INSTRUCTIONS

Copyright ©SANHUA 2015 II-RFGB-MU-R1507

Subject to change without notice

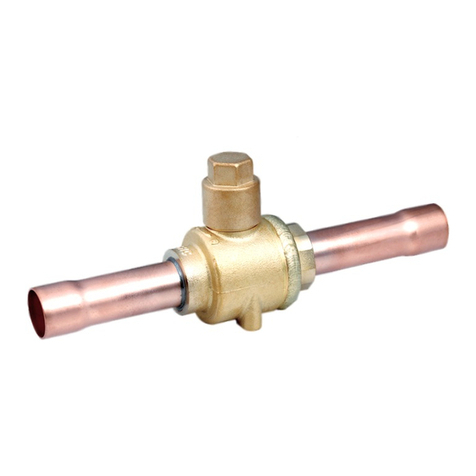

ATTENTION: Install the

valve only in the

systems having

features according with

the information

indicated on valve top

ATTENZIONE: Installare

la valvola solo in

sistemi con

caratteristiche in

accordo alle

informazioni indicate

sulla sommità della

valvola

ВНИМАНИЕ:

Исользуйте ТРВ

только в системах,

соответствующих

характеристикам ТРВ

(указаны на корпусе).

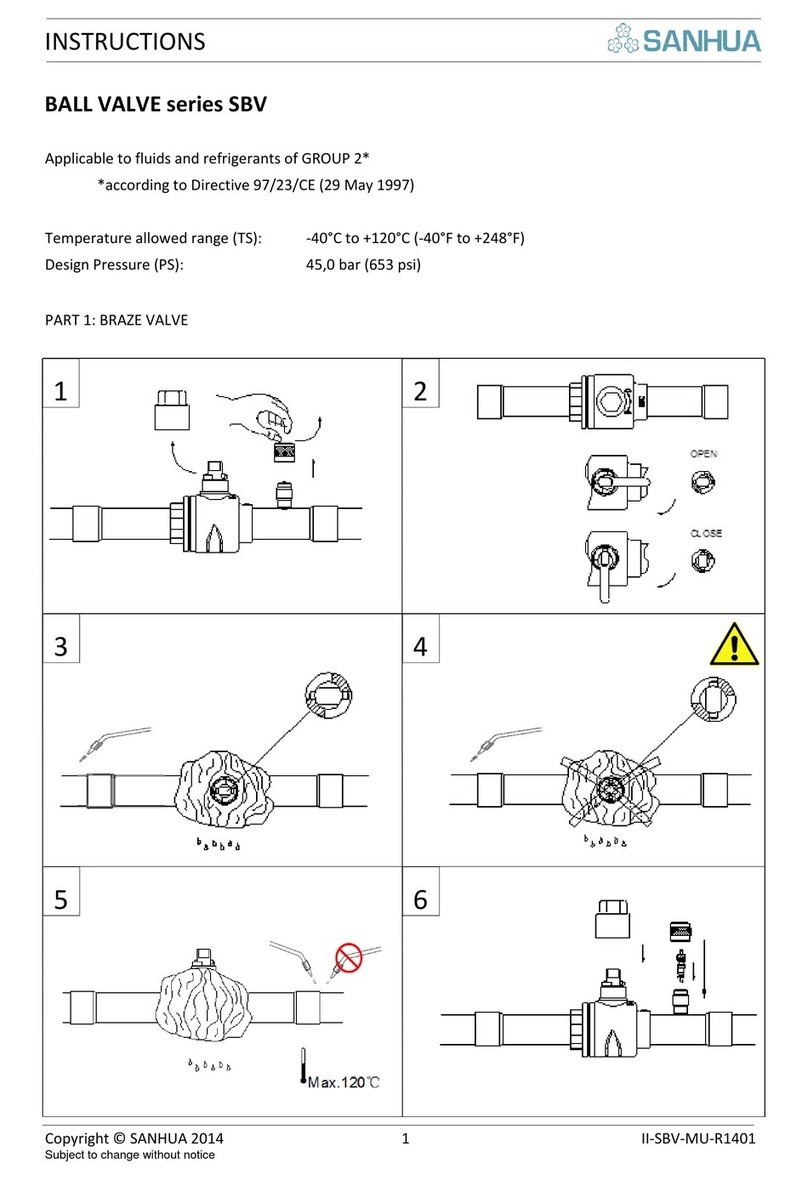

SOLDER VERSION:

Braze inlet, outlet and

(if present) external

equalization

connections of TEV

using specific alloy

(SilFos 15). Use a wet

rag on the valve during

the brazing process

VERSION A BRASER:

Braser les connections

d’entrée, de sortie et (si

présent) d’égalisation

externe en utilisant un

alliage spécifique (type

SilFos 15). Placer un

chiffon mouillé sur le

corps de la vanne

pendant le brasage.

LÖTVERSION:

Eingang, Ausgang

und (falls

vorhanden)

externen Ausgleich

einlöten unter

Verwendung

spezieller Legierung

(SilFos 15). Während

des Lötvorgangs das

Ventil mit nassem

Lappen umwickeln.

VERSIONE A SALDARE:

Brasare le connessioni

di ingresso, uscita e (se

presente) di

equalizzazione usando

una lega specifica

(SilFos 15). Usare uno

straccio bagnato sulla

valvola durante il

processo di brasatura.

VERSION SOLDAR:

Soldar las conexiones

de entrada, salida y (si

presente) de la

igualación usando una

aleación específica

(SilFos 15). Poner un

paño húmedo encima

de la válvula durante el

proceso de soldadura.

При пайке патрубков

(входного, выходного

и, при наличии,

внешнего

выравнивания)

пользуйтесь припоем

(SilFos 15). Защитите

вентиль от перегрева

мокрой ветошью.

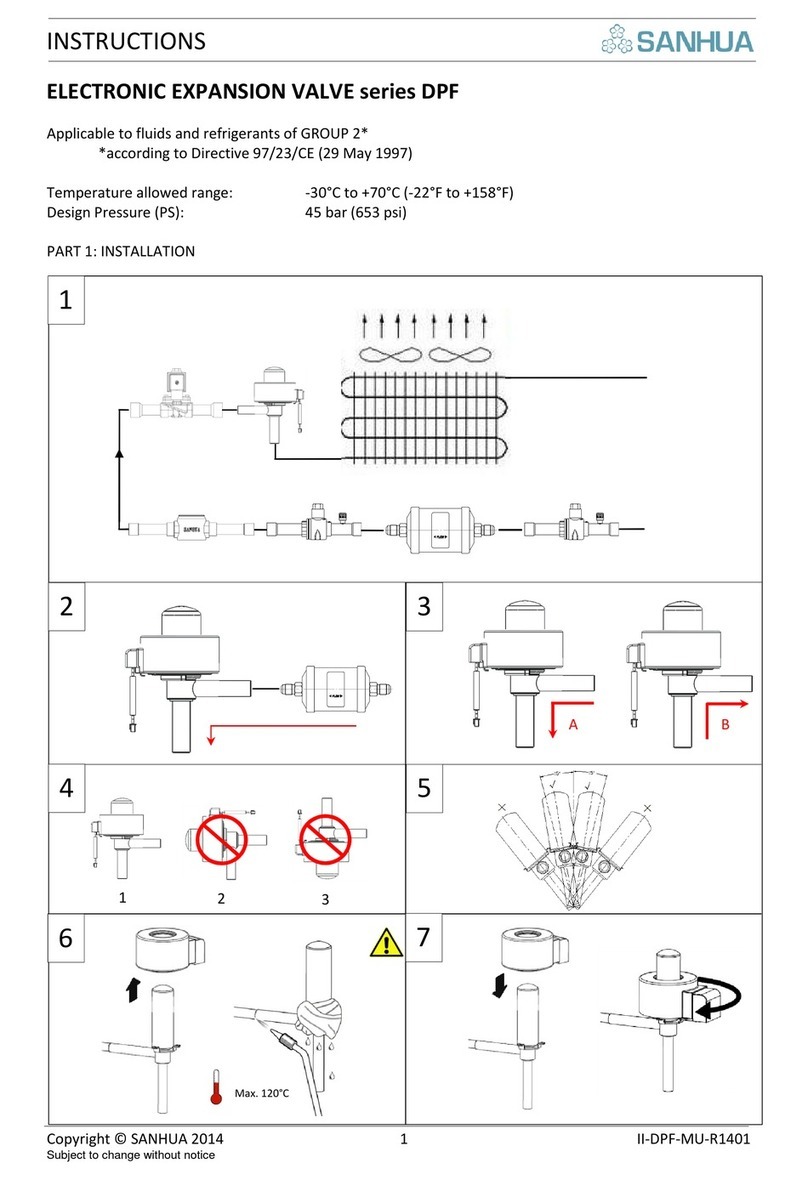

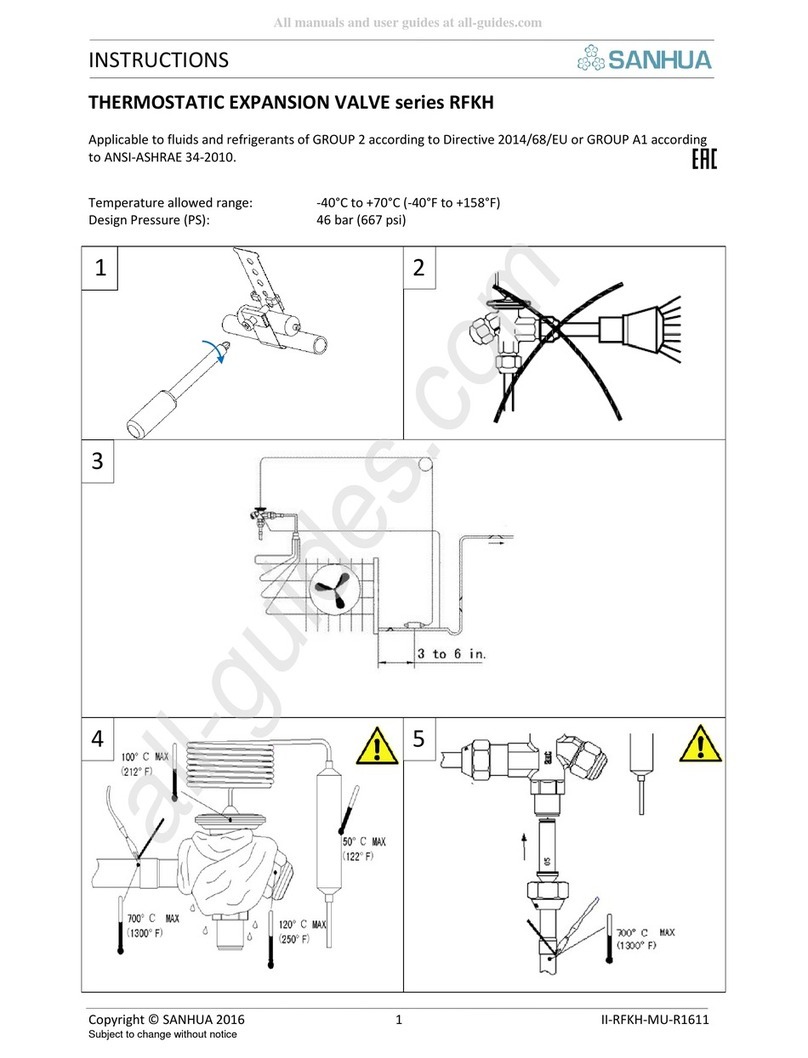

Respect the correct

installing position in

the plant admitted for

the thermostatic

expansion valve (TEV).

Evaporators with liquid

distributors need TEV

with external

equalization

Positionner correctement

la vanne d’expansion

thermostatique dans

l’installation. Les

évaporateurs avec

distributeurs ont besoin

de TEV avec égalisation

externe

Korrekte Einbaulage

des

thermostatischen

Expansionsventiles

(TEV) innerhalb der

Anlage beachten.

Verdampfer mit

Flüssigkeitsverteiler

benötigen TEV mit

externem

Druckausgleich

Rispettare la corretta

posizione di

installazione

nell’impianto ammessa

per la valvola di

espansione

termostatica (TEV). Gli

evaporatori con

distributore di liquido

necessitano di una TEV

con equalizzazione

esterna

Respetar la posición

correcta de instalación

en el equipo admitido

por la válvula de

expansión termostática

(TEV). Los

evaporadores con

distribuidor de líquido

necesitan una TEV con

igualación externa

Выбирайте

правильное

расположение ТРВ в

холодильной

системе. Для

испарителей с

распределителем

жидкости применяйте

ТРВ с внешним

выравниванием.

Install the bulb on the

suction line according

to the position shown

in the picture. Respect

the minimum length L

(vertical distance

between the valve and

the liquid distributor).

It must be L > 7 x D (D=

pipe diameter). Install

the bulb close to the

evaporator (from 3 to 6

in.)

Installer le bulbe sur la

ligne d’aspiration selon la

position indiquée sur le

schéma. Respecter la

distance minimum L

(distance verticale entre

la vanne et le

distributeur). Elle doit

respecter la règle L > 7xD

(où D est le diamètre du

tube cuivre). Installer le

bulbe près de

l’évaporateur (de 3 à 6

pouces)

Thermofühler

gemäß Bild an der

Saugleitung

befestigen.

Minimalen Abstand

L einhalten

(vertikaler Abstand

zwischen Ventil und

Flüssigkeitsverteiler)

. Es muss L > 7 x D

(D=

Rohrdurchmesser)

eingehalten werden.

Den Fühler nahe am

Verdampfer

montieren (von 3 bis

6 in.; von 75 bis

150mm)

Installare il bulbo sulla

linea di aspirazione

secondo la posizione

mostrata in figura.

Rispettare la lunghezza

minima L (distanza

verticale fra la valvola e

il distributore di

liquido). Deve essere

L > 7 x D (D= diametro

del tubo). Installare il

bulbo vicino

all’evaporatore (da 3 a

6 pollici)

Instalar el bulbo en la

línea de aspiración

según la posición

mostrada en la figura.

Respetar la longitud

mínima L (Distancia

vertical entre la válvula

y el distribuidor de

líquido). Debe ser

L>7 x D(D= diámetro)

del tubo). Poner el

tubo cerca de la salida

del evaporador ( de 3 a

6 pulgadas)

Установите

термобаллон на

линию всасывания

как указано на

рисунке, с учетом

минимального

расстояния от ТРВ до

распределителя

жидкости (L > 7 x D,

где D-диаметр

трубки).

Рекомендуемое

расстояние до

испарителя от 3 до 6

дюймов.

Fix the bulb on the

pipe (suction line)

using a clamp as shown

in the picture

Fixer le bulbe sur la ligne

d’aspiration en utilisant

un collier comme montré

sur le schéma

Thermofühler mit

einer Schelle gemäß

Bild am

Saugleitungsrohr

befestigen.

Fissare il bulbo sul tubo

della linea di

aspirazione usando un

morsetto come in

figura

Fijar el bulbo en el

tubo de la línea de

aspiración usando una

abrazadera como en la

figura.

Используя

фиксирующую ленту,

установите

термобаллон на трубу

(линия всасывания)

как указано на

рисунке.

After the TEV

installation, check that:

the evaporator inlet

temperature (t2) must

be bigger than the

evaporator outlet

temperature (t1 =

temperature measured

by the bulb)

Après avoir installé la

vanne, vérifier que la

température d’entrée de

l’évaporateur (t2) est

supérieure à la

température de sortie de

l’évaporateur (t1

mesurée par le bulbe)

Nach Installation des

TEV sicherstellen,

dass die

Verdampfereintrittst

emperatur (t2)

höher ist als die

Verdampferaustritts

temperatur (t1 =

vom Fühler

gemessene

Temperatur).

Dopo l’installazione

della TEV controllare

che: la temperatura di

ingresso

all’evaporatore (t2)

deve essere maggiore

della temperatura di

uscita dall’evaporatore

(t1 = temperatura

misurata dal bulbo)

Después de la

instalación de la TEV,

comprobar que: la

temperatura de la

entrada al evaporador

(t2) ha de ser mayor

que la temperatura de

salida(t1=temperatura

medida por el bulbo).

После установки ТРВ

удостоверьтесь, что

температура

термоголовки (t2)

выше температуры на

выходе из испарителя

(t1=температура

термобаллона).

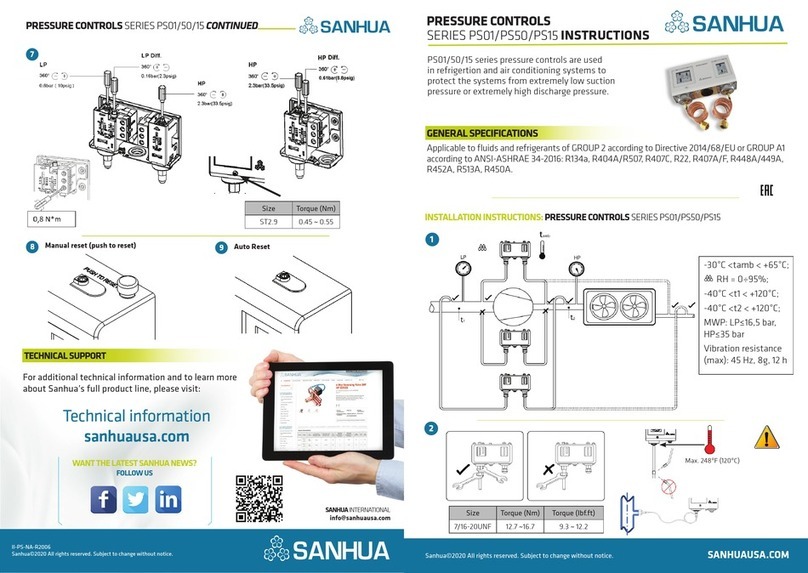

Factory presetting of

TEV (with or without

MOP) is just provided

on standard products.

It is possible to

customize the

superheat value (Tsh

) setting:

Le préréglage d’usine des

TEV (avec ou sans MOP)

est uniquement effectué

sur les composants

standards. Il est possible

de personnaliser la valeur

de désurchauffe (Tsh)

Werkseinstellung

von TEV (mit oder

ohne MOP) wird nur

bei

Standardprodukten

vorgenommen.

Kundenspezifische

Einstellung der

Überhitzung (Tsh)

ist möglich :

Nei prodotti standard è

fornito un pre-

settaggio di fabbrica

della TEV (con o senza

MOP). E’ possibile

personalizzare il

settaggio del

surriscaldamento Tsh:

El producto estándar

de la TEV ( con o sin

MOP) lleva un ajuste

de fábrica. Es posible

personalizar el ajuste

del

supercalentamiento

ТРВ (сМОР ибез

МОР) поставляется с

заводской

настройкой

перегрева. Величину

перегрева (Tsh )

можно изменить:

Using a screwdriver

turn in

A l’aide d’un tournevis,

tourner dans le sens

Mit einem

Schraubendreher die

Usando un cacciavite

girare in senso

Con un destornillador

girar en sentido

Отверткой поверните

регулировочный винт