Assa Abloy Sargent 10X Line User manual

Other Assa Abloy Door Lock manuals

Assa Abloy

Assa Abloy Yale Essential Series User manual

Assa Abloy

Assa Abloy Effeff Technilock L4 Series User manual

Assa Abloy

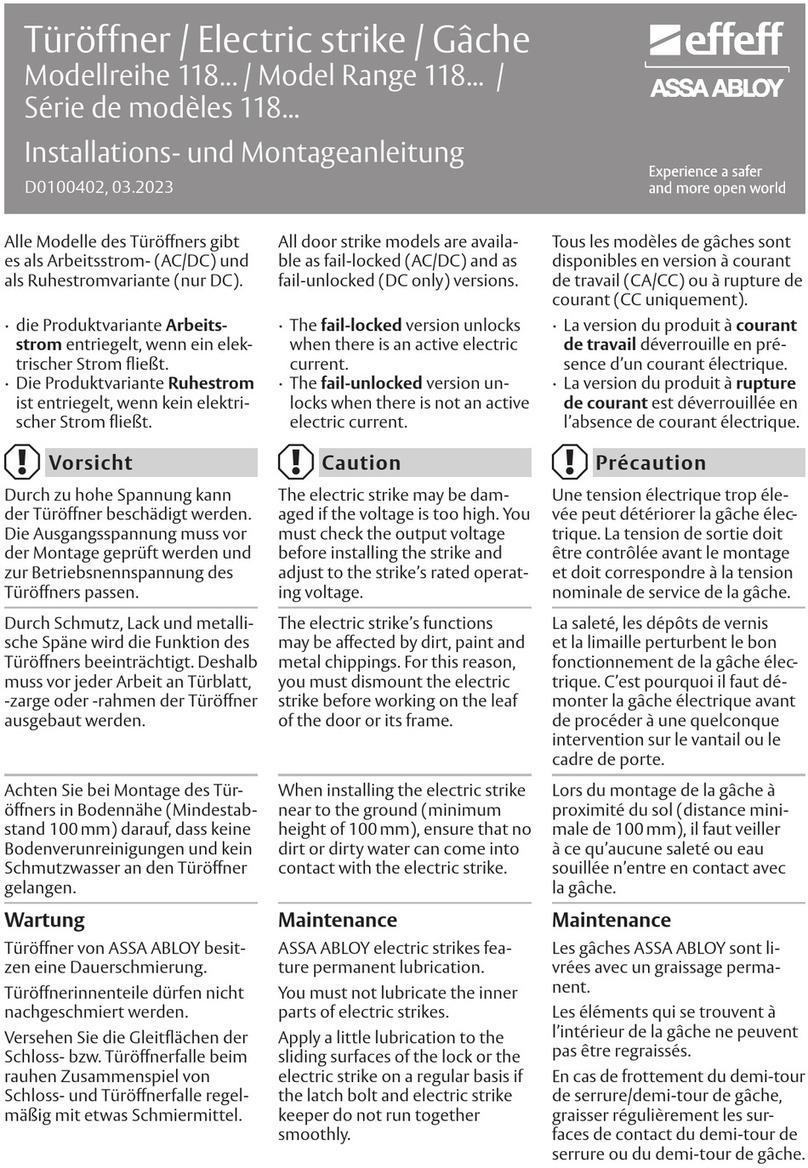

Assa Abloy effeff 118 Series User manual

Assa Abloy

Assa Abloy Sargent PE8500 Series User manual

Assa Abloy

Assa Abloy Yale Assure Lock Lever Technical specifications

Assa Abloy

Assa Abloy PE920 User manual

Assa Abloy

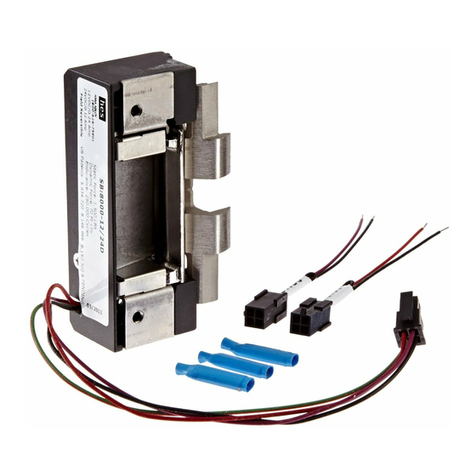

Assa Abloy HES 8000 Series User manual

Assa Abloy

Assa Abloy Sargent 6-Line User manual

Assa Abloy

Assa Abloy Yale YDM3109A User manual

Assa Abloy

Assa Abloy 1489 User manual

Assa Abloy

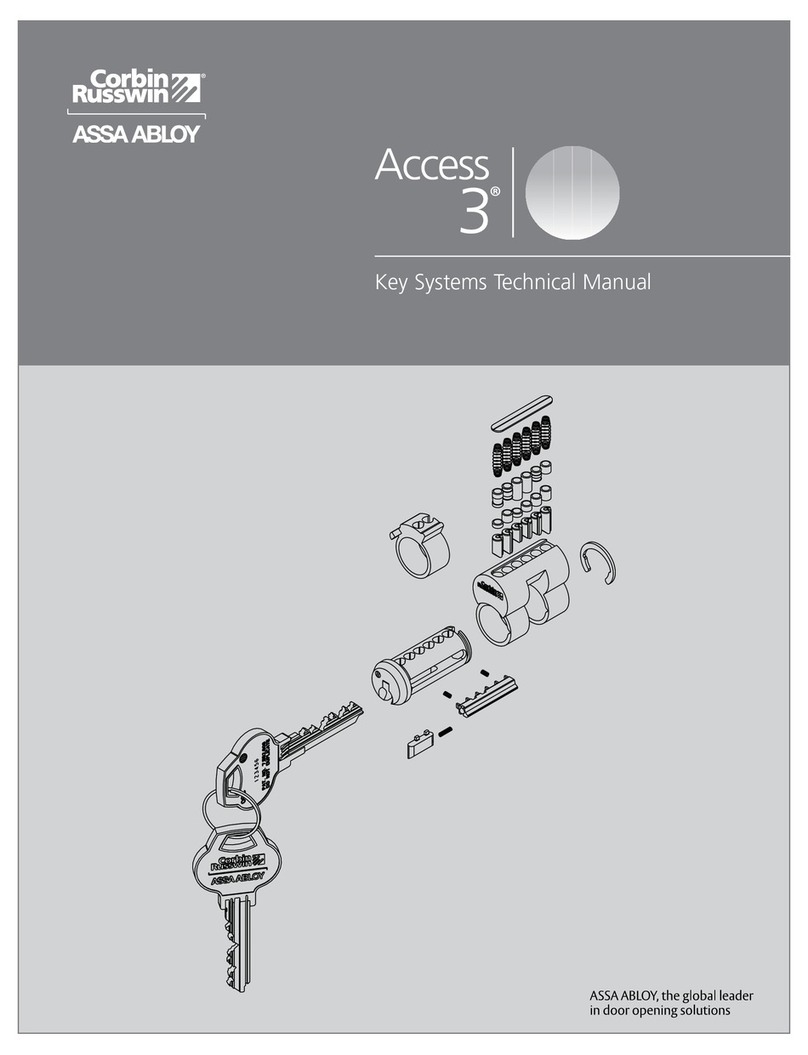

Assa Abloy Access 3 User manual

Assa Abloy

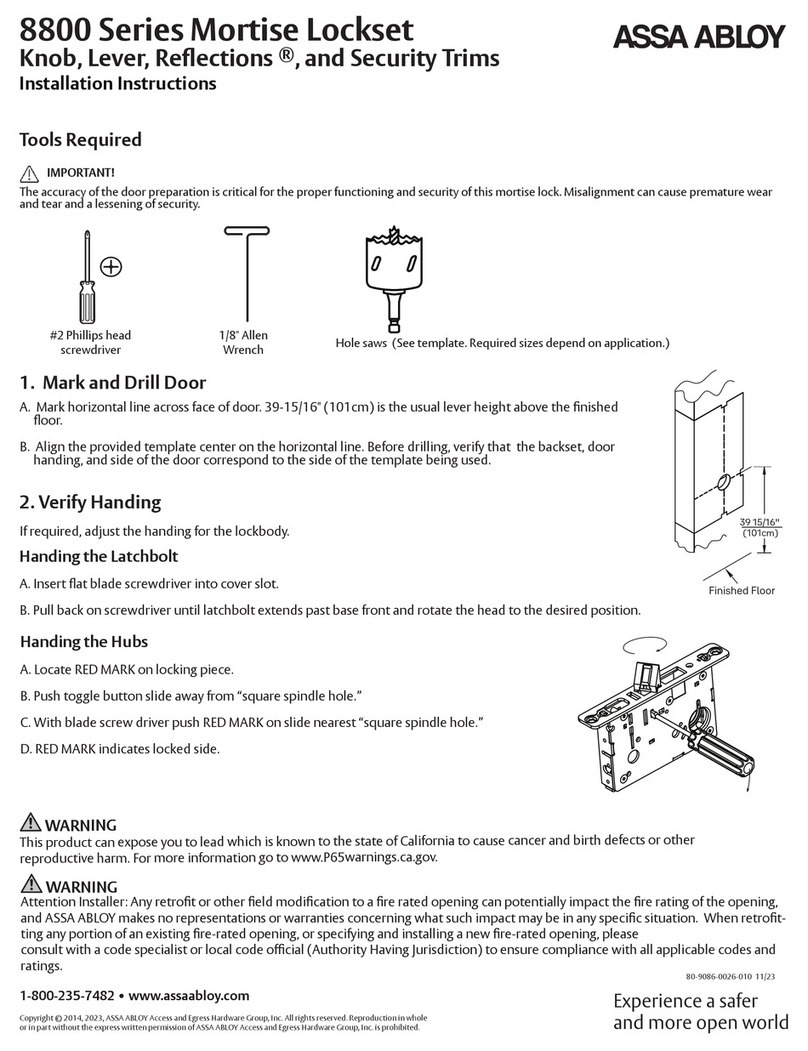

Assa Abloy 8800 Series User manual

Assa Abloy

Assa Abloy Corbin Russwin MP9800 Series User manual

Assa Abloy

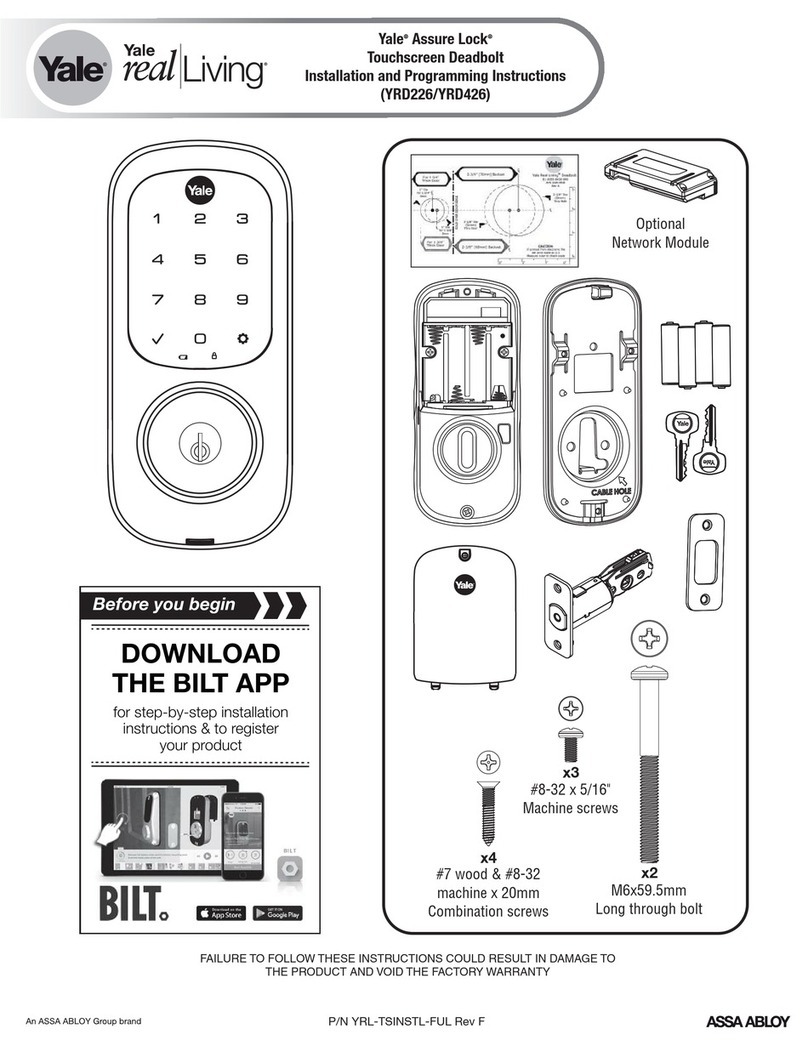

Assa Abloy Yale Real Living Assure Lock YRD226 Technical specifications

Assa Abloy

Assa Abloy SARGENT KP8977 Guide

Assa Abloy

Assa Abloy ENTR User manual

Assa Abloy

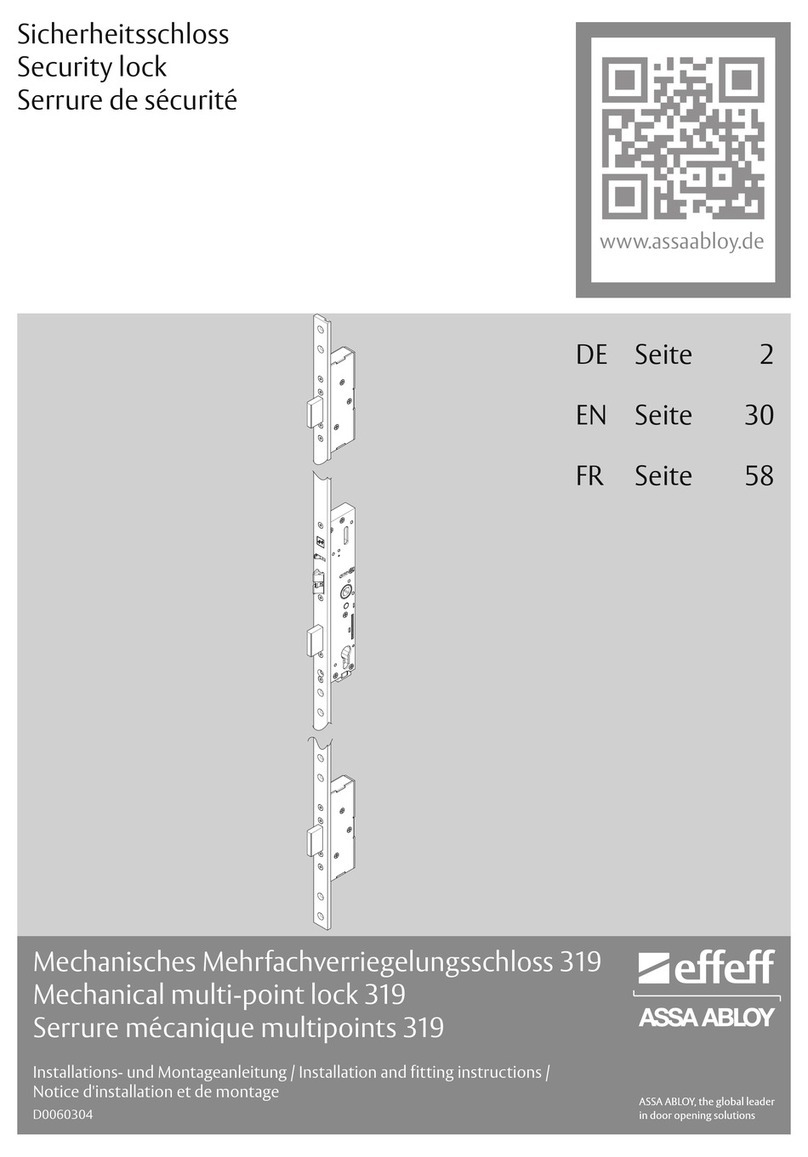

Assa Abloy Effeff 319 Series User manual

Assa Abloy

Assa Abloy Aptus Yale Doorman User manual

Assa Abloy

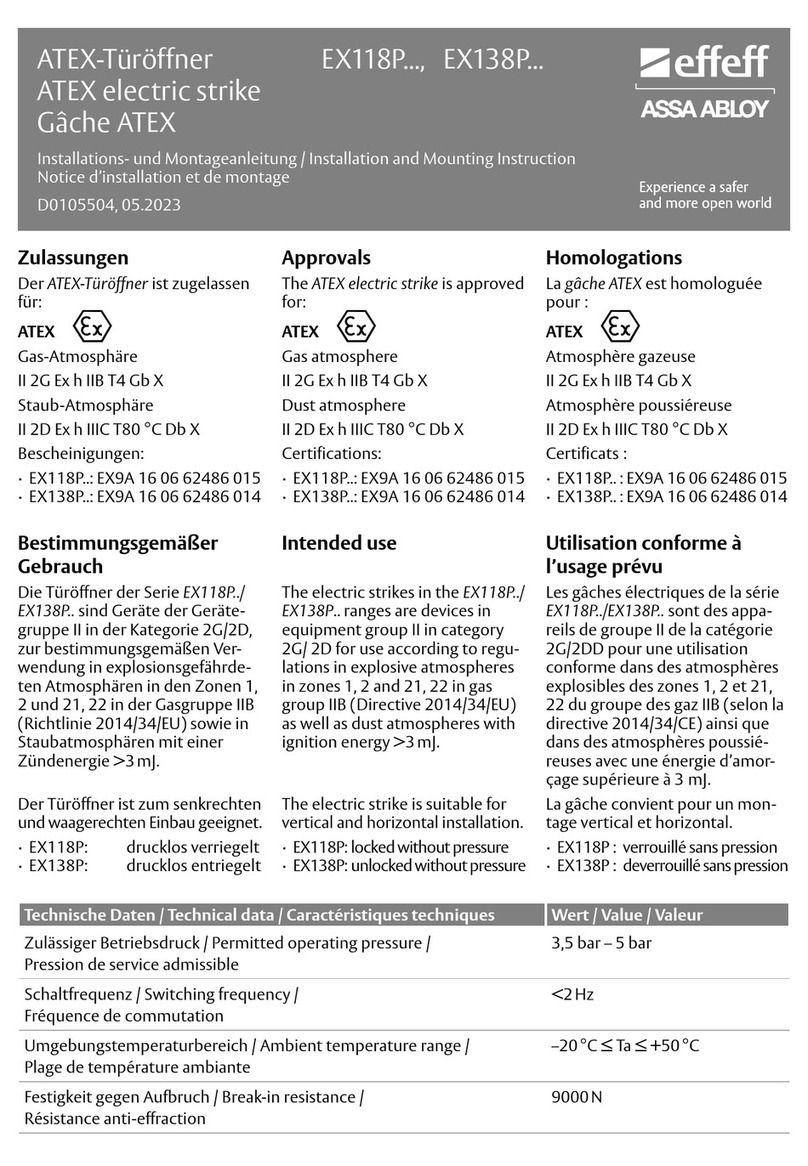

Assa Abloy Effeff EX118P Series User manual

Assa Abloy

Assa Abloy SARGENT7800 Series User manual

Popular Door Lock manuals by other brands

SCOOP

SCOOP Pullbloc 4.1 FS Panik Assembly instruction

Yale

Yale MORTISE 8800 SERIES installation instructions

Siegenia

Siegenia KFV AS3500 Assembly instructions

Saflok

Saflok Quantum ädesē RFID installation instructions

ArrowVision

ArrowVision Shepherd 210 installation manual

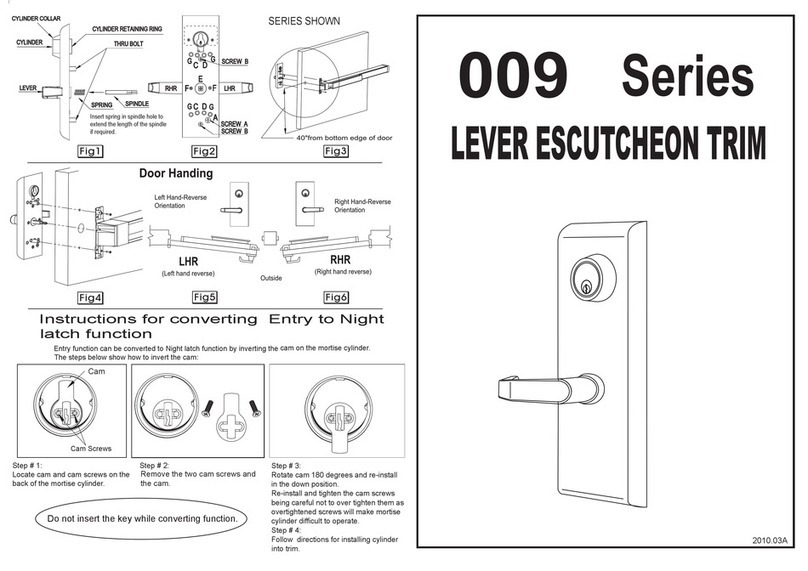

Baldwin

Baldwin 009 Series quick start guide