Sanhua©2020 All rights reserved. Subject to change without notice. SANHUAUSA.COM Sanhua©2020 All rights reserved. Subject to change without notice. SANHUAUSA.COM

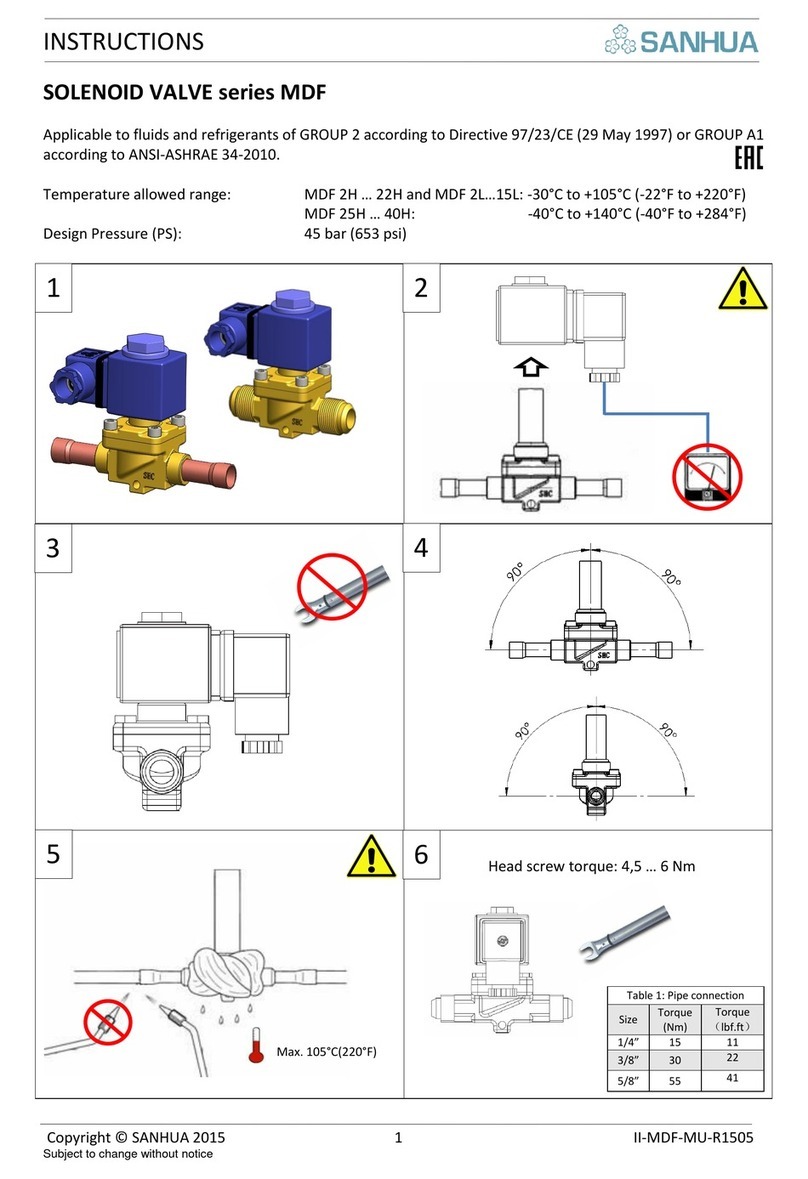

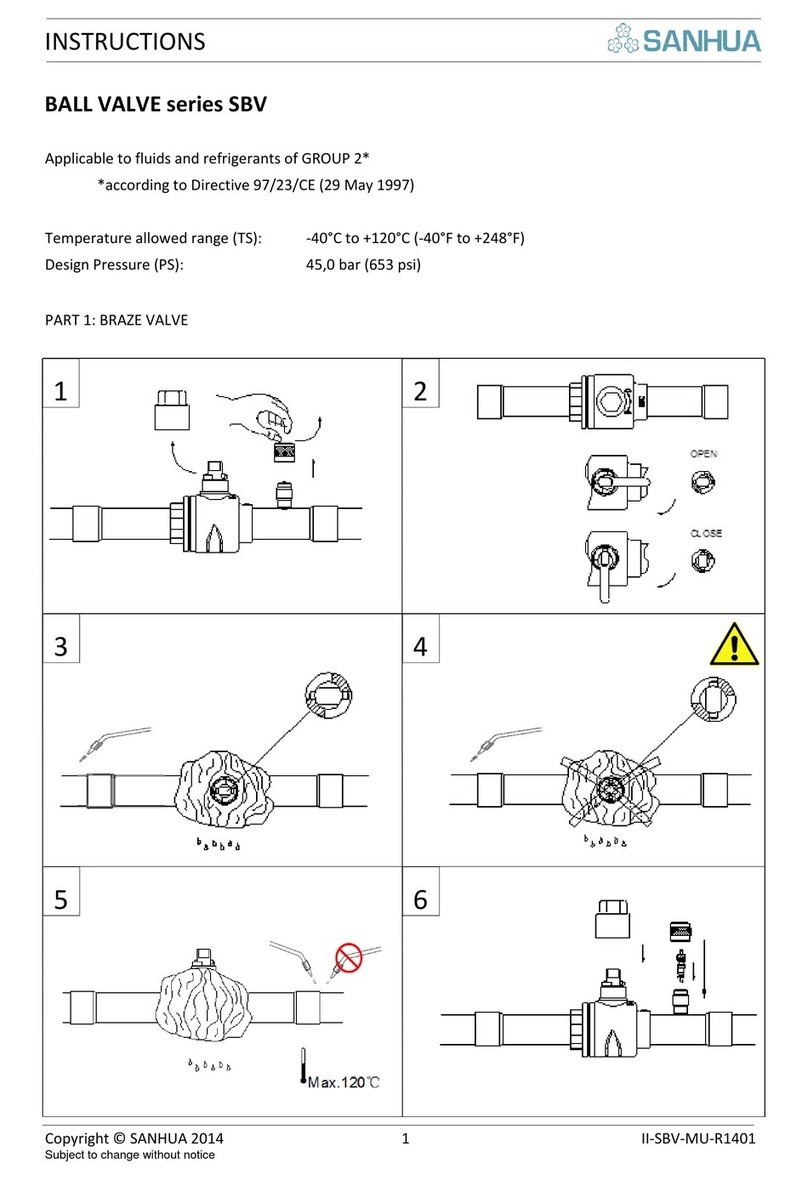

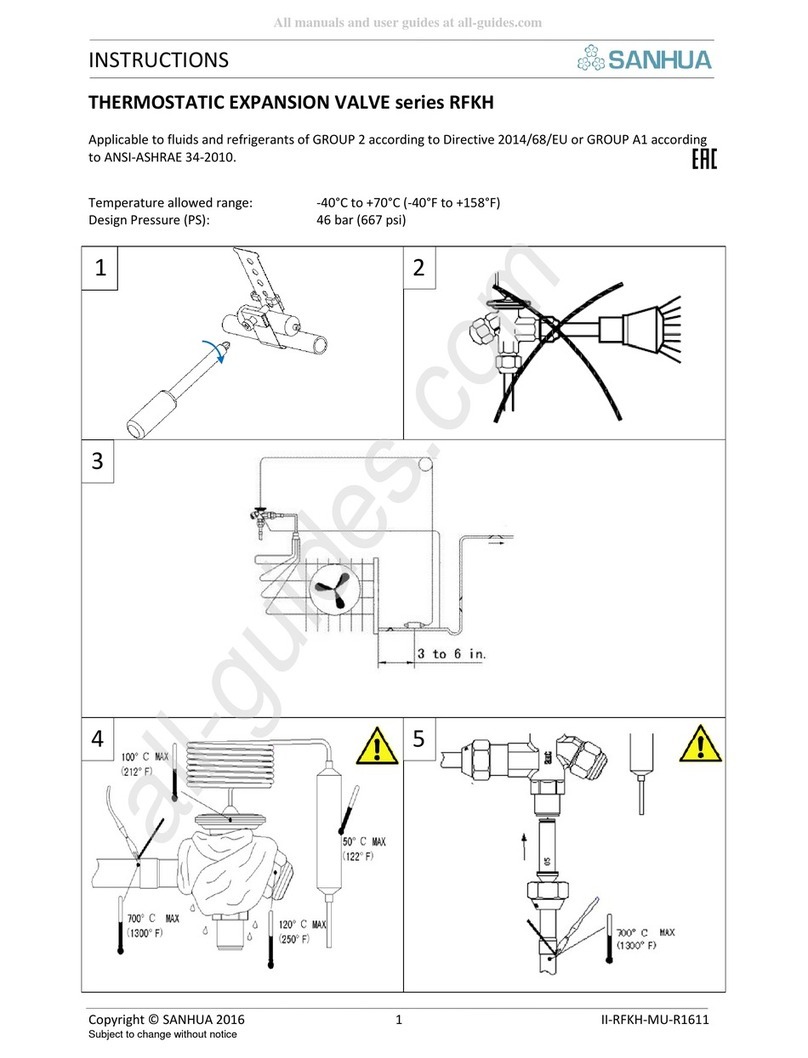

Before the brazing process, remove the coil if it

is just installed on the valve body. Braze the two

valve connections using specific alloy (SilFos 15).

Use a wet rag on the valve during the brazing

process.

EEV SERIES LPF CONTINUED

45

67

8

9

Step Español Français

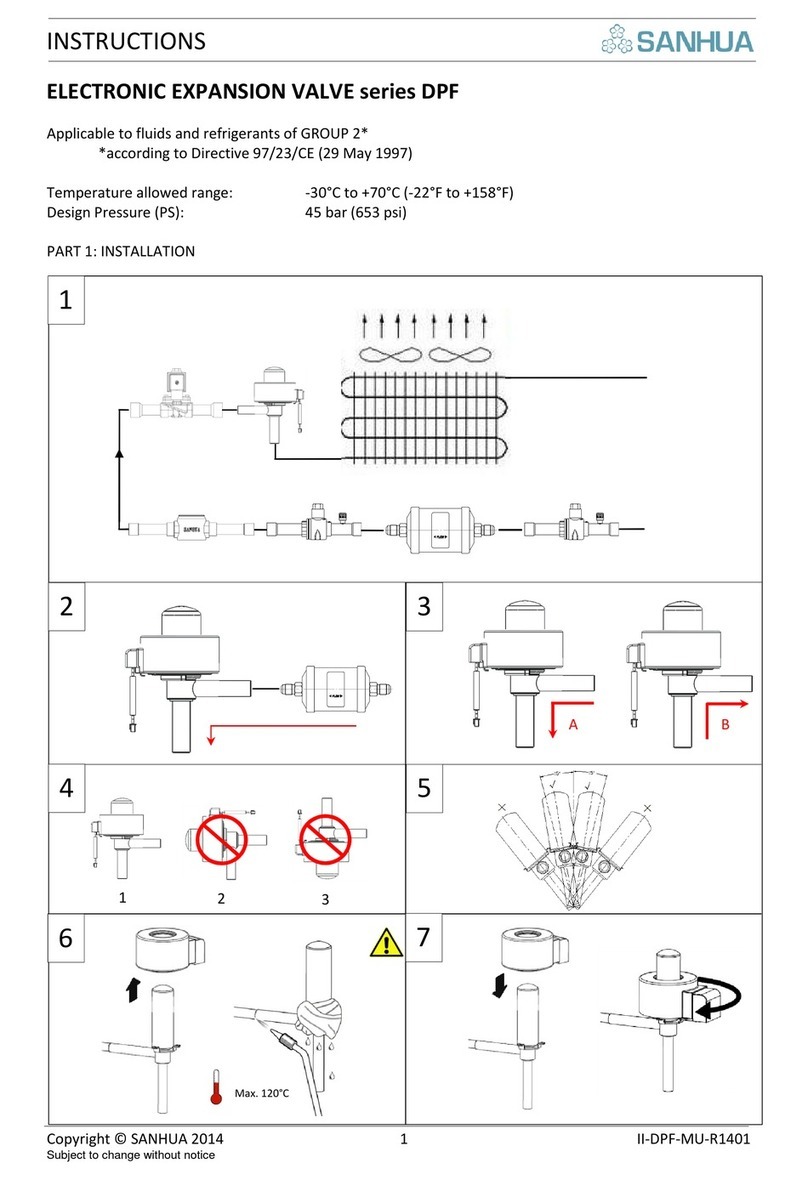

1 Respetar la posición indicada en la instalación

frigorífica para la válvula y para los sensores

que se requieren para el cálculo del sobrere-

calentamiento.

Respecter la position d’installation dans le circuit

frigorifique et utilisez les capteurs adéquats pour

calculer convenablement la surchaue.

2 La dirección de flujo “A” es buena. No fluya en

la dirección “B”. No use esta válvula en bombas

de calor. Instale un filtro deshidratador y un

tamiz de malla 100 antes de la entrada de la

válvula.

Le sens d’écoulement «A» est bon. Ne coule pas dans

le sens «B». N’utilisez pas cette vanne sur les pompes

à chaleur. Installez un filtre déshydrateur et un tamis

de 100 mesh avant l’entrée de la vanne.

3 Respetar la posición del montaje indicada

(pos.1). Está prohibida la instalación con el

estator vuelto hacia abajo (pos.2 y 3)

Respecter les positions de montage préconisées (pos.

1). Il n’est pas permis d’installer la vanne « tête en bas

» selon la pos.2 et pos.3

4 Se admite una tolerancia del ±15° de la bobina

respecto al eje vertical, como se muestra en la

figura.

Il est possible d’admettre une inclinaison de +/- 15°

de l’axe de la bobine par rapport à la verticale comme

montré sur le schéma.

5 Antes del proceso de soldadura quitar la bobina

si está instalada en el cuerpo de la válvula. Sol-

dar las dos conexiones de la válvula usando una

aleación específica (SilFos 15). Usar un paño

húmedo sobre la válvula durante el proceso de

soldadura.

Avant le brasage, retirer la bobine si celle-ci est

présente. Braser les tubes de connection en utilisant

un alliage spécifique (type SilFos 15). Placer un chion

mouillé sur le corps de la vanne pendant le brasage.

6 Al instalar la junta tórica, es necesario asegu-

rarse de que no haya manchas de agua residual

en la junta tórica y la carcasa. Asegurar

que la junta tórica está instalada en su lugar y

encaja con el soporte de la bobina

Avant d’installez le joint o-ring, veuillez ôter toute

présence d’eau ou d’humidité sur l’enveloppe du mo-

teur. Assurez vous qu’une fois installé le joint se place

correctement pour recevoir la bobine.

7 Instalar la bobina sobre el cuerpo de la válvula.

Girar la bobina para fijarla correctamente.

Installer la bobine sur le corps de la vanne. Tourner la

bobine pour la fixer correctement sur la vanne.

8a El conector de la bobina presenta 5 cables: los

cables COM (gris) deben conectarse al polo

positivo.

La tensión nominal de la bobina es DC12V ±

10%.

La bobine possède 5 fils: le fil COM (gris) doit être

connecté au pole positif. La tension d’alimentation de

la bobine est 12VDC± 10%.

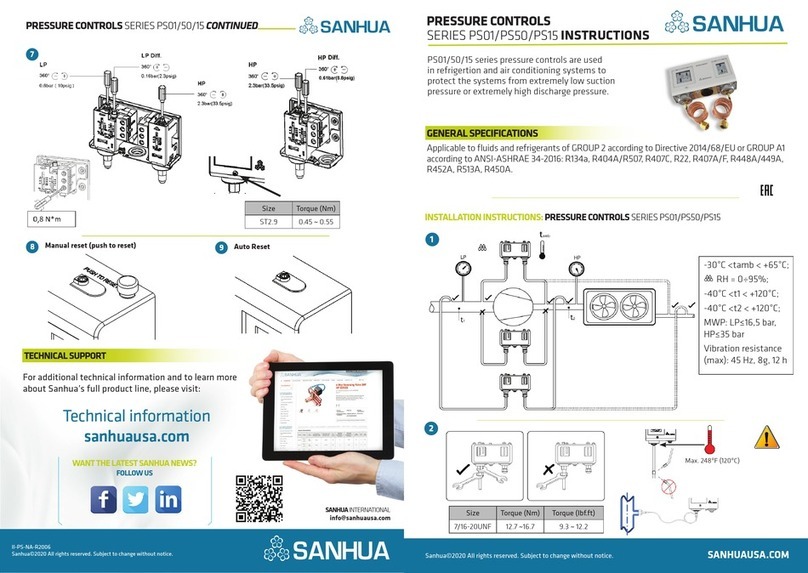

ADDITIONAL LANGUAGES

TABLE 1

Max. 248ºF (120ºC)

0-ring

Install to specified

location

COLOR OF CABLES

A ORANGE

B RED

A YELLOW

B BLACK

COM GREY

CABLE EXCITATION

1 2 3 4 5 6 7 8

A ON ON OFF OFF OFF OFF OFF ON

B OFF ON ON ON OFF OFF OFF OFF

A OFF OFF OFF ON ON ON OFF OFF

B OFF OFF OFF OFF OFF ON ON ON

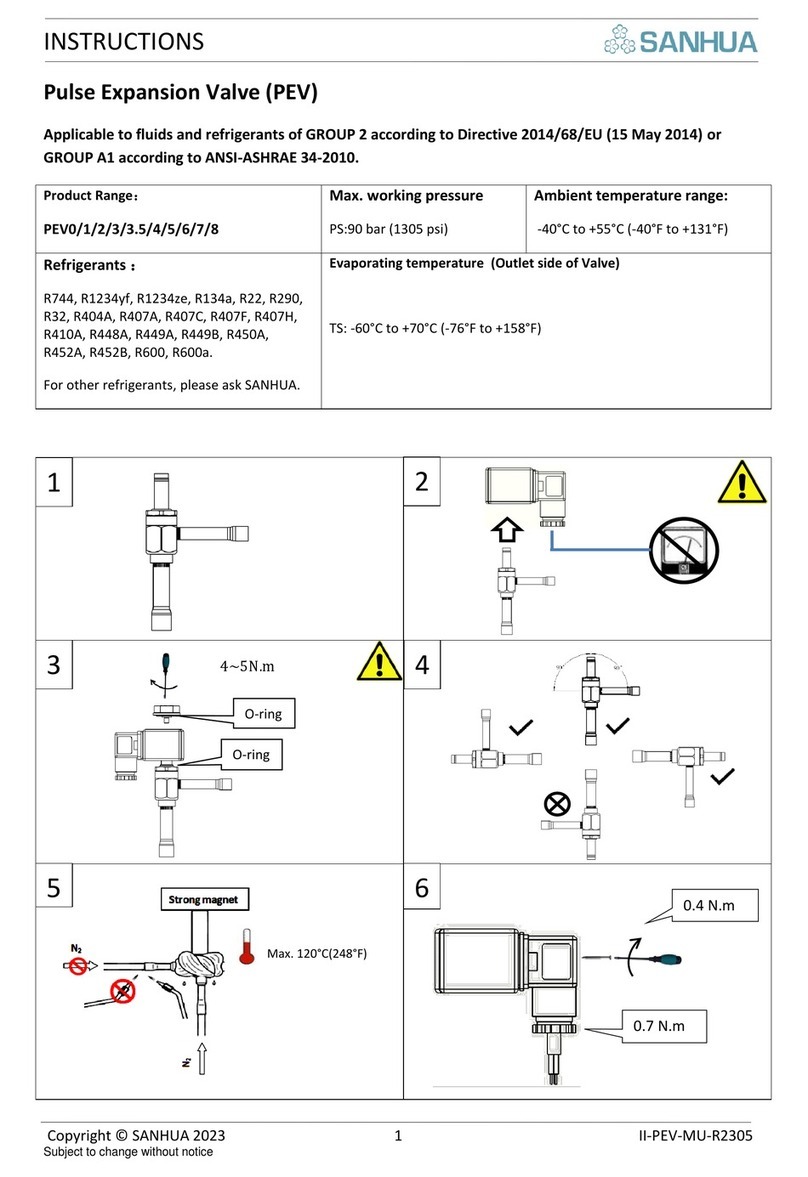

It is admitted a tolerance of ±15° for the coil as

regards the vertical axis, as shown in the picture.

When installing O-ring, it is necessary to ensure

that there is no residual water stain in O-ring and

shell. Ensure that the O-ring is installed in place

and fits with the coil holder.

Install the coil on the valve body. Turn the coil to

fix it correctly.

A. The coil connector presents 5 wires: cables COM ( grey ) must be

connected to the positive pole. The coil rated voltage is DC12V ± 10%.

B. Give 0 pulse to adjust the starting point. When the valve is com-

pletely close re-set the starting point to Ø1 phase excitation using the

following method: Keep the coil de-energized, then energize it and

charge 560 pulses to close valve. During control process: current open

position plus 8 pulse in closing direction.

C. To open the valve use excitation steps (table 1) from position 1 to

position 8.

D. To close the valve use excitation steps (table 1) from position 8 to

position 1.

E. Stepping motor with permanent magnets has self- maintenance,

and it doesn’t need energize for keeping open.

ATTENTION: Don’t connect power

supply to the electrical coil when

it is not mounted into the valve.