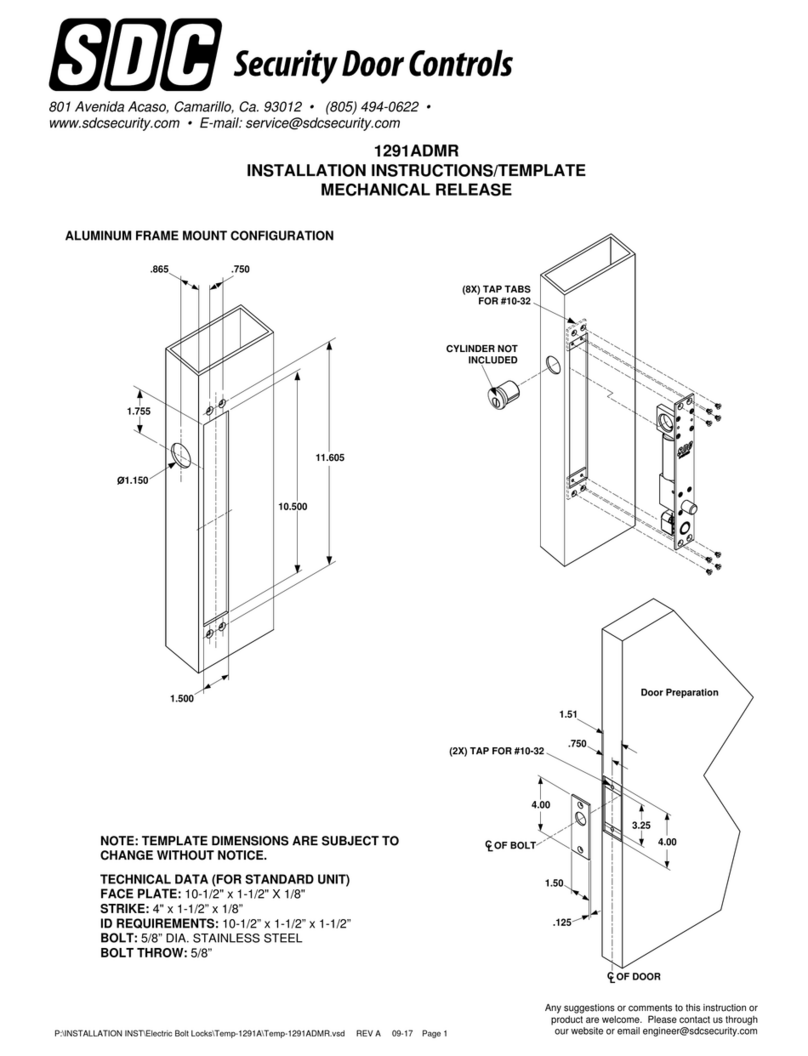

801 Avenida Acaso, Camarillo, Ca. 93012

• (805) 494-0622 • www.sdcsecurity.com

E-mail: service@sdcsecurity.com

P:\INSTALLATION INST\ELECTRIC STRIKES\INST-30 Series\INST-30-4.vsd Rev - 12/10 Page 1

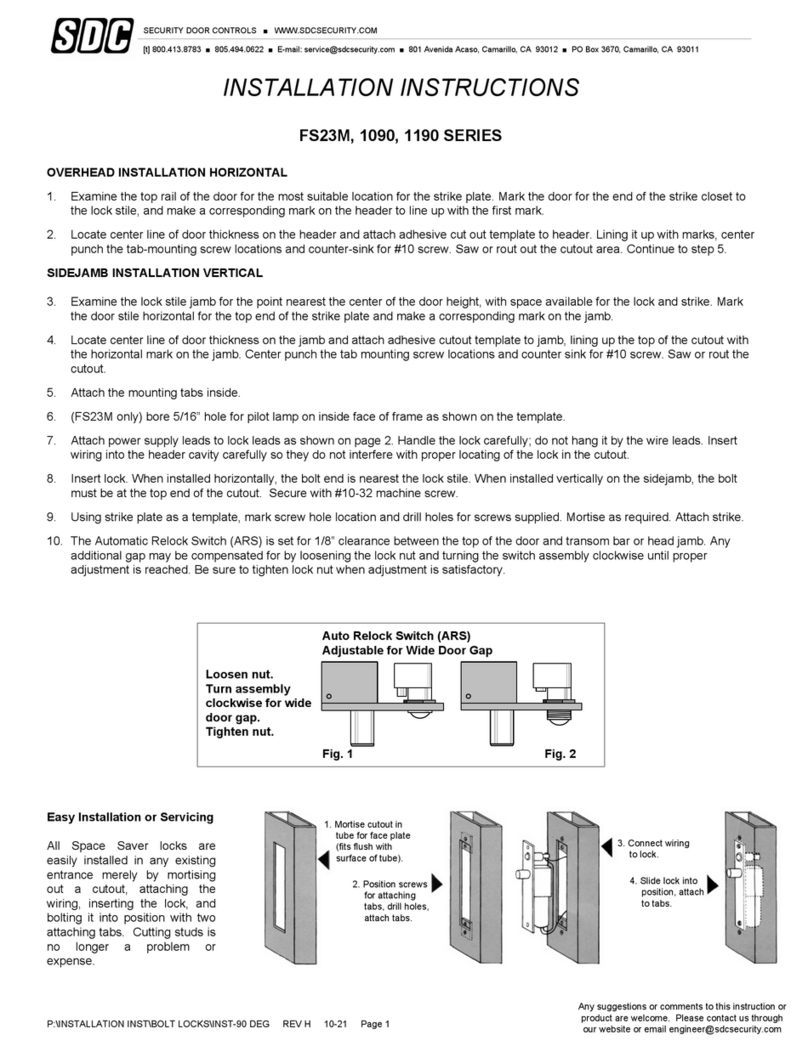

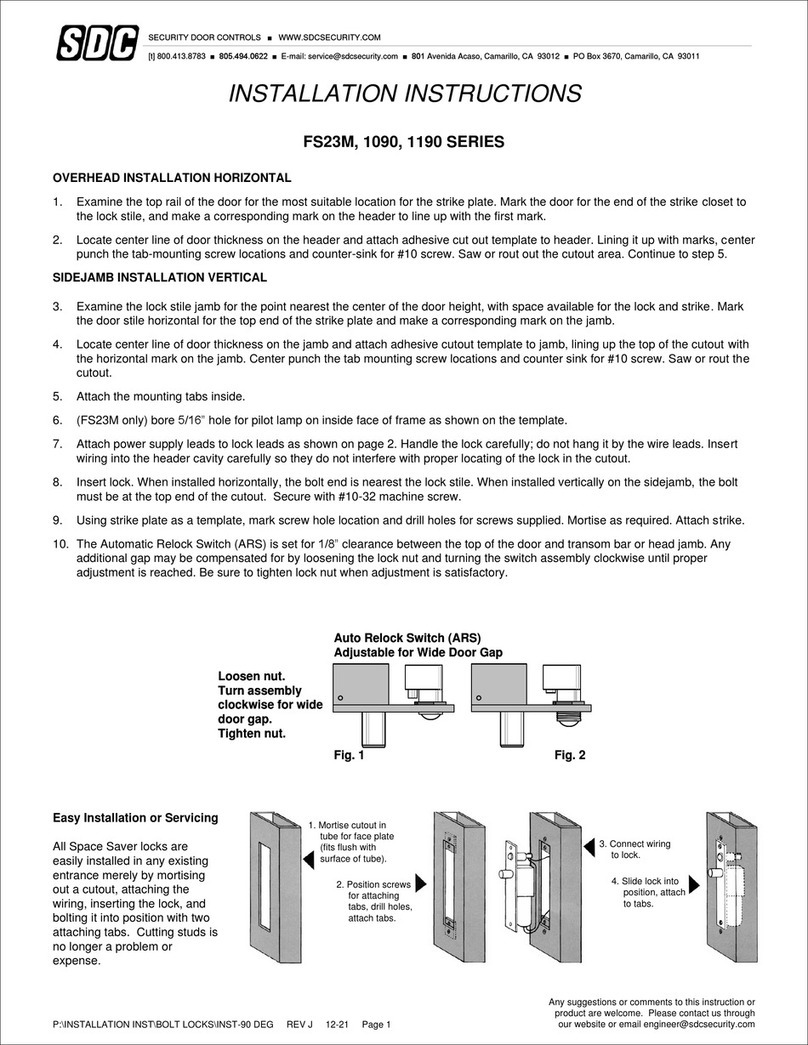

The following instructions cover all models of the 30-4 Electric Strike.

INSTALLATION:

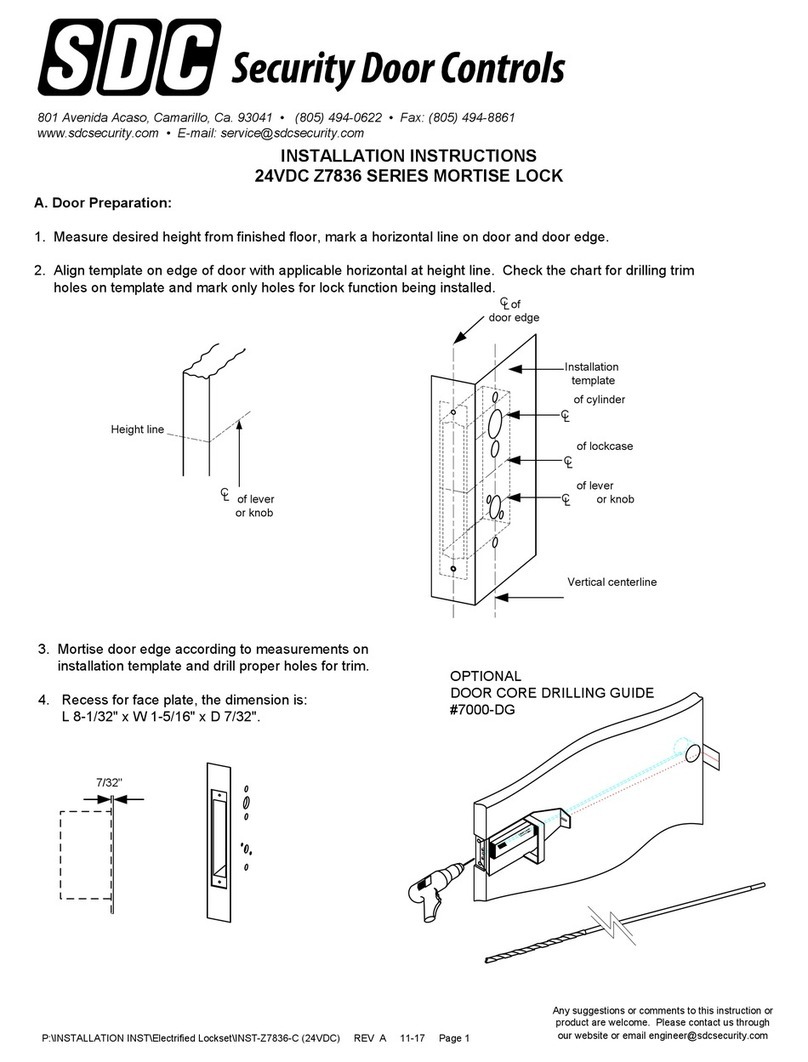

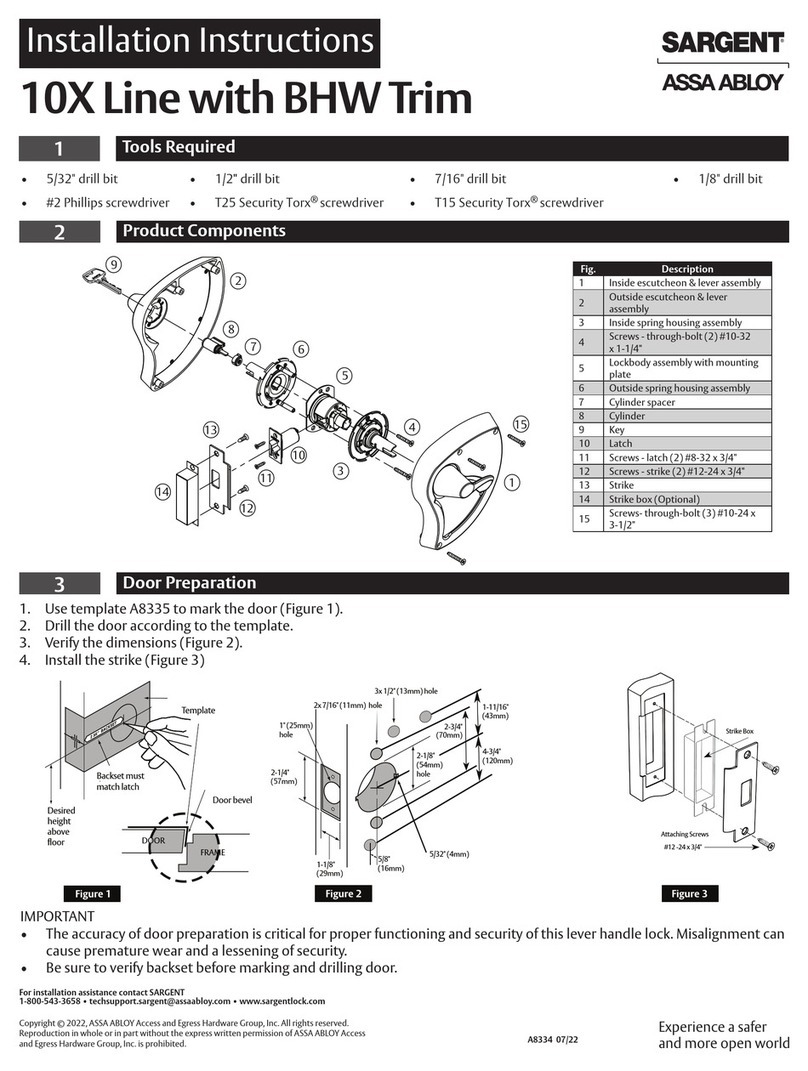

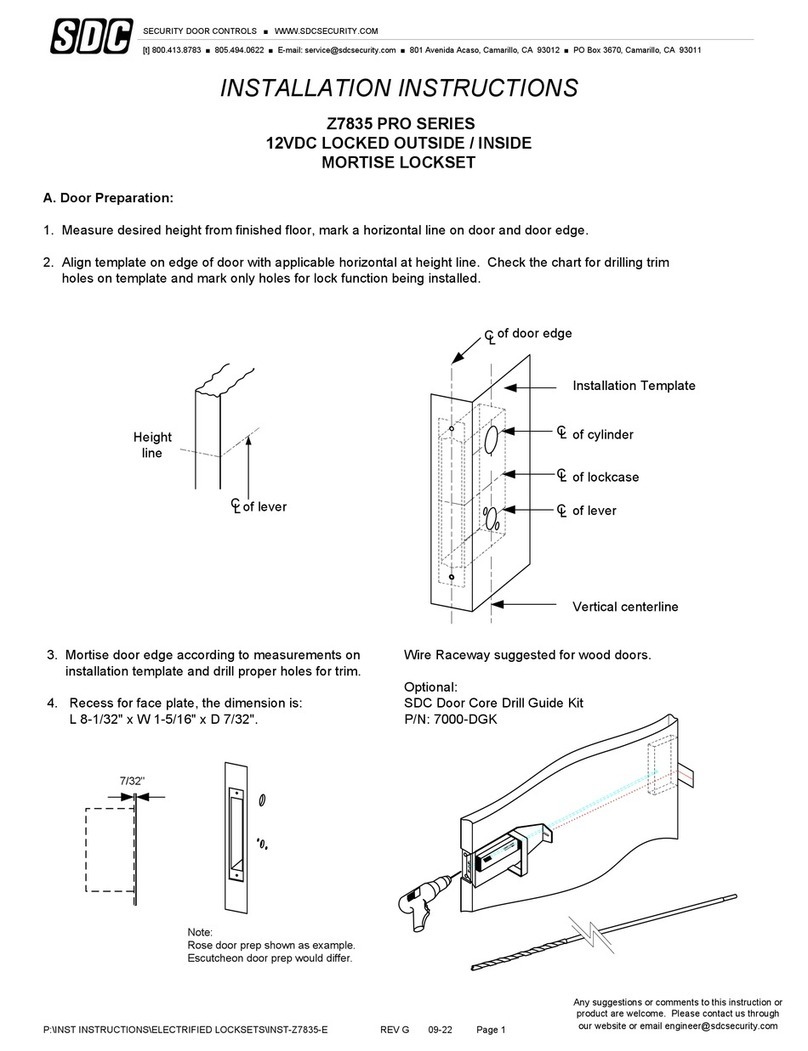

1. For proper installation of the 30-4 Electric Strike, refer to the appropriate template

drawing. The centerline of the latch bolt must be aligned with the centerline of the strike.

NOTE: Not compatible with SDC 6000 Series Rim Devices. Check manufacturers exit

device template for compatibility.

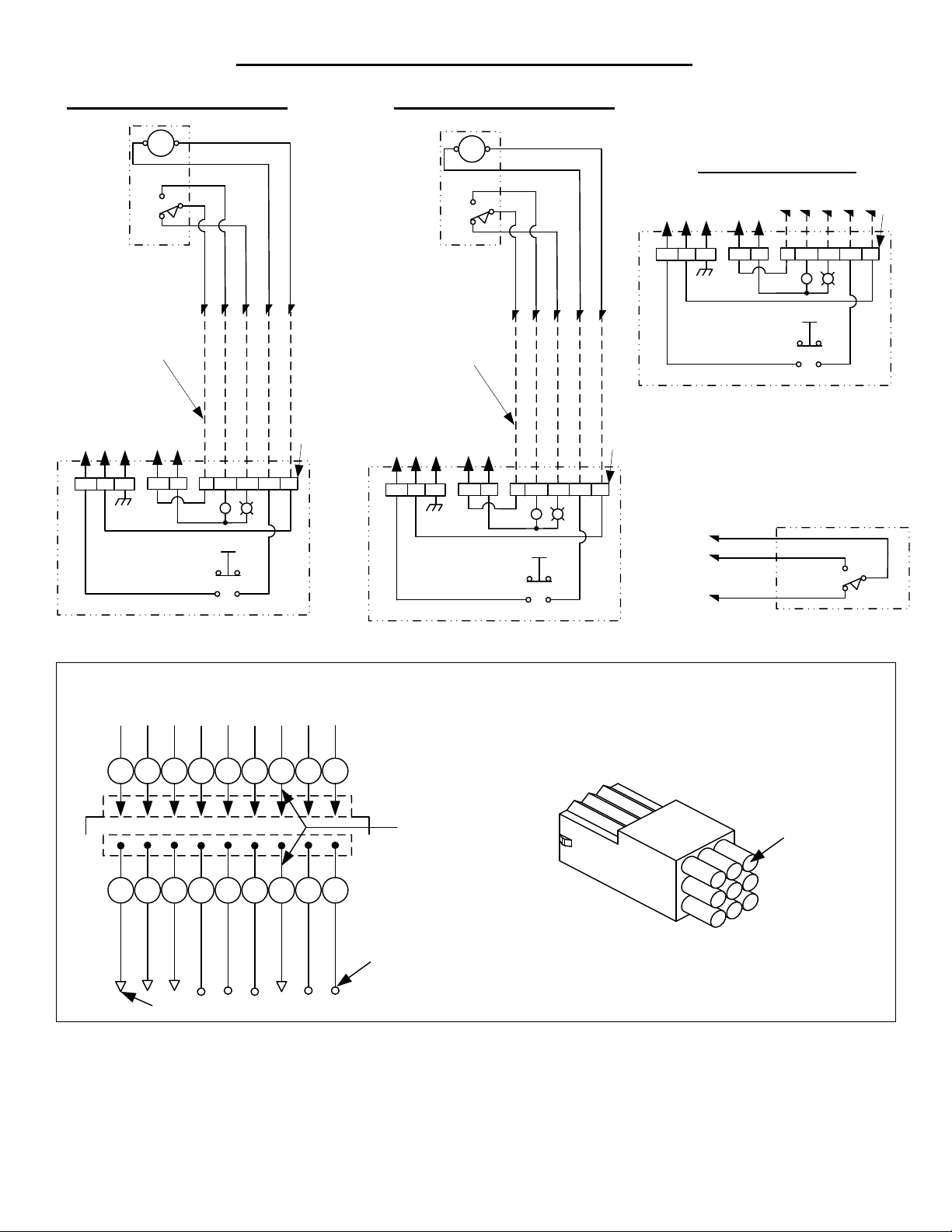

2. Prior to installation, make the necessary wire connections per the appropriate wiring diagram.

3. Proper operating voltage must be supplied to the strike if it is to function correctly. Voltage

at the strike must be within +/-10% of the required voltage listed on the strike label.

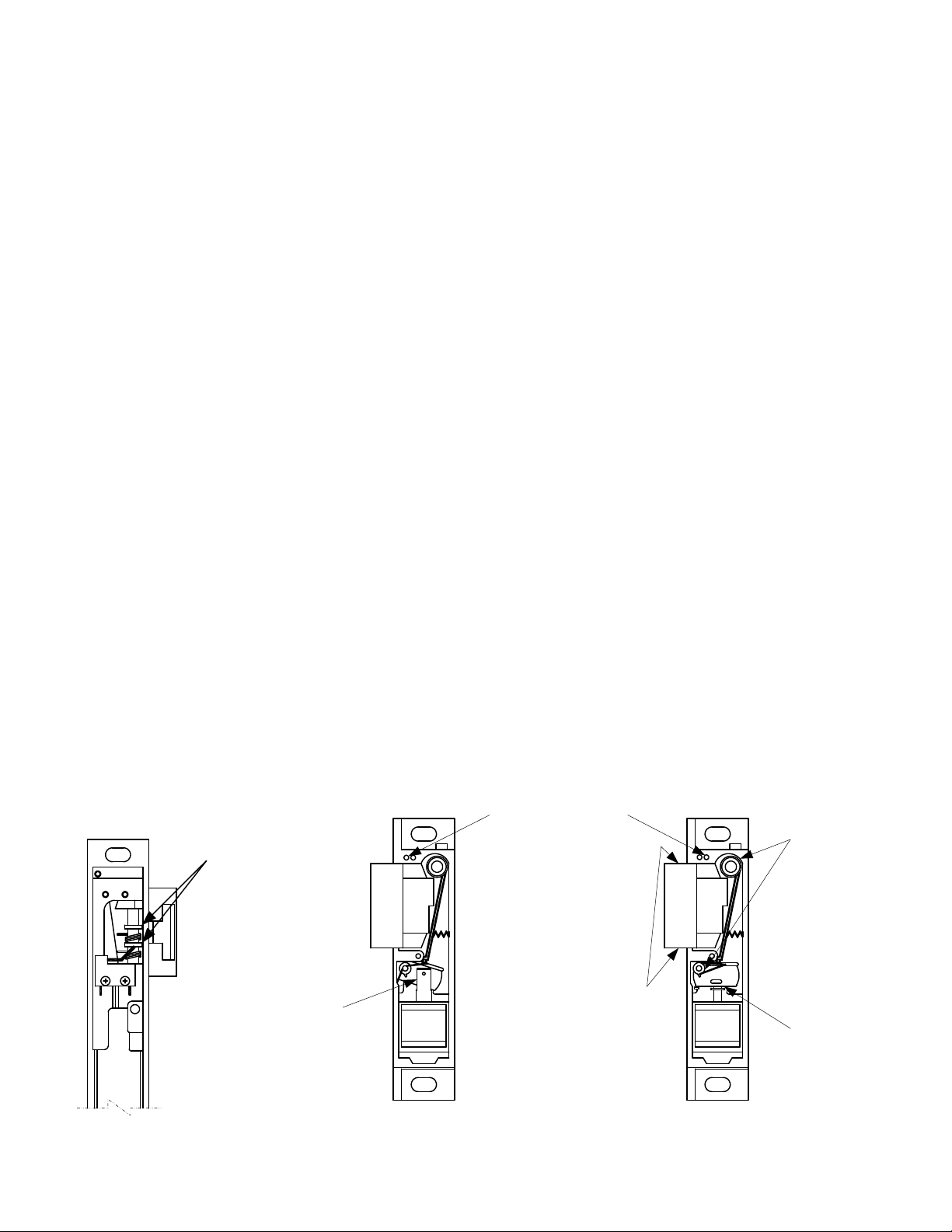

4. To install the strike into the frame opening:

A) Position the wiring either down, up or toward the back of the hollow metal frame,

making sure that it stays completely out of the way of the strike to avoid being pinched

during installation.

B) Mount the strike using the screws supplied.

5. After installation, check the horizontal alignment. Be certain that the centerline of the latch

bolt is aligned with the centerline of the strike.

6. In case of misalignment, there is a 3/16" horizontal adjustment between the strike

mechanism and the face plate. To adjust:

A) Remove mounting screws.

B) Remove strike from frame.

C) Loosen the two (2) #12-24 x 3/8” hex washer head cap screws.

D) Reposition strike and re-tighten cap screws.

OPERATION:

The SDC 30-4 Electric Strike is a solenoid operated device.

1. NON-FAIL SAFE

When power is applied the solenoid pulls the locking cam into the unlocked position

allowing the door to be opened. If power fails the strike will remain locked.

NOTE: Non-fail safe strikes for use in fire rated doors can only be operated by momentary

contact switching (energized only when the push button is held depressed) and can not

be held in the unlocked position.

2. FAIL SAFE:

When the power is applied the solenoid pushes the locking cam into the locked position

and the door can not be opened. If power fails the strike will unlock.

OPERATION NOTE: This product may be provided fail safe or non-fail safe. Fail safe versions

allow exit in the event of a power failure. Fail secure version do not.

Consult with the local authority having jurisdiction concerning the

installation of this type of product and whether listed panic hardware is

required to allow emergency exit from the secured area.

INSTALLATION INSTRUCTIONS

30-4 ELECTRIC STRIKE