CHAPTER 1. SPECIFICATIONS

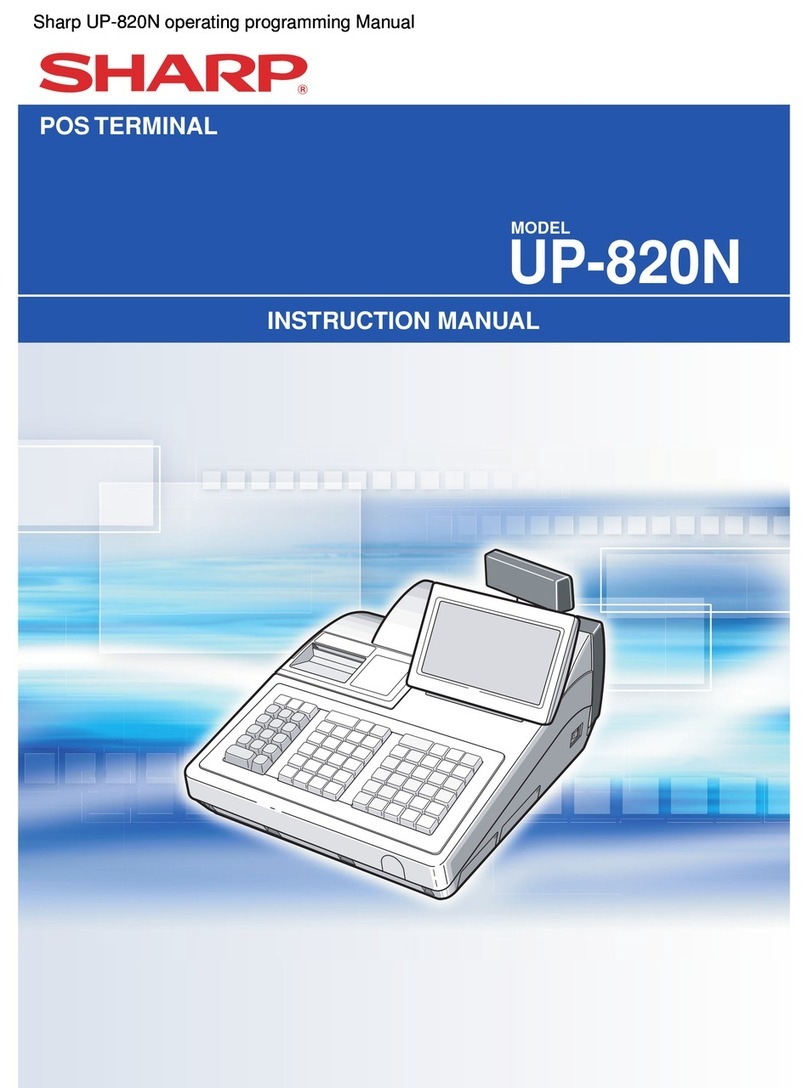

1. Appearance

AC cord

Plug your POS terminal into a wall outlet before using.

Power switch

Set the power switch to the ON ( I ) position after plugging your POS

terminal.

2. Rating

ITEM SPECIFICATIONS

External dimensions 11.6 (W) ×16.3 (D) ×12.6 (H) in.

approximately (295 (W) ×414.5 (D) ×

320 (H) mm)

Weight Approximately 13.9 lb. (5.9 kg)

Power source 120V AC ±10%, 60 Hz

Power consumption Operating : 63W

Working temperature

and humidity 32 to 104°F (0 to 40°C)

10 to 90%

3. Hardware

3-1. Display

ITEM SPECIFICATIONS NOTE

Type DSTN color LCD with back

light With 256 colors

Screen size 10.4" Full screen

Dot format 640 (W) ×480 (H) dots

Dot size 0.33 ×0.33 mm

Control VGA

3-2. Keyboard

ITEM SPECIFICATIONS NOTE

Type Touch key

(Analog touch panel)

Number of key

positions 4096 (W) ×4096 (H)

positions

Control Mouse emulation

3-3. PC system

ITEM SPECIFICATIONS NOTE

CPU Pentium processor

Chip set FireStar Plus:

82C700U3.2

Graphic controller VGAC : MN89305

Main memory

(for executing MS-DOS,

Application software)

Standard : 8

Mbytes EDO type

Max. : 40 Mbytes adding S.O.DIMM

Video RAM 1 Mbytes EDO type

BIOS ROM 512 Kbytes Flash ROM

OS (MS-DOS) ROM 4 Mbytes Mask ROM

ROM disk memory

(for stored Application

software)

Standard : 2

Mbytes Flash ROM

Max. : 6 Mbytes adding UP-F04RB

RAM disk memory

(for POS data) Standard : 1

Mbytes PS-RAM

Max. : 3 Mbytes adding UP-P02MB

Keyboard controller M38802M270

Super I/O M5113 A2

POS system controller PSC2 : LZ9AM22

3-4. Serial port

D-SUB 9-pin connector COM1 and COM2 are equipped.

In order to supply +5V power, CI signal and +5V power supply of

COM1 and COM2 can be switched.

2 channels of RJ45 Connector COM port are equipped.

COM3 and COM4 or original I/O address (COM5 and COM6) can be

selected as the 2 channels of RJ45 COM port.

COM1 & COM2: D-sub 9 pin

Pin No. Signal Function I/O

1 CD Data Carrier Detect I

2 RD Receive Data I

3 SD Send Data O

4 ER Data Terminal Ready O

5 SG Signal Ground —

6 DR Data set Ready I

7 RS Request to Send O

8 CS Clear to Send I

9 CI/+5V Ring Indicate / +5V I/–

COM3 or COM5: Modular jack RJ45 8 pin

Pin No. Signal Function I/O

1 RS Request to Send O

2 ER Data terminal Ready I

3 SD Send Data O

4 SG/(+5V) Signal Ground/(+5V) —

5 SG Signal Ground –

6 RD Receive Data I

7 DR Data set Ready I

8 CS Clear to Send I

1 – 1