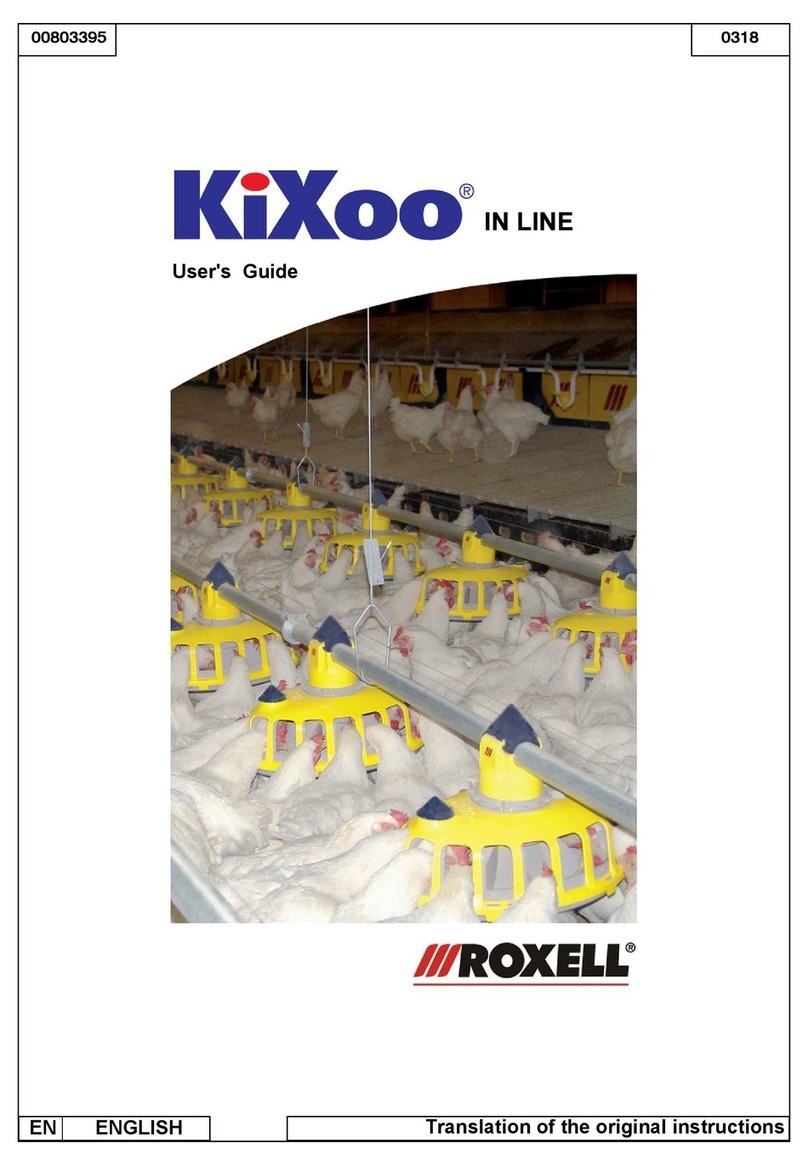

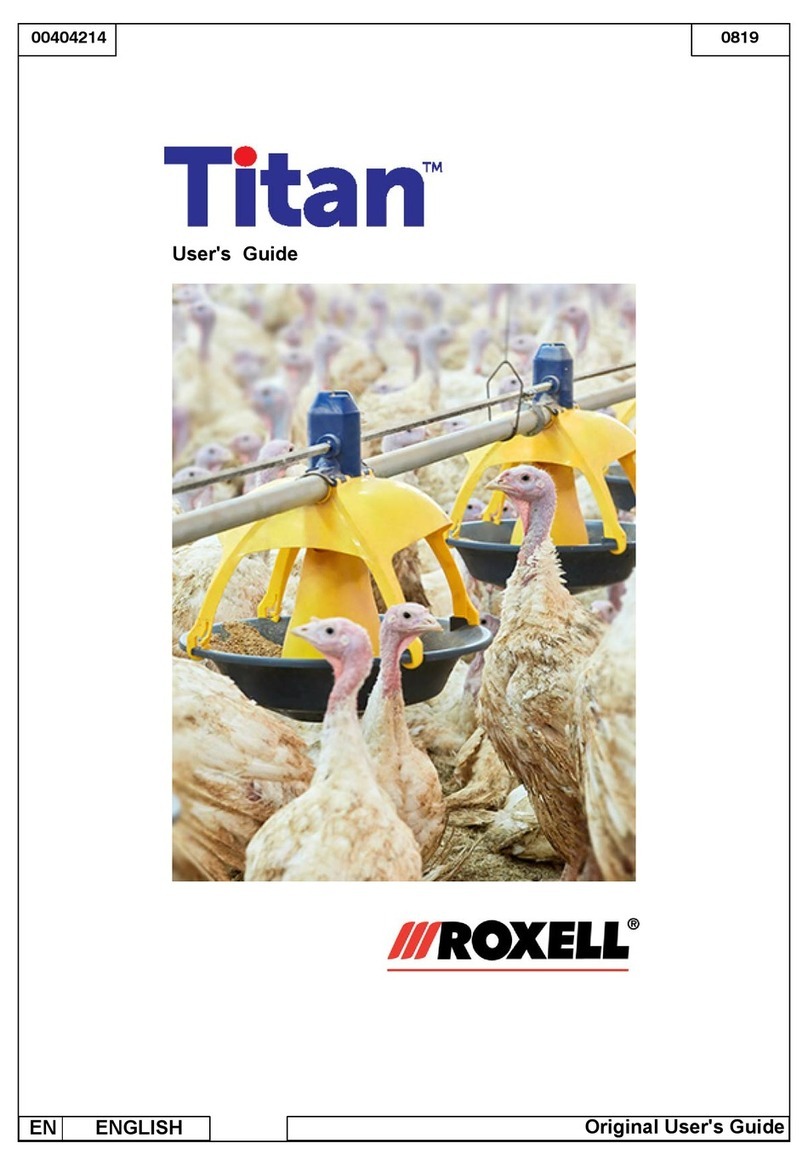

2. INTENDED USE

The installation has been designedsolely for intensive livestock use and has been developed accordingto the ap-

plicablerulesofgoodworkmanship.Extraloadingoftheproductisthereforeprohibited.Anyotheruseisconsidered

to be improper use. The manufacturer is not responsible for damage resulting there from. The user bears sole re-

sponsibility.

3. NOT-INTENDED USE

All use different than described in point 2” intended use” is at the responsibility of the end user.

4. LIABILITY

The (Extended) Warranty will not apply if any of the following has occurred: failure to conduct incoming goods

inspection with regards to the Products, improper handling, transportation, modification or repair; accident, abuse

or improper use; improper assembly, installation, connection or maintenance (having regard to Roxell’s most

current assembly, installation, connection and maintenance manuals); force majeure; negligence, lack of

supervision or of maintenance on the part of customer; normal wear and tear; use of cleansing agents and

disinfectantsthatareexcludedinRoxell’smostcurrentuseandmaintenancemanuals;useofcleansingagentsand

disinfectants in violation with the instructions received from the suppliers; or use of the Products in an ATEX-

surrounding.

The(Extended) Warrantyshallnotapplyintheeventofadefectcausedeitherbymaterialsoraccessoriessupplied

byorservices renderedby Customer;orbyan interventionbya personorentitywhichisnotauthorisedor qualified

forcarryingoutsuch intervention.Furthermore,the(Extended)Warrantywill onlyapplyiftheProductsare usedin

livestock houses and if all parts or components of the Products are supplied by Roxell.

Roxell will not be liable for any damages caused due to improper use, assembly, installation, connection or

maintenance of the Products. In this respect, the Customer expressly acknowledges that (i) all use, assembly,

installation, connection or maintenance must be donein accordance with Roxell’s most current assembly,

installation, connection and maintenance manuals and (ii) the electrical installation on which the Products must be

connectedmustbe doneinaccordancewithapplicablelocal legislationonelectricalinstallations.Furthermore,the

Products must be tested both mechanically and electrically in accordance with state of the art techniques and

applicable local legislation.

5. PERSONNEL QUALIFICATIONS

USER:

Thepersonwhousesafunctionoroperationofaproductfortheirworkor whoworks ontheproduct.Theusermust

be able to read the instructions for use and fully understand them. The user has knowledge of the functioning and

construction of the installation.

TECHNICALLY TRAINED PERSON:

An expert who can assemble and maintain the installation (mechanically/electrically), and resolve malfunctions.

Onthebasisofhis/hertechnicaltrainingandexperience,he/shehassufficientknowledgetobeabletoassessactiv-

ities, recognise possible dangers and rectify dangerous situations.