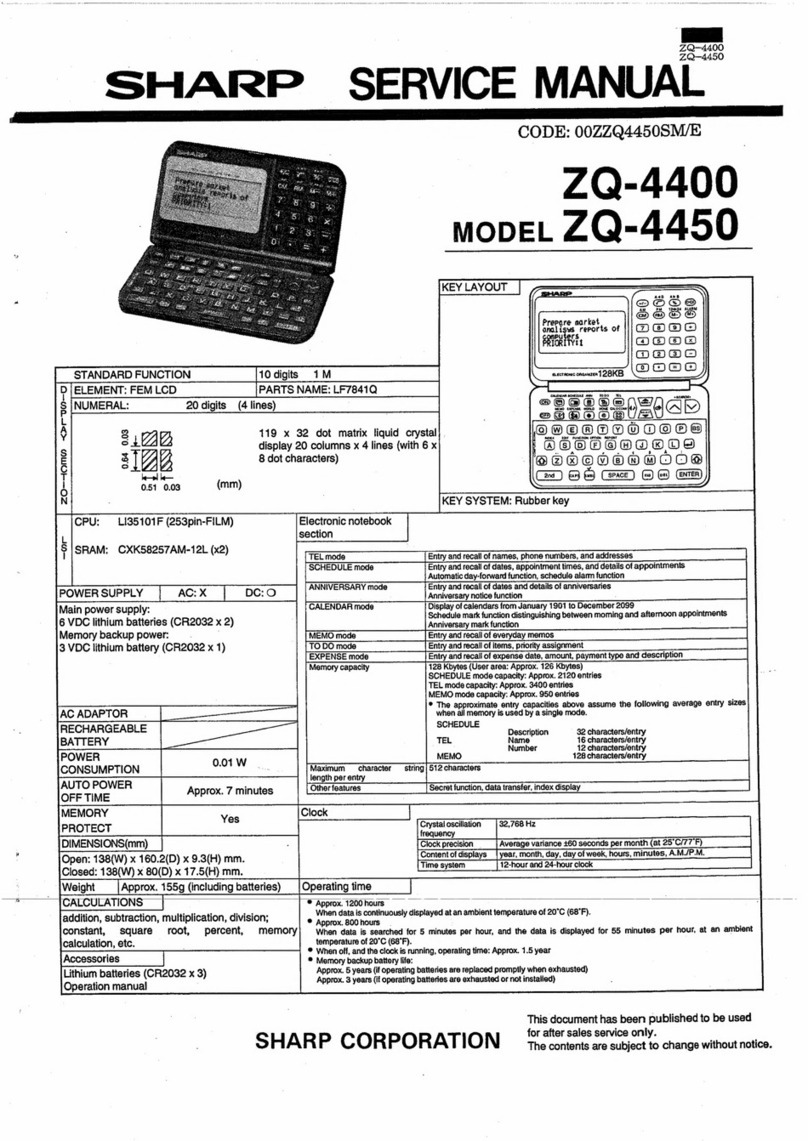

About power source

•You can use two AA alkaline batteries or the optional NiMH Re-

chargeable Battery Pack to power your unit, or the AC adaptor

included in the optional Docking Station Kit.

•If the main batteries are not installed, or are depleted, the unit will

not function even when connected to an AC power source.

•Caution: When the main batteries are depleted, replace them

promptly with new batteries. If the depleted main batteries are not

replaced, the backup battery will be drained more quickly than

normal, and data loss may occur after about 2 weeks.

•?????

Important points to remember when installing new batteries:

•Be sure not to use any of the following as main batteries: manga-

nese batteries or nickel cadmium rechargeable batteries. These

are easily mistaken for alkaline batteries.

•Do not remove the main batteries and the backup battery at the

same time (this will result in the loss of all stored data).

•Backup important data before replacing batteries.

•Replace both main batteries at the same time with new batteries of

the same type.

•When the main battery low warning message and the backup

battery low warning message appear at the same time, replace the

backup battery first. After the backup battery replacement, turn on

your unit and make sure the backup battery low message is gone,

then you can proceed to replace the main batteries.

Caution:

•Keep batteries out of the reach of children.

•Danger of explosion if batteries are incorrectly replaced. Replace

only with the same or equivalent type recommended by the manu-

facturer. Discard used batteries according to the manufacturer’s

instructions.

•Backup battery: Replace battery with Panasonic type CR2032

only. Use of another battery may present a risk of fire of explosion.

See operation manual for safety instructions.

•Batteries may explode if mistreated. Do not recharge except the

optional NiMH Rechargeable Battery Pack, disassemble or dis-

pose of in fire.

Connecting the unit to your PC

You can connect the unit to your desktop PC to backup data, syn-

chronize activities, transfer files, etc.

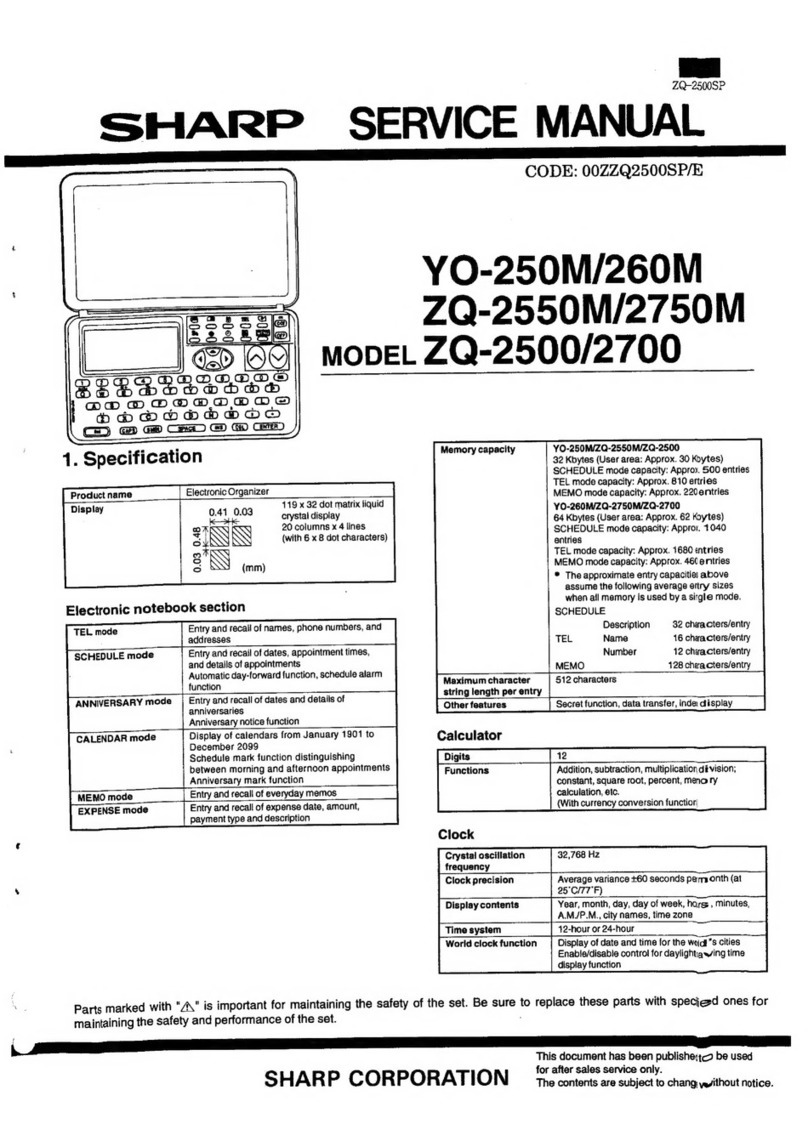

Installing the Windows CE Services software

Before connecting the unit to a PC, you need to install the Windows

CE Services software on your PC and specify a serial port for use

with the unit. Use the supplied CD-ROM from Microsoft for the instal-

lation.

If this is the first time you are connecting the unit to your PC, the Set

Up New Partner Wizard will appear on the PC. Follow the instructions

to complete the setup.

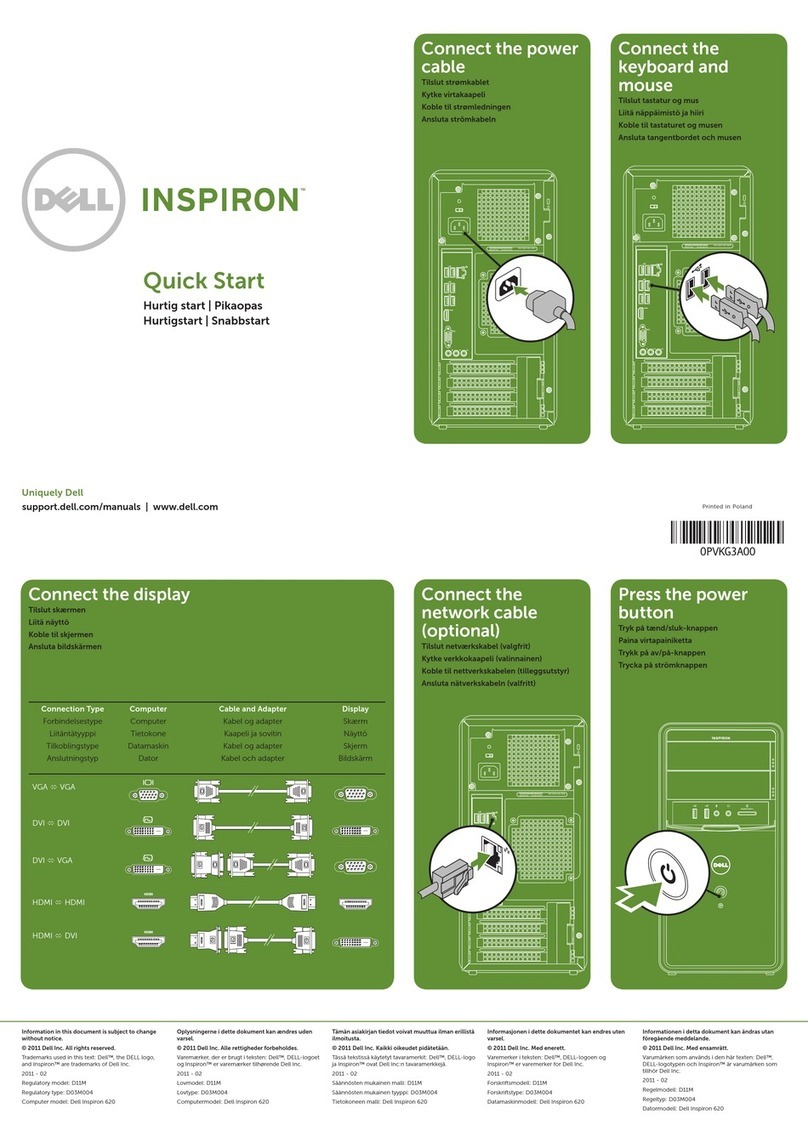

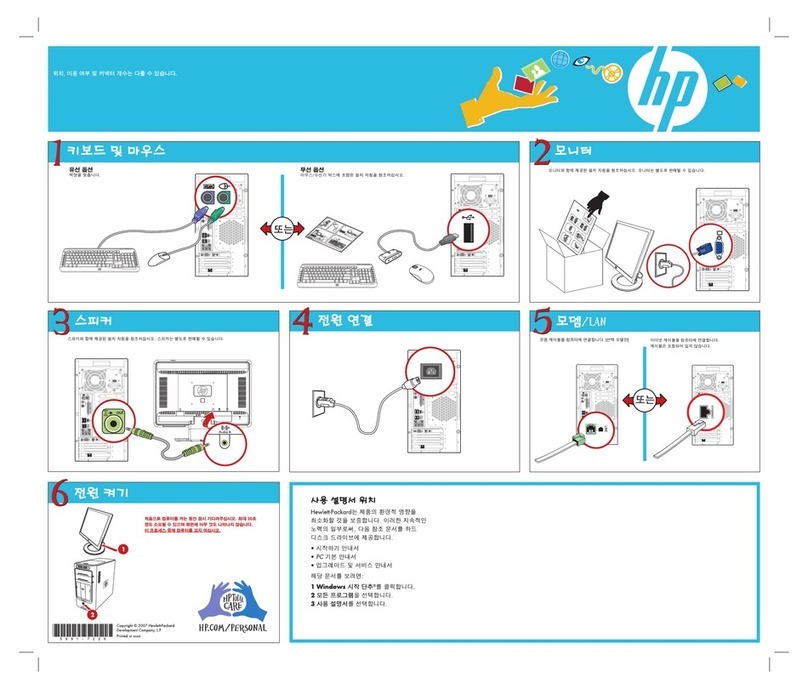

Connect the unit to the desktop PC as follows:

1. Turn on the unit.

2. Flip open the serial port cover and push it into the unit as shown.

3. Insert the 18-pin end of the supplied serial cable into the serial

port on the unit.

4. Insert the other end of the cable into the serial port on your PC

that you specified during the Windows CE Services installation.

Using the infrared port for file transfer

You can use the built-in infrared port to transfer files with other hand-

held PCs compliant with the IrDA (115.2 kbps) standards.

Make sure both handheld PCs are turned on, then take the following

steps:

1. Align the two handheld PCs so that their infrared ports are facing

each other.

2. From the sending unit, tap to select the file to transfer.

3. On the receiving unit, tap Receive from the File menu, then spec-

ify the type of the sending unit.

4. On the sending unit, tap Send from the File menu, or tap Infrared

Recipient from Send To of the File menu. Specify the type of the

receiving unit, then start sending the data.

– 37 –