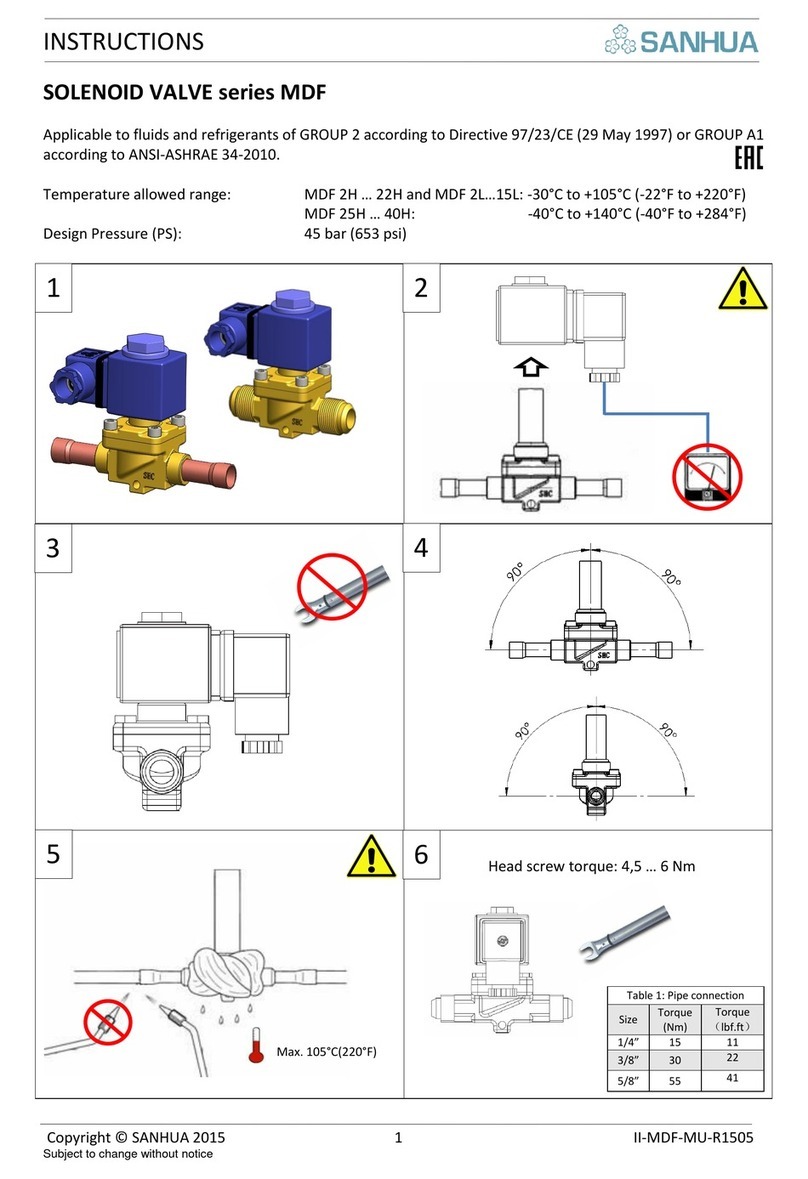

Sanhua MDF Series User manual

Other Sanhua Control Unit manuals

Sanhua

Sanhua RFKA Series User manual

Sanhua

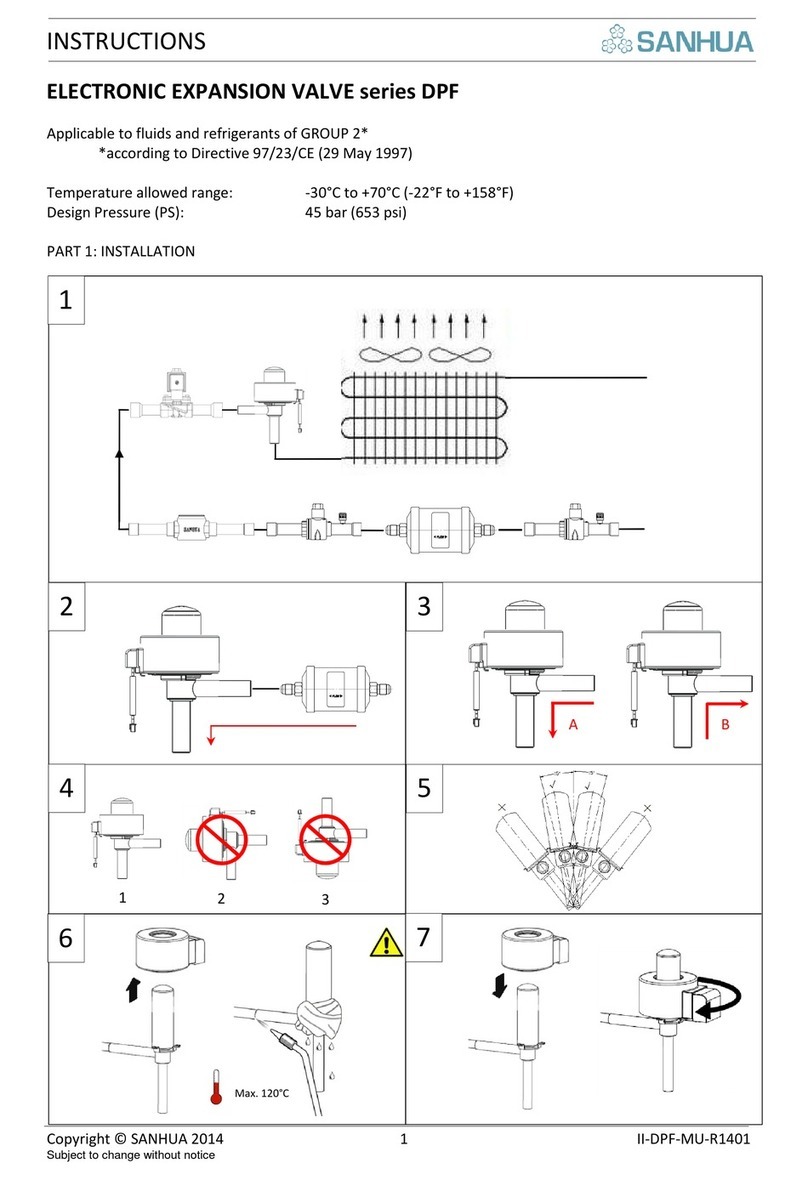

Sanhua DPF-R Series User manual

Sanhua

Sanhua RFKA Series User manual

Sanhua

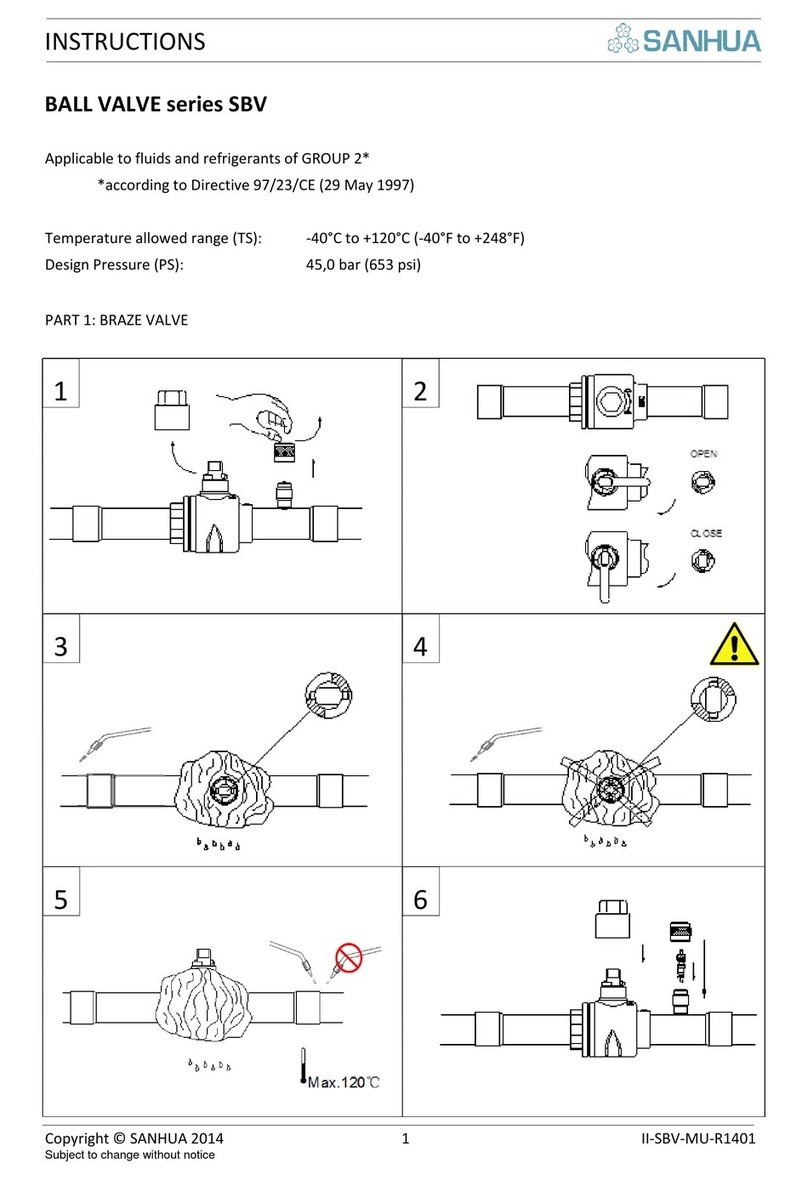

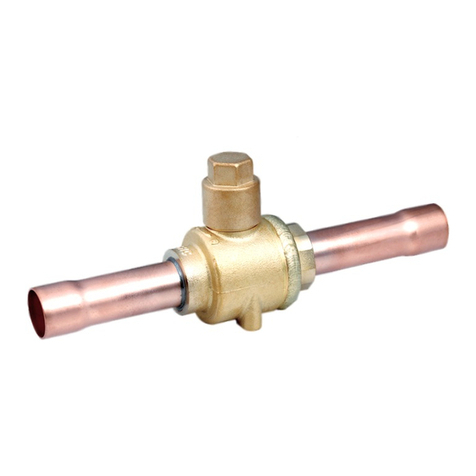

Sanhua SBV Series User manual

Sanhua

Sanhua RFGB Series User manual

Sanhua

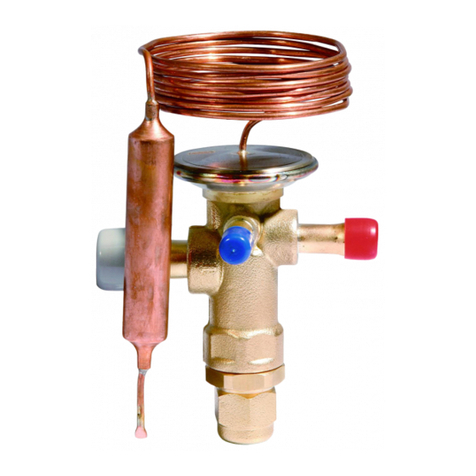

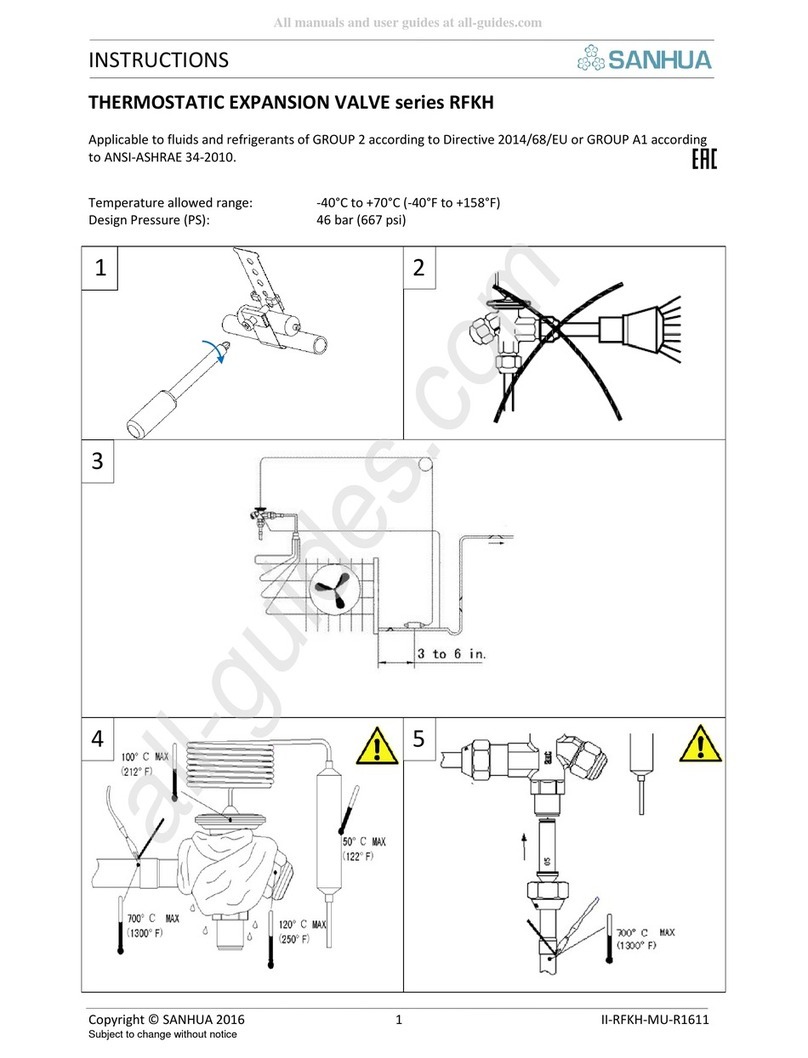

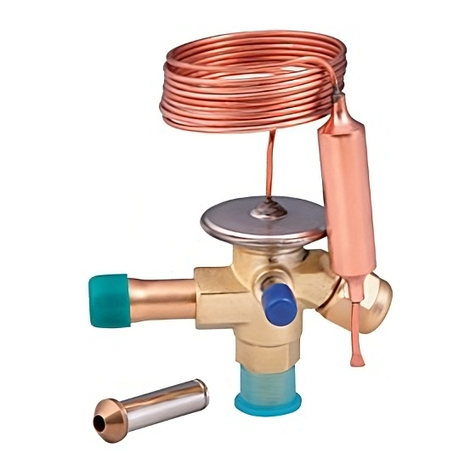

Sanhua RFKH Series User manual

Sanhua

Sanhua RFKA Series User manual

Sanhua

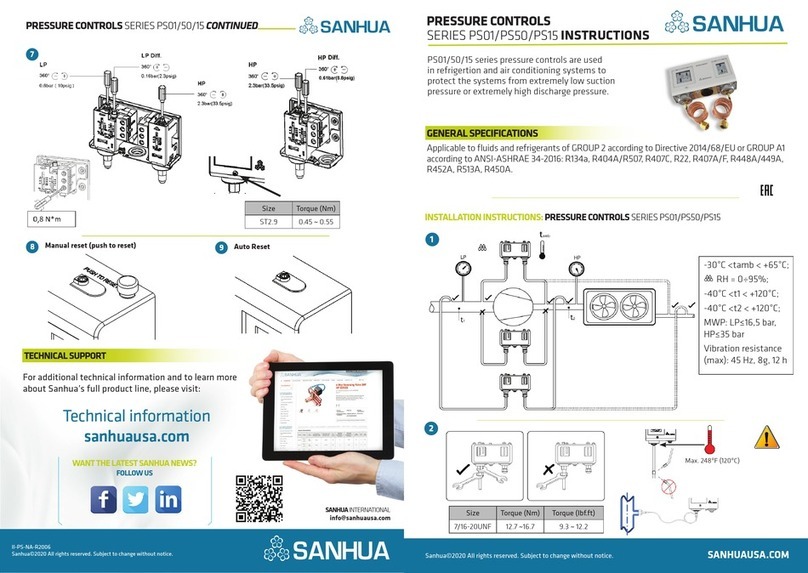

Sanhua PS01 Series User manual

Sanhua

Sanhua RFGB Series User manual

Sanhua

Sanhua RFGD Series User manual

Sanhua

Sanhua RFGD Series User manual

Sanhua

Sanhua RFKH series User manual

Sanhua

Sanhua DPF Series User manual

Sanhua

Sanhua LPF Series User manual

Sanhua

Sanhua RFGB Series User manual

Sanhua

Sanhua MDF Series User manual

Sanhua

Sanhua SBV Series User manual

Sanhua

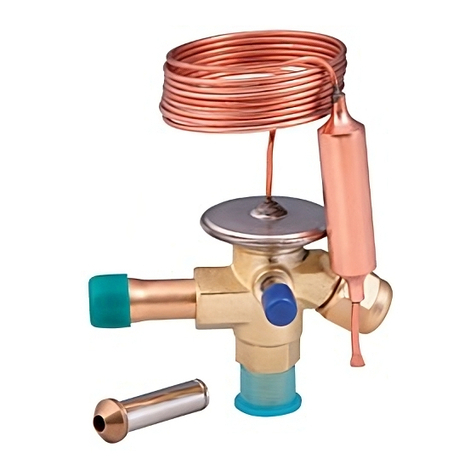

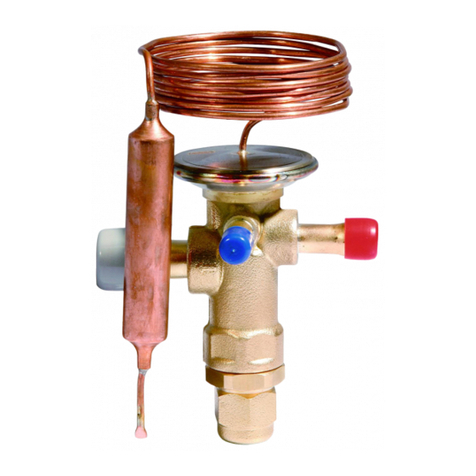

Sanhua TXV Series Manual

Sanhua

Sanhua SBV Series User manual

Sanhua

Sanhua LPF Series User manual