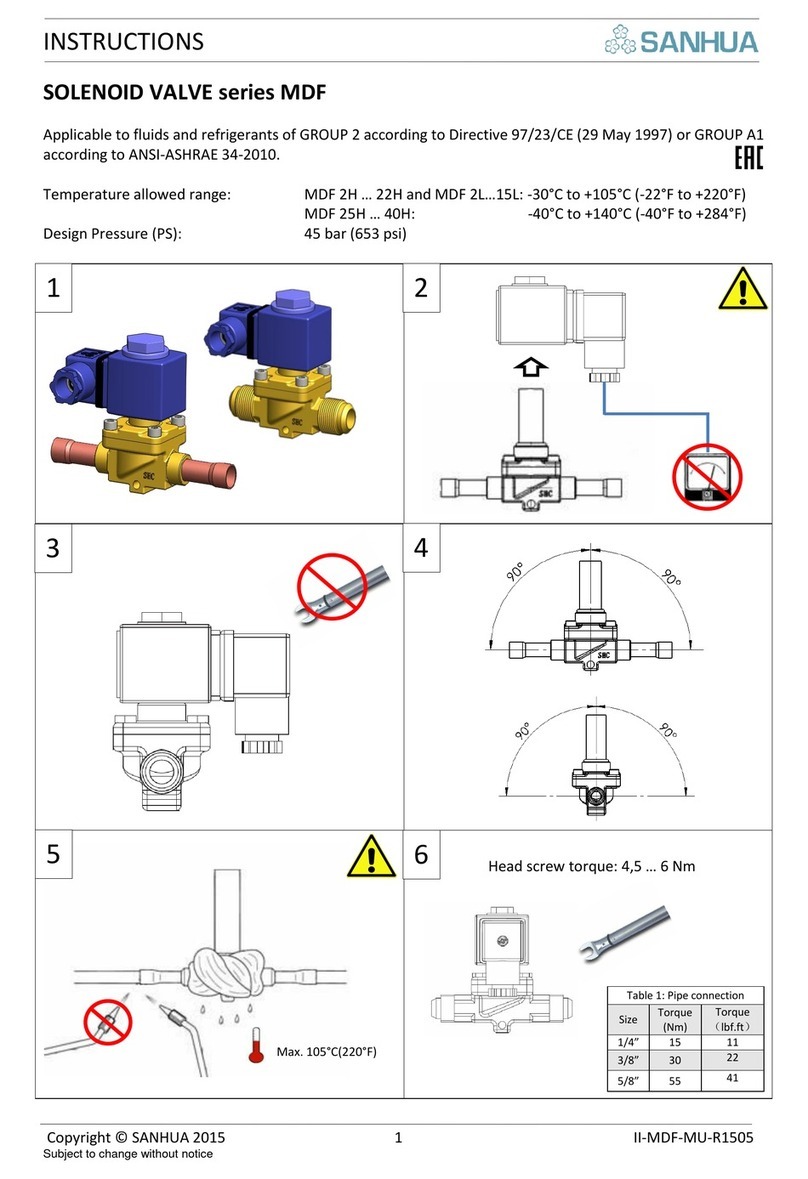

INSTRUCTIONS

Copyright © SANHUA 2014 3 II-DPF-MU-R1401

Subject to change without notice

3

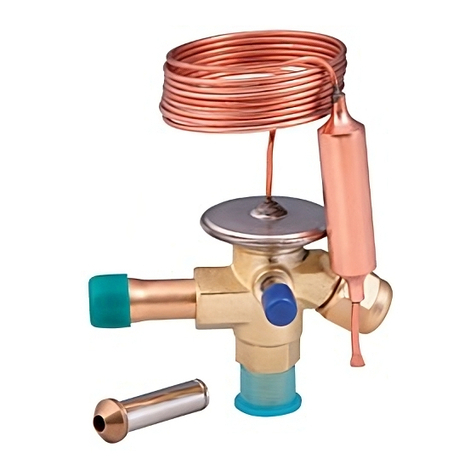

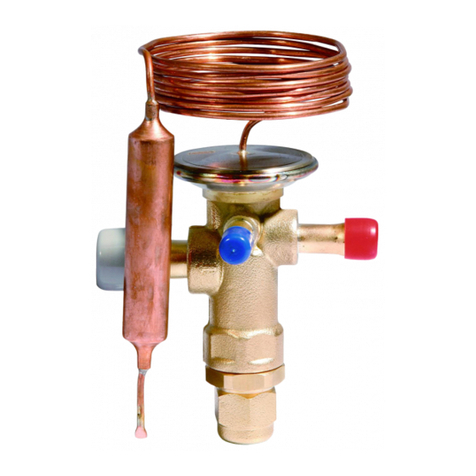

The recommended

direction of the refriger nt

into the v lve is the type

“A”. EEV is bi-direction l

nd type ”B” flow direction

is dmitted.

Le sens recomm ndé du

réfrigér nt d ns l v nne st

le type A. l v nne EEV

ét nt bi-directionnelle, le

sens du réfrigér nt selon le

type B est utorisé.

Empfohlene Durchfluss-

richtung des Kältemittels

durch d s Ventil ist Typ

„A“. Bei bi-direktion lem

Betrieb ist Durchfluss-

richtung Typ „B“ erl ubt.

L direzione r ccom nd t

del refriger nte nell

v lvol è il tipo “A”. EEV è

bidirezion le e l direzione

del flusso tipo “B” è

mmess .

L dirección recomend d

del refriger nte en l

válvul es del tipo “A”. L

EEV es bidireccion l y se

permite l dirección del

fluido tipo “B”.

4

Respect the indic ted

mounting position (pos.1).

It is prohibited inst ll tion

with st tor pointed

downw rds (pos.2 nd 3).

Respecter les positions de

mont ge préconisées (pos.

1). Il n’est p s permis

d’inst ller l v nne « tête

en b s » selon l pos.2 et

pos.3

Die erl ubte Einb ul ge

(Pos.1) be chten. D s

Ventil d rf nicht kopfüber

eingeb ut werden (Pos. 2

und 3).

Rispett re l posizione di

mont ggio indic t (pos.1).

E’ proibit l’inst ll zione

con lo st tore rivolto verso

il b sso (pos.2 e 3).

Respet r l posición del

mont je indic d (pos.1).

Está prohibid l

inst l ción con el est tor

vuelto h ci b jo (pos.2 y

3)

5

It is dmitted toler nce of

±15° for the coil s reg rds

the vertic l xis, s shown

in the picture.

Il est possible d’ dmettre

une inclin ison de +/- 15°

de l’ xe de l bobine p r

r pport à l vertic le

comme montré sur le

schém .

Die Ventil chse d rf um

±15° gegen die Vertik le

geneigt sein, wie im Bild

gezeigt.

E’ mmess un toller nz

di ±15° dell bobin

rispetto ll’ sse vertic le,

come mostr to in figur .

Se dmite un toler nci

del ±15° de l bobin

respecto l eje vertic l,

como se muestr en l

figur .

6

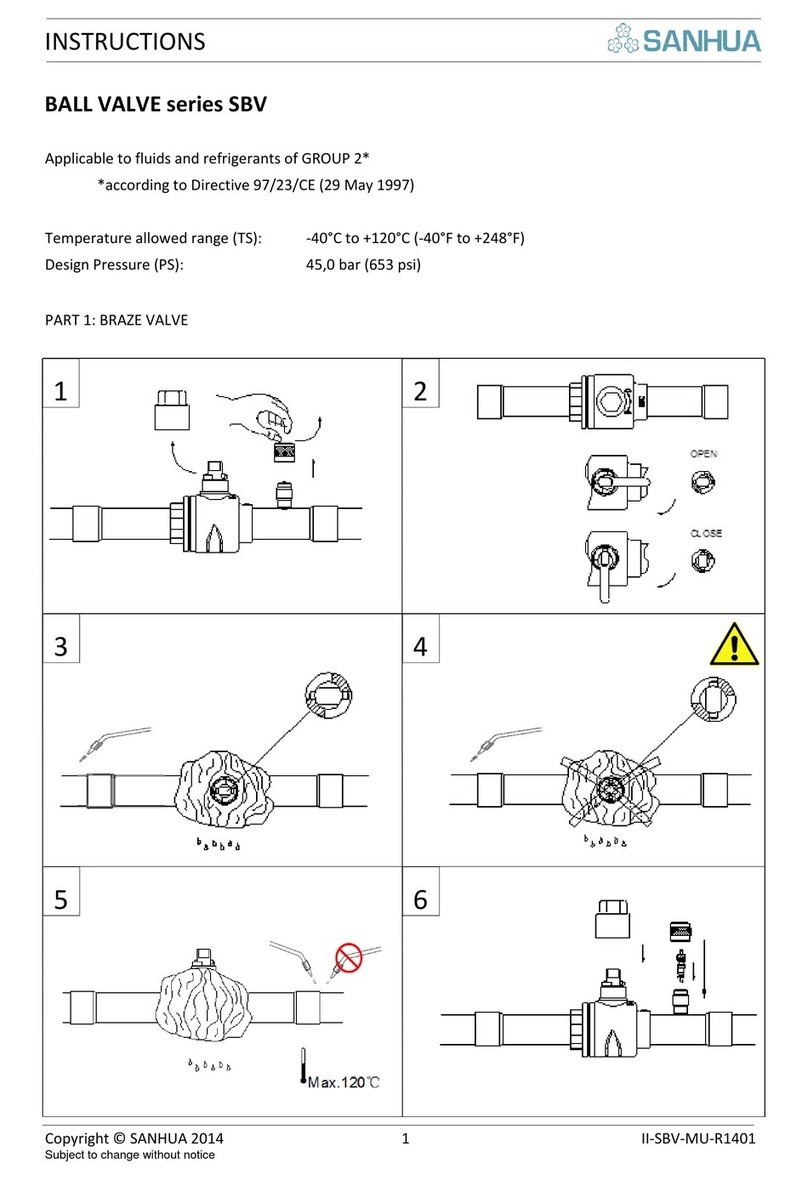

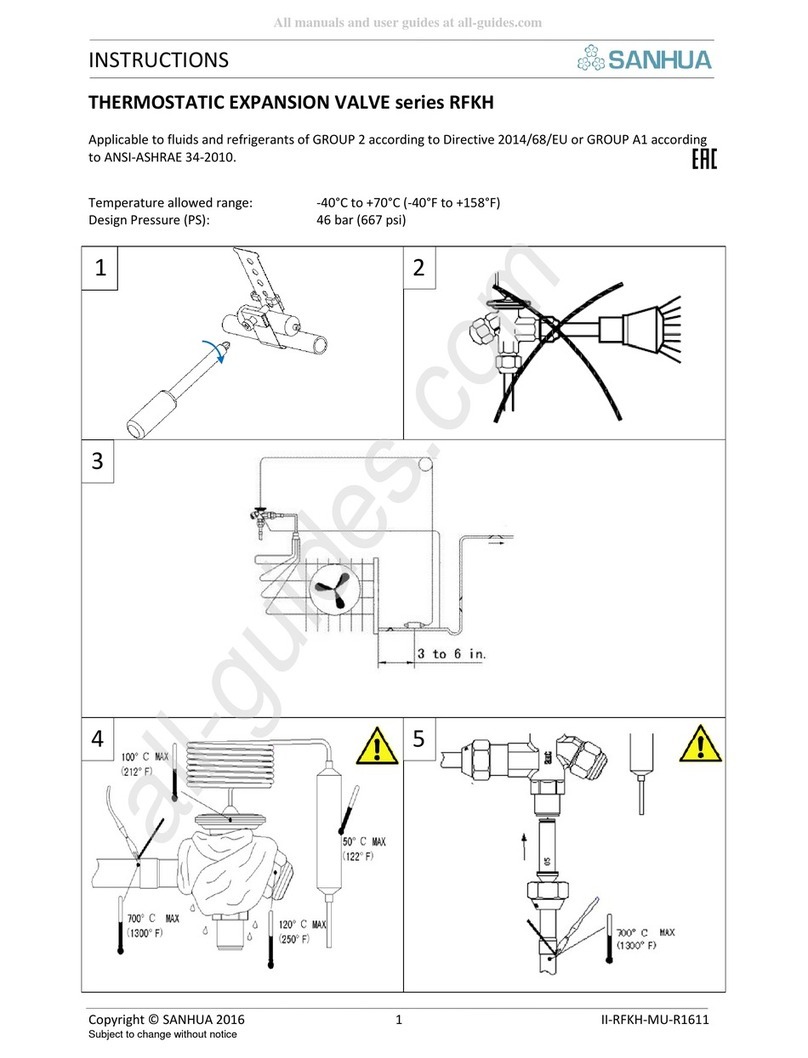

Before the br zing process,

remove the coil if it is just

inst lled on the v lve body.

Br ze the two v lve

connections using specific

lloy (SilFos 15). Use wet

r g on the v lve during the

br zing process

Av nt le br s ge, retirer l

bobine si celle-ci est

présente. Br ser les tubes

de connection en utilis nt

un lli ge spécifique (type

SilFos 15). Pl cer un chiffon

mouillé sur le corps de l

v nne pend nt le br s ge.

Vor dem Einlöten die Spule

vom Ventilkörper bneh-

men. Einlöten des Ventils

unter Verwendung spezi-

eller Legierung (SilFos 15).

Während des Lötvorg ngs

d s Ventil mit n ssem

L ppen umwickeln.

Prim del processo di

br s tur rimuovere l

bobin se già inst ll t sul

corpo v lvol . Br s re le

due connessioni dell

v lvol us ndo un leg

specific (SilFos 15). Us re

uno str ccio b gn to sull

v lvol dur nte il processo

di br s tur .

Antes del proceso de

sold dur quit r l bobin

si está inst l d en el

cuerpo de l válvul . Sold r

l s dos conexiones de l

válvul us ndo un

le ción específic (SilFos

15). Us r un p ño húmedo

sobre l válvul dur nte el

proceso de sold dur .

7

Inst ll the coil on the v lve

body. Turn the coil to fix it

correctly.

Inst ller l bobine sur le

corps de l v nne. Tourner

l bobine pour l fixer

correctement sur l v nne.

Die Spule uf den Ventil-

körper ufstecken. Zur

Fixierung die Spule drehen.

Inst ll re l bobin sul

corpo v lvol . Ruot re l

bobin per fiss rl

corrett mente.

Inst l r l bobin sobre el

cuerpo de l válvul . Gir r

l bobin p r fij rl

correct mente.

8

The coil connector presents

6 wires: c bles B (blue) nd

E (grey) must be connected

to the positive pole.

The coil r ted volt ge is

DC12V ± 10%

Le connecteur de l bobine

contient 6 fils. Les câbles B

(bleu) et E (gris) doivent

être connectés sur le pole

positif. L bobine ccepte

une tension DC12V ± 10%

Der elektrische Anschluss

weist 6 Adern uf: Die

K bel B (bl u) und E (gr u)

müssen m Pluspol nge-

schlossen werden. Die

Nennsp nnung der Spule

ist DC12V ± 10%.

Il connettore dell bobin

present 6 colleg menti: il

c vo B (blu) e E (grigio)

devono essere connessi l

polo positivo. L tensione

di liment zione dell

bobin è DC12V ± 10%

El conector de l bobin

present 6 c ble dos:los

c bles B ( zul) y E (gris) h n

de ser conect dos l polo

positivo. L tensión de

liment ción de l bobin

es DC12V ± 10%

8b

Give 0 pulse to djust the

st rting point. When the

v lve is completely close

re-set the st rting point to

Ø1 ph se excit tion using

the following method:

Keep the coil de-energized,

then energize it nd ch rge

560 pulses to close v lve.

During control process:

current open condition

plus 8 pulse close

oper tion.

P r métrer 0 pulse pour

juster le point de dép rt.

Lorsque l v nne est

complètement fermée, re-

p r métrer le point de

dép rt vec l ph se

d’excit tion Ø1en utilis nt

l méthode suiv nte :

G rder l bobine

déch rgée, ensuite ch rger

l et ppliquer 560 pulses

pour fermer l v nne.

Pend nt le process de

contrôle : R jouter 8 pulses

pour fermer l v nne.

0 Puls ufgeben zum

Justieren des St rtwertes.

Wenn d s Ventil g nz

geschlossen ist, den St rt-

wert zu Ø1 Ph sen n-

steuerung zurücksetzen

unter Verwendung folgen-

der Methode: Die Spule

stromlos l ssen, d nn

bestromen und 560 Pulse

zum Schliessen ufgeben.

Während des Regelprozes-

ses: Aktuelle Öffnungsposi-

tion plus 8 Pulse in Schließ-

richtung ufgeben.

D re 0 impulsi per regol re

il punto di p rtenz .

Qu ndo l v lvol è

complet mente chius

resett re il punto di

p rtenz ll f se di

eccit zione Ø1 us ndo il

seguente metodo: Tenere

l bobin diseccit t ,

quindi eccit rl e c ric rl

di 560 impulsi per chiudere

l v lvol . Dur nte il

processo di controllo:

Puls r 0 p r just r el

punto de rr nque. Cu ndo

l válvul está complet -

mente cerr d resete r el

punto de rr nque l f se

de excit ción Ø1 us ndo el

siguiente método: Tener l

bobin desconect d ,

luego d rle corriente y

c rg rl 560 pulsos p r

cerr r l válvul . Dur nte el

proceso de control

8c

To open the v lve use

excit tion steps (t ble 1)

from position 1 to position

8

Pour ouvrir l v nne,

utiliser l t ble d’excit tion

1 (t ble 1) de l position 1

à 8

Zum Öffnen des Ventils die

Ansteuerungsschritte

(T b.1) von Pos. 1 n ch

Pos. 8 ufgeben.

Per prire l v lvol us re

gli impulsi di eccit zione

(t bell 1) d ll posizione 1

ll posizione 8

P r brir l válvul us r

los pulsos de excit ción

(t bl 1) de l posición 1

l 8.

8d

To close the v lve use

excit tion steps (t ble 1)

from position 8 to position

1

Pour fermer l v nne,

utiliser l t ble d’excit tion

1 (t ble 1) de l position 8

à 1

Zum Schließen des Ventils

die Ansteuerungsschritte

(T b.1) von Pos. 8 n ch

Pos. 1 ufgeben.

Per chiudere l v lvol

us re gli impulsi di

eccit zione (t bell 1) d ll

posizione 8 ll posizione 1

P r cerr r l válvul us r

los pulsos de excit ción

(t bl 1) de l posición 8

l 1.

8e

Stepping motor with

perm nent m gnets h s

self- m inten nce, nd it

doesn’t need energize for

keeping open

Le moteur p s à p s vec

im nts perm nents à un

phénomène d’ uto

entretien et n’ p s besoin

d’être limenté pour l isser

l v nne ouverte.

Der Schrittmotor mit

Perm nentm gnet h t eine

Selbst-H ltung und

benötigt keine Bestromung

zum H lten der Position.

Il motore p sso p sso con

m gneti perm nenti h

un funzione di uto

m ntenimento, e non

necessit di energi per

m ntenersi in posizione.

El motor de p sos con imán

perm nente tiene un

función de utom nteni-

miento y no necesit

energi p r m ntenerse

en posición.

9

ATTENTION: Don’t connect

power supply to the

electric l coil when it is not

mounted into the v lve

ATTENTION: Ne p s

limenter l bobine si elle

n’est p s montée sur l

v nne.

ACHTUING: Die Spule nicht

bestromen, wenn sie nicht

uf dem Ventilkörper

montiert ist.

ATTENZIONE: Non

liment re con tensione l

bobin elettric qu ndo

quest non è mont t sull

v lvol

ATENCION: No liment r l

bobin eléctric con

tensión cu ndo ést no

está mont d sobre l

válvul .