4

TECHNICAL DATA

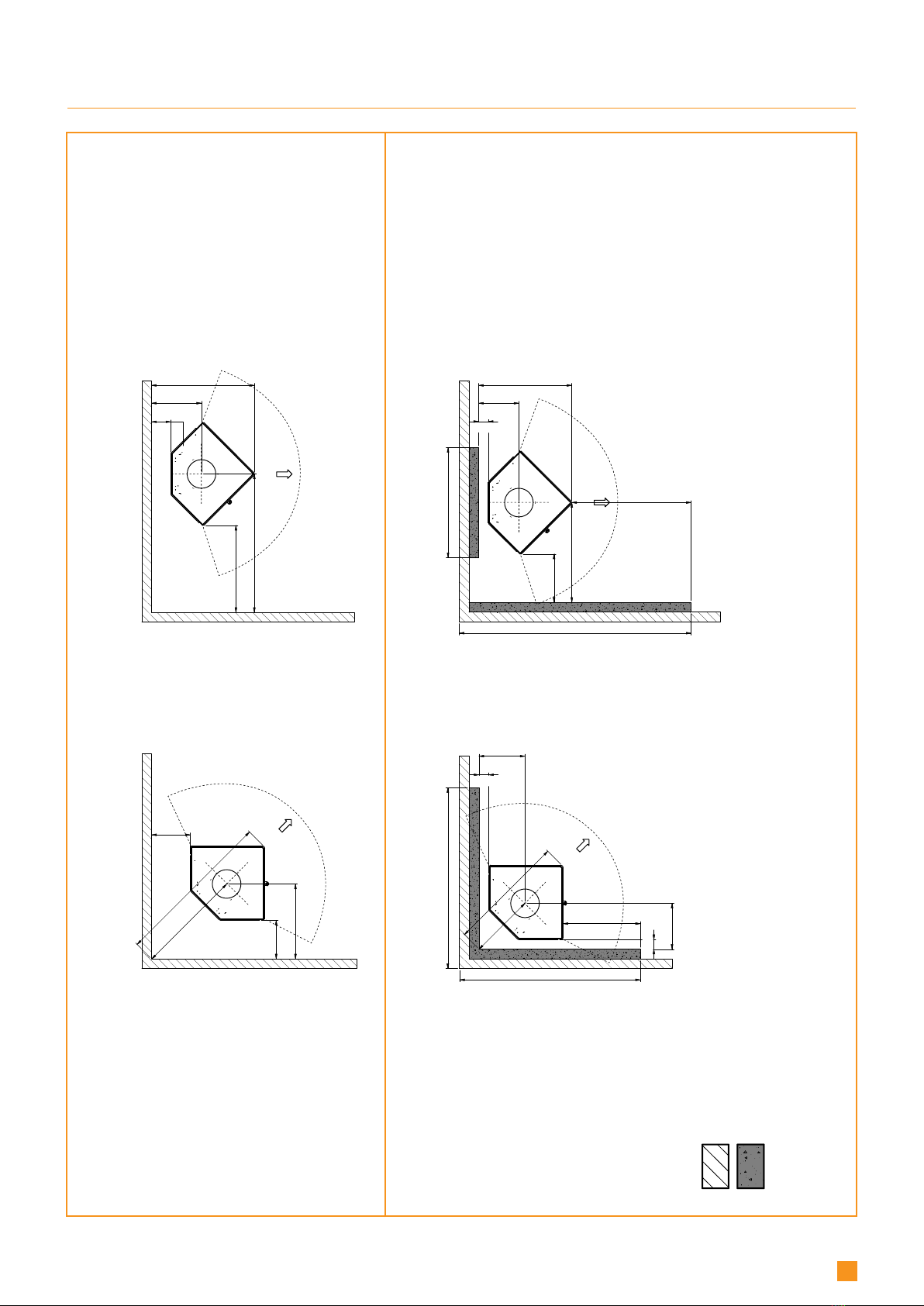

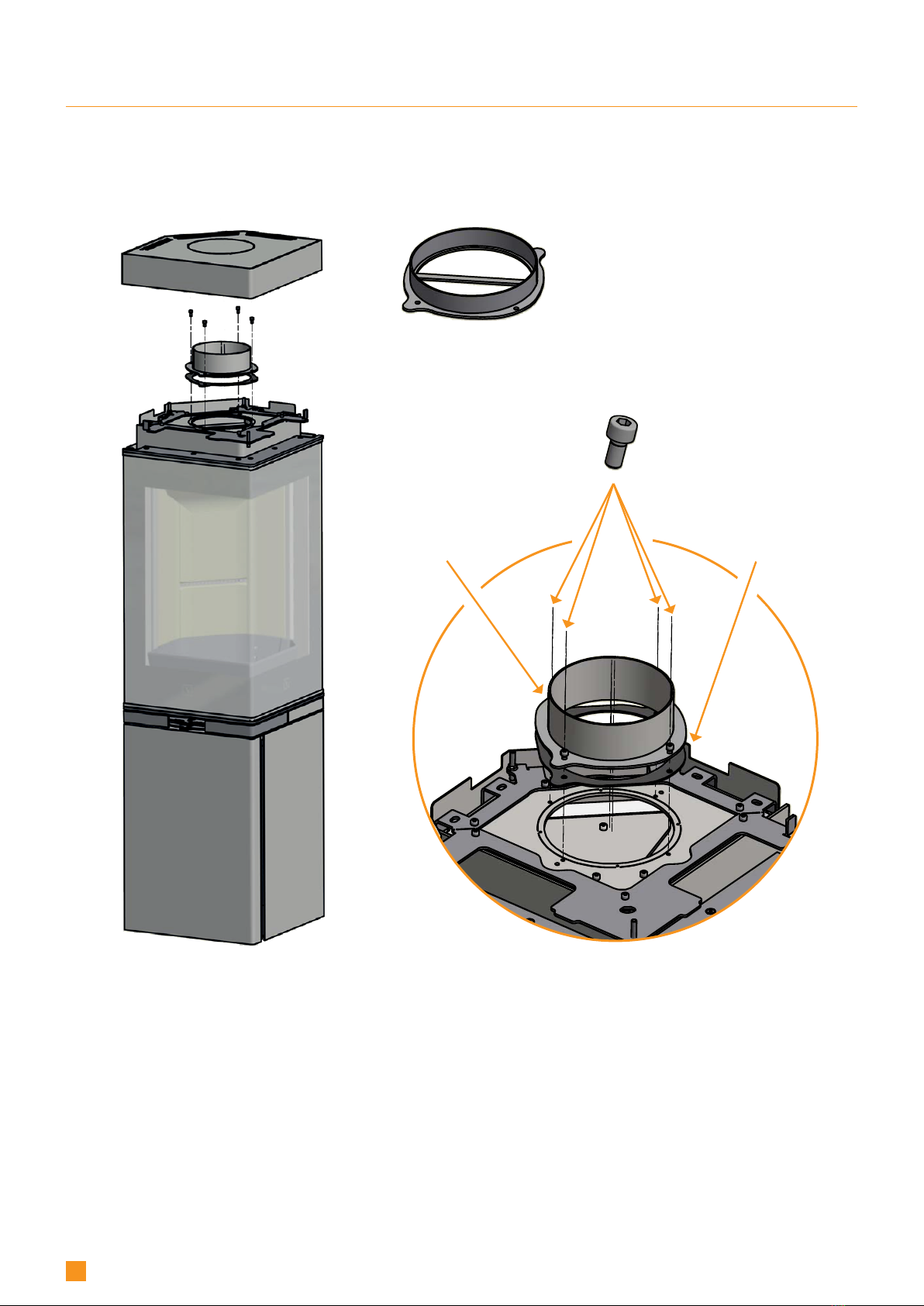

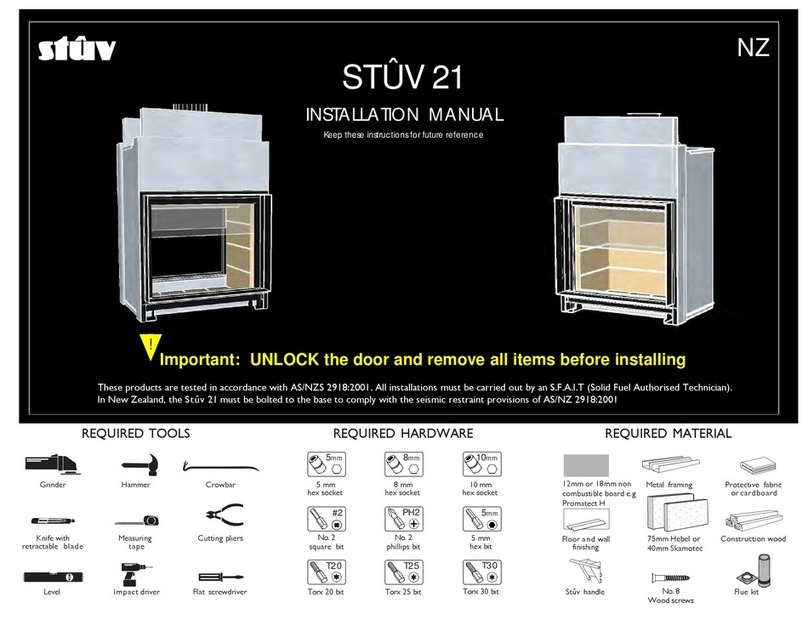

INSTALLATION

¬ The house owner is responsible for ensuring that installation and assembly are in accordance with national and local building

regulations as well as the information provided in this Assembly and Instructions Manual

¬ When you install any kind of fireplace or stove, you must inform the local building and housing authorities. In addition you are

obliged to have the installation inspected and approved by a local chimney sweep prior to commissioning

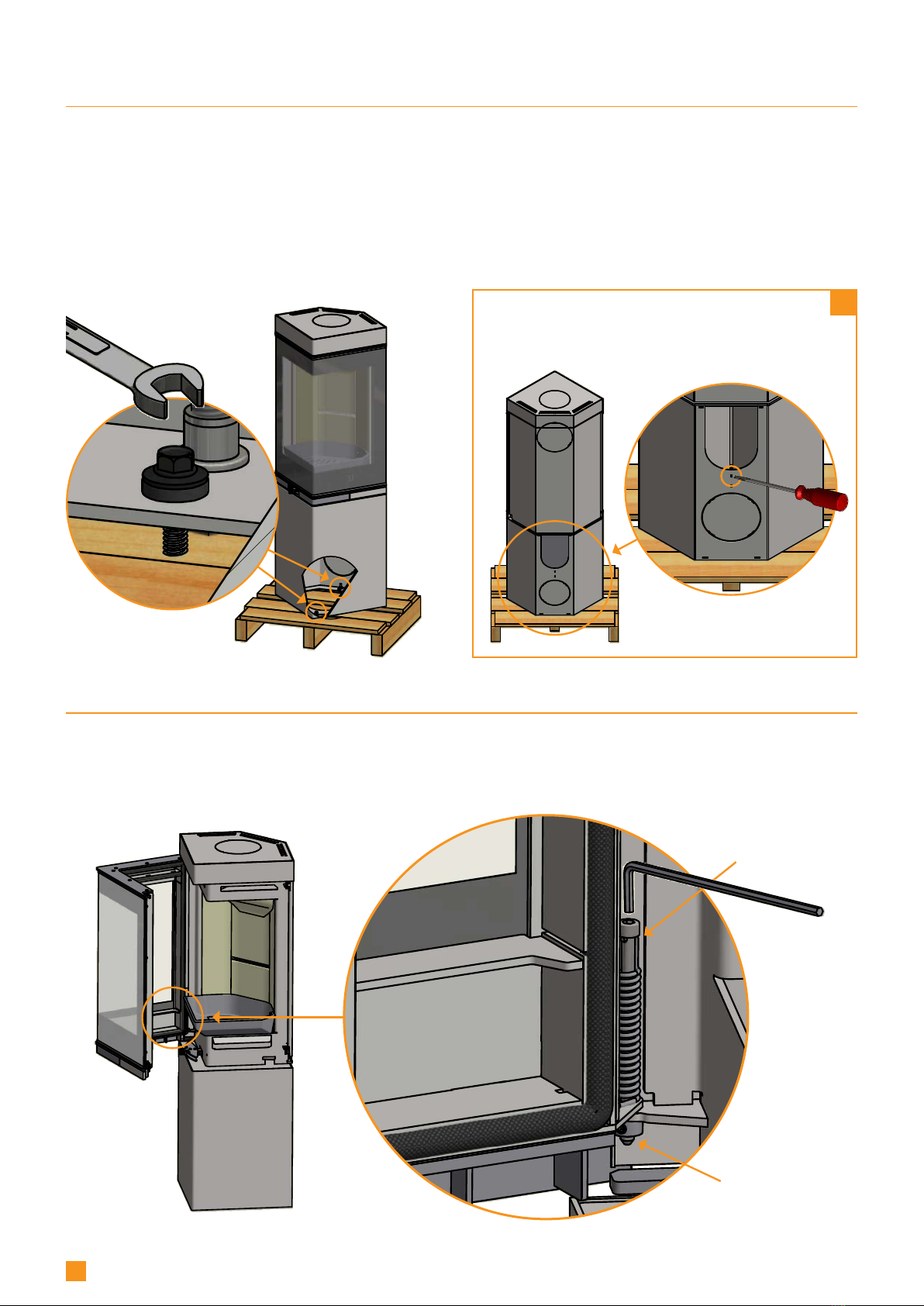

¬ To ensure best-possible functionality and safety for your installation, we advise you to call a professional fitter. Your Scan

dealer will be able to recommend a qualified fitter in your area. For information on Scan Dealers, please go to

www.scan-stoves.com

SAFETY

Any changes made to the product by the dealer, fitter or user could result in the product and safety functions not functioning as

intended. The same applies to the fitting of accessories or extra equipment not supplied by Scan A/S. This could also be the case

if parts that are necessary for the operation and safety of the stove are dismantled or removed.

THE CLEAN AIR ACT 1993 AND SMOKE CONTROL AREAS

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a smoke control area.

It is an offence to emit smoke from a chimney of a building, from a furnace or from any fixed boiler if located in a designated smoke

control area. It is also an offence to acquire an "unauthorized fuel" for use within a smoke control area unless it is used in an

"exempt" appliance ("exempted" from the controls which generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorize smokeless fuels or

exempt appliances for use in smoke control areas in England. In Scotland and Wales this power rests with Ministers in the

devolved administrations for those countries. Separate legislation, the Clean Air (Northern Ireland) Order 1981, applies in

Northern Ireland. Therefore it is a requirement that fuels burnt or obtained for use in smoke control areas have been

"authorized" in Regulations and that appliances used to burn solid fuel in those areas (other than "authorized" fuels) have been

exempted by an Order made and signed by the Secretary of State or Minister in the devolved administrations.

¬ Further information on the requirements of the Clean Air Act can be found here: www.smokecontrol.defra.gov.uk

¬ Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision of smoke

control areas and you can contact them for details of Clean Air Act requirements”

¬ The Scan 80-1, 80-2, 80-3, 80-4, 80-3C and 80-4C have been recommented as suitable for use in smoke control areas when burning

wood logs and when fitted with a mechanical stop to prevent that the secondary air valve cannot be closed lower than 868 mm2

¬ The secondary air valve has been modified, so that is does not close completely but has an opening corresponding to the

position used at the lowest emission test

¬ You can use any type of wood as fuel

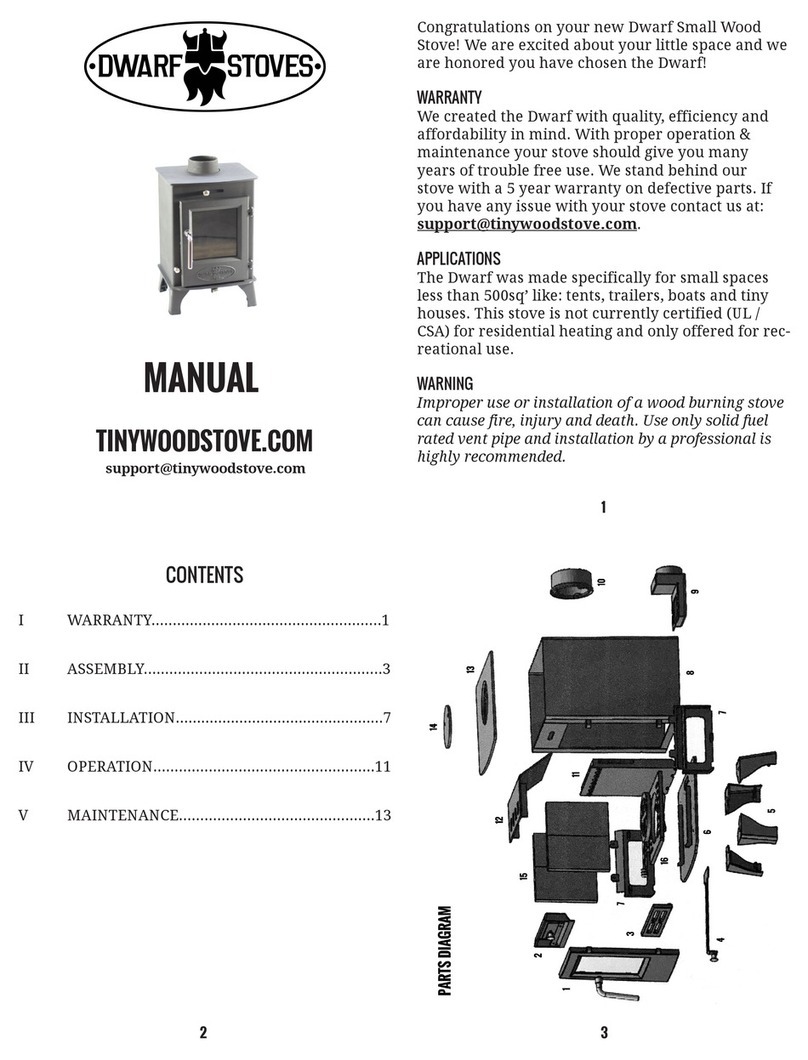

YOU ACHIEVE AN OPTIMAL

BENEFIT OF THE STOVE BY

FOLLOWING THE ADVICE

GIVEN UNDER:

"INSTRUCTIONS FOR HEATING"

PLEASE NOTE!