Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003277

Page 2

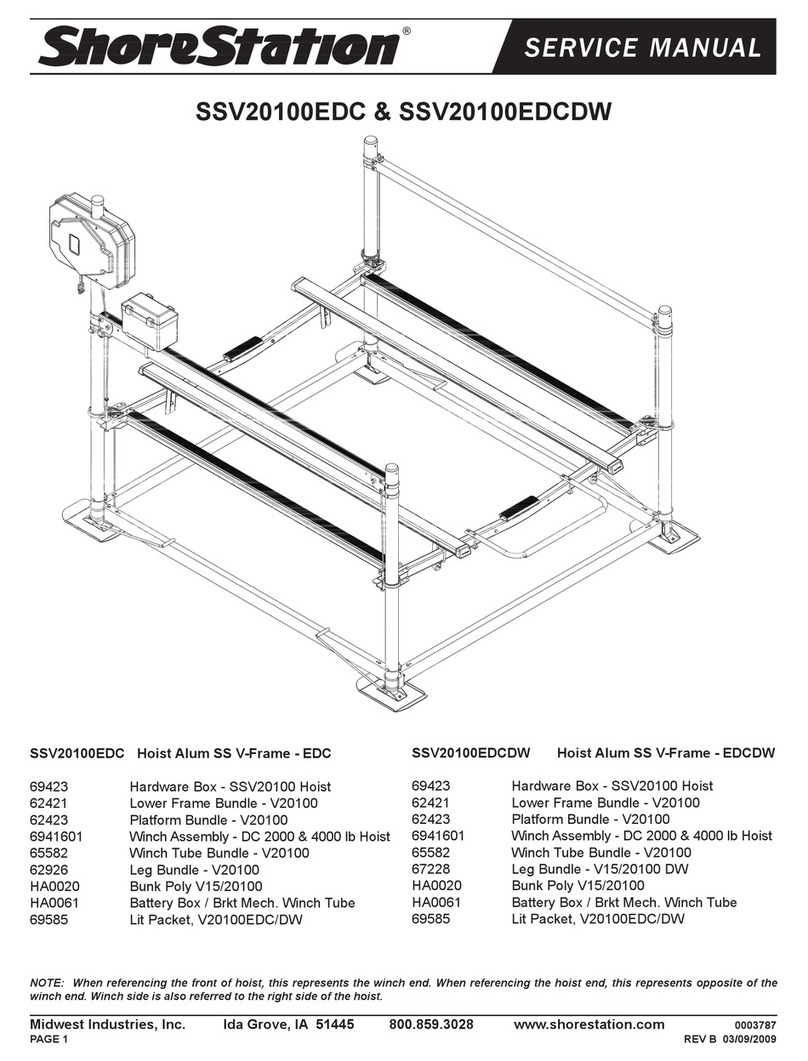

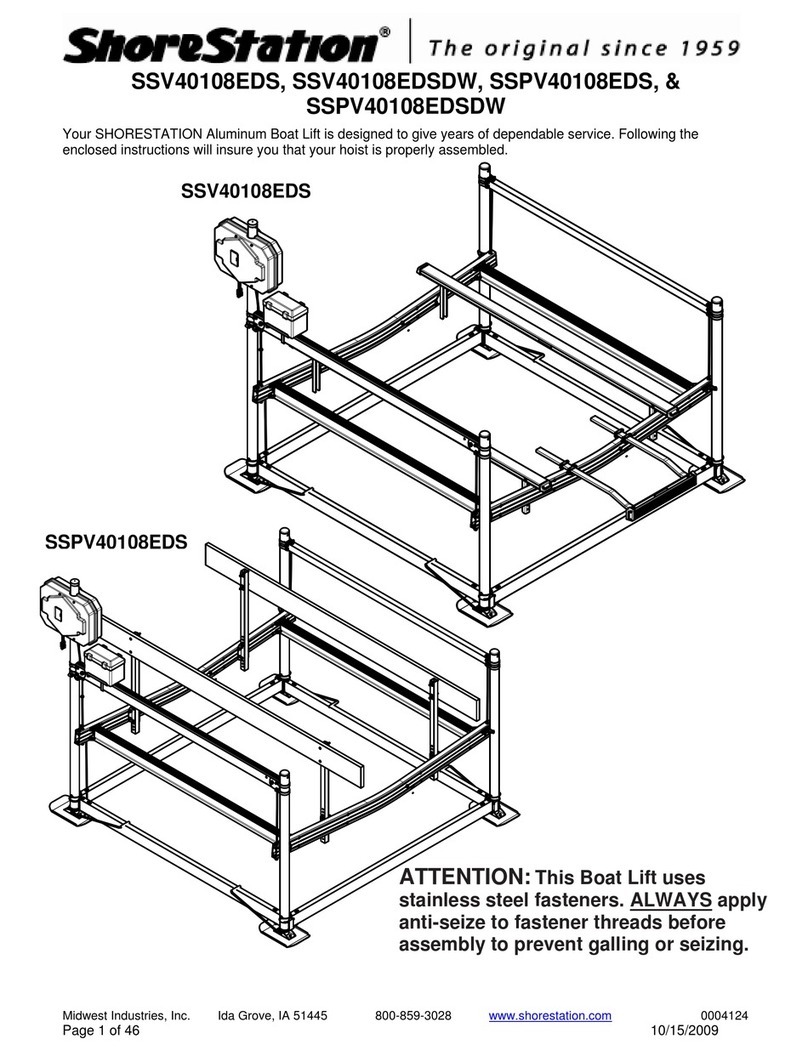

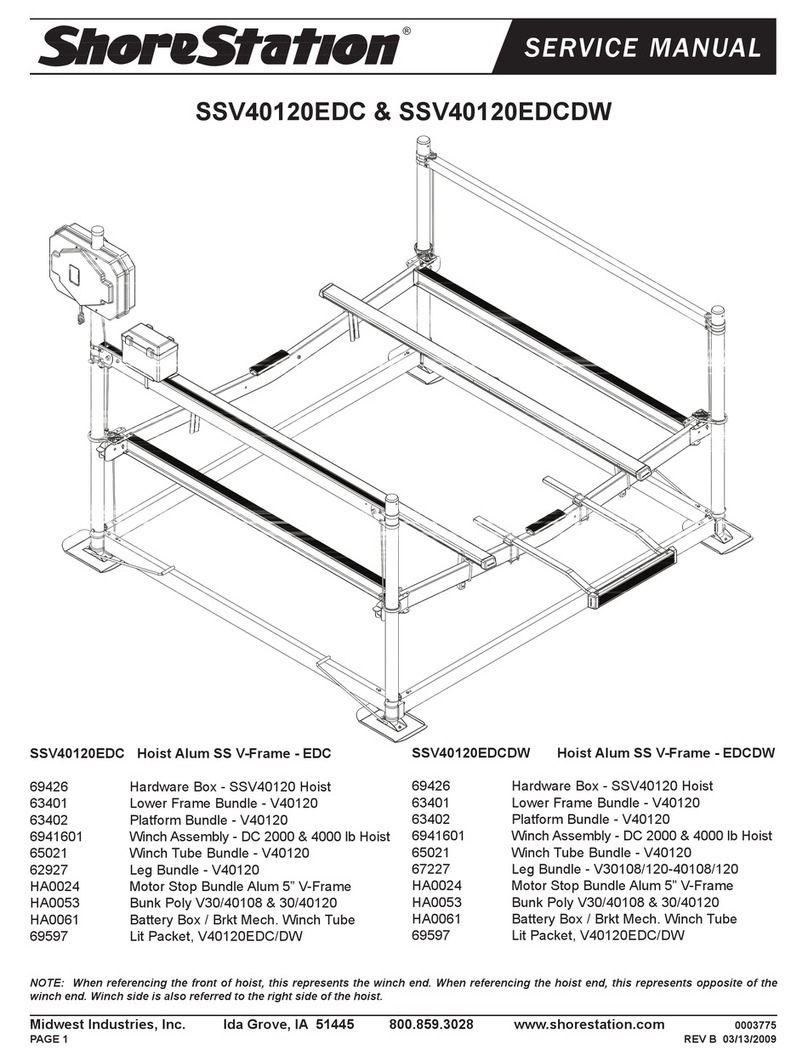

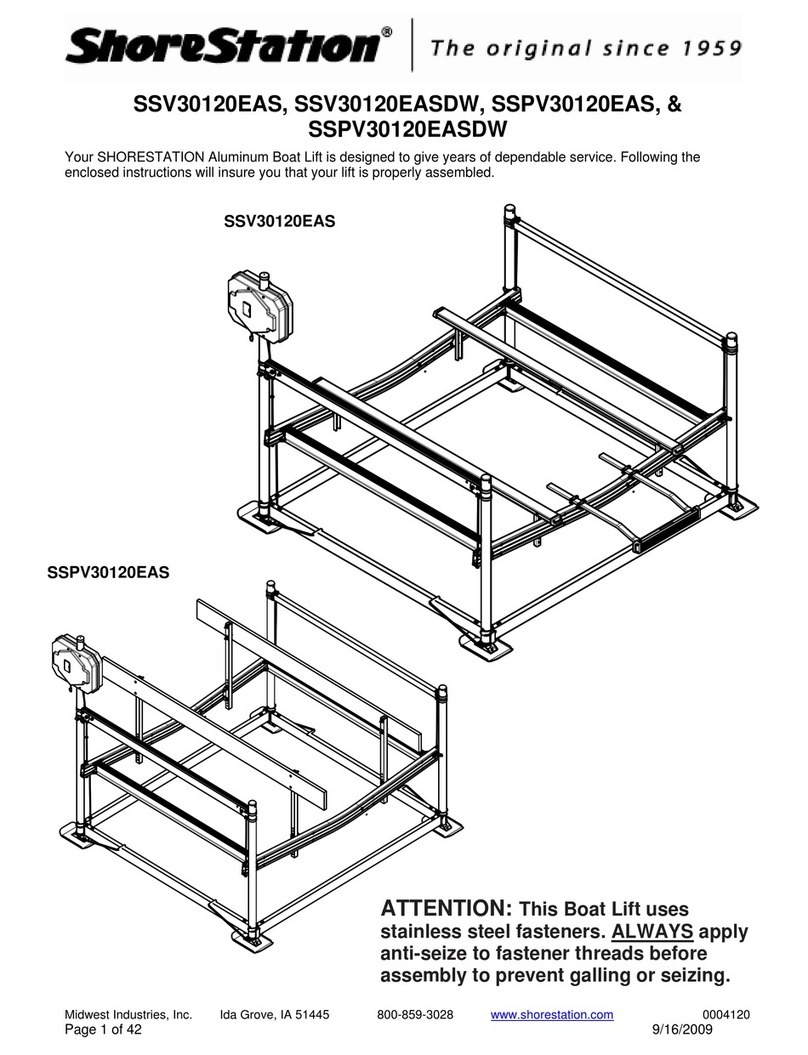

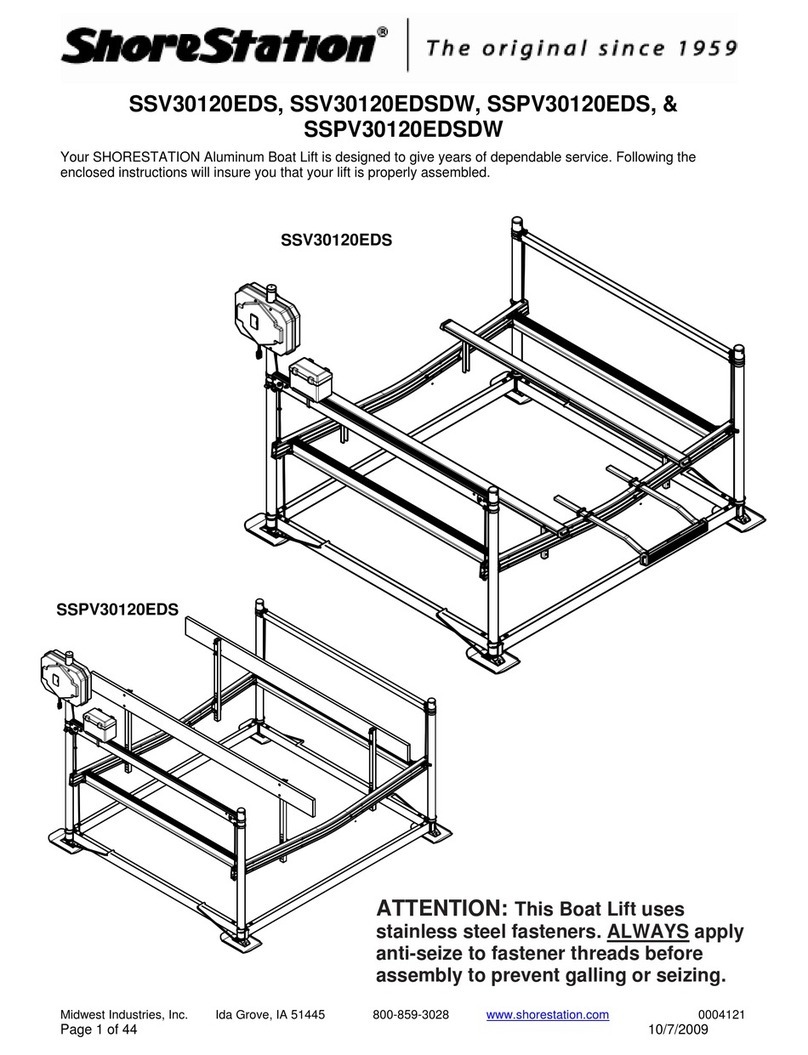

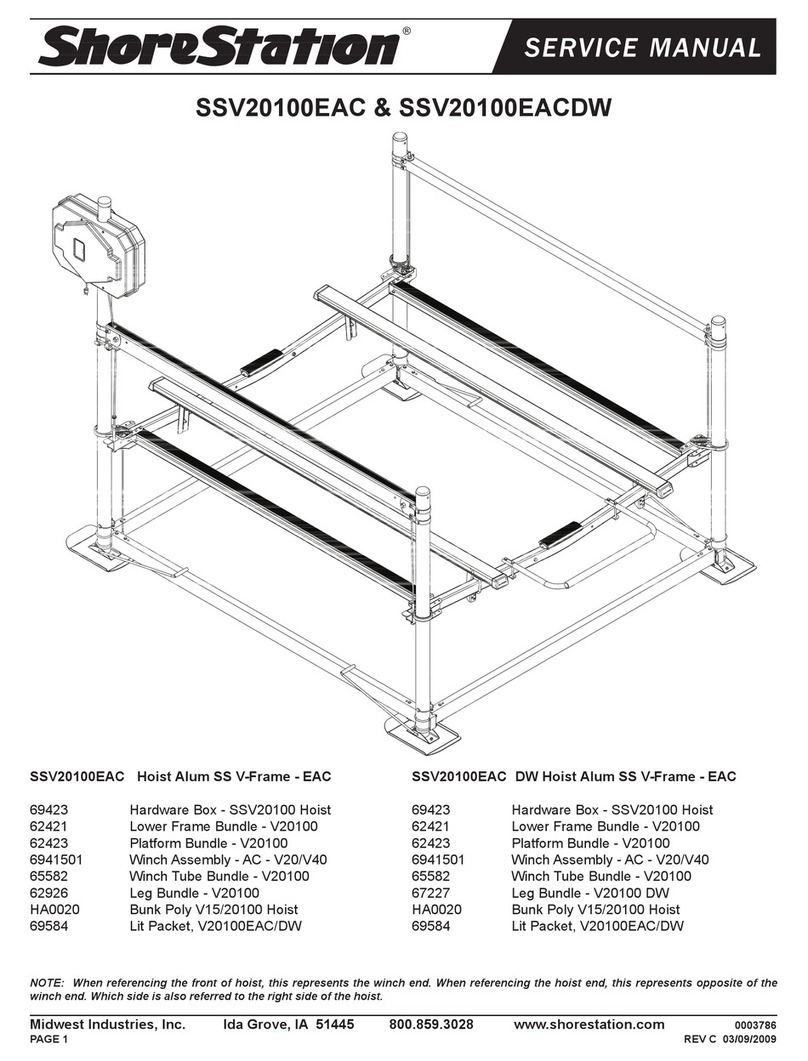

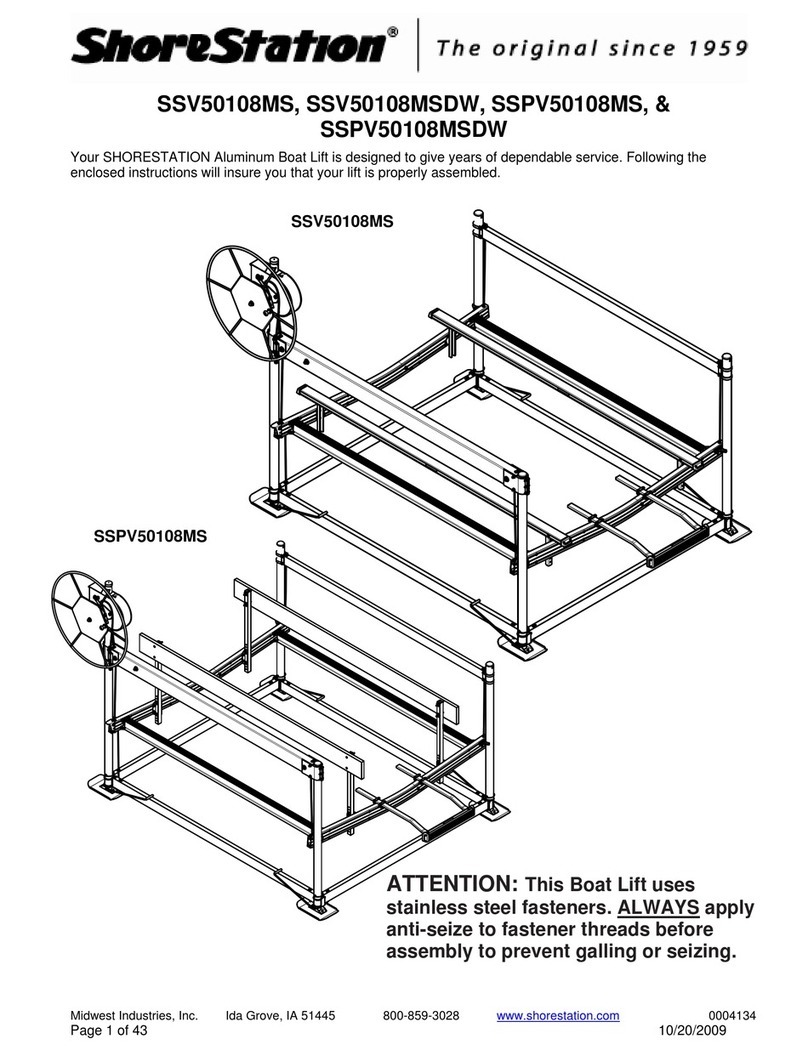

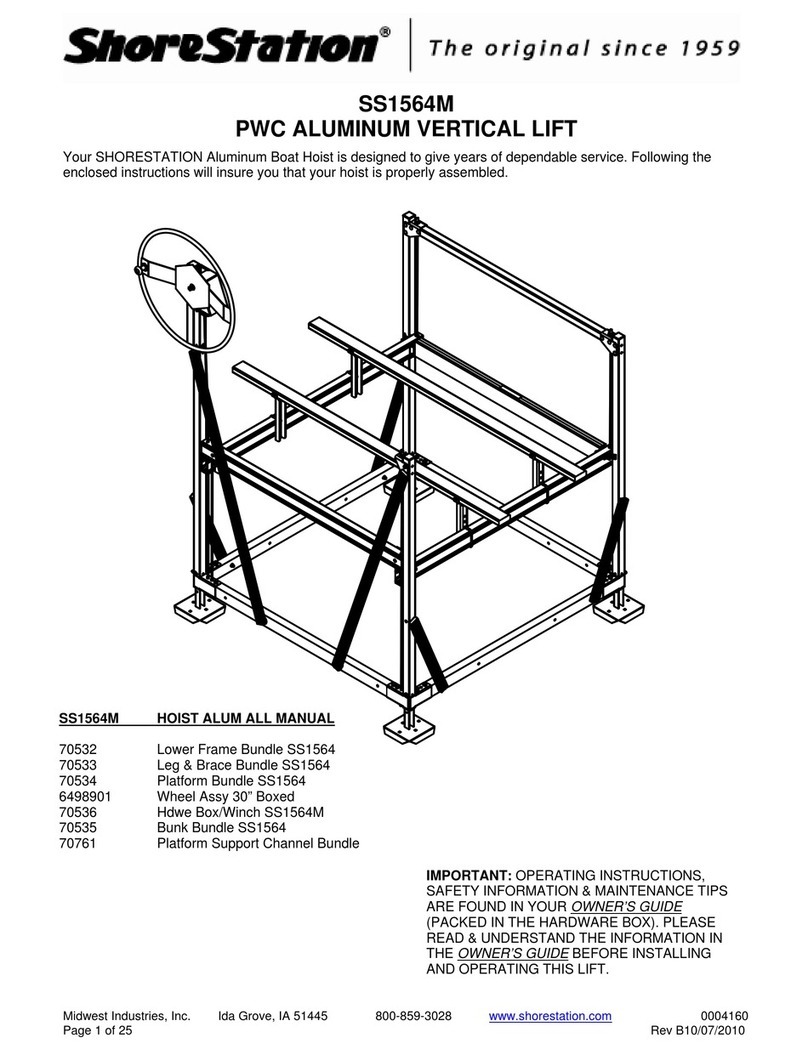

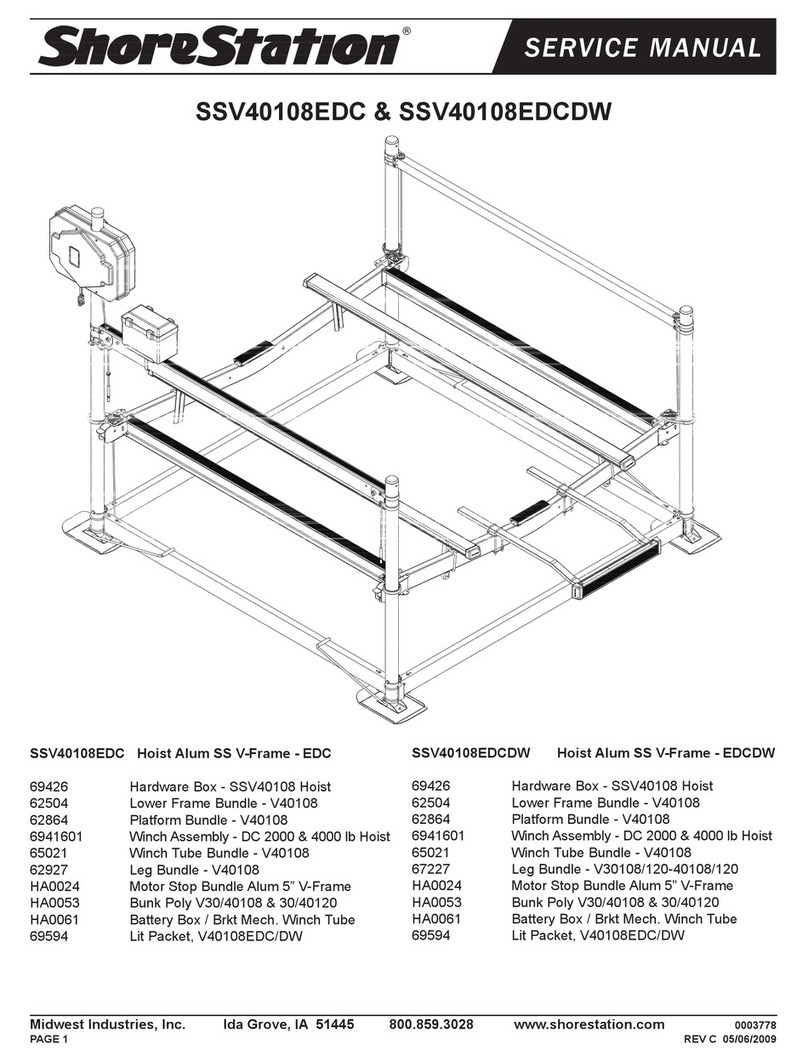

SSV40108HAC Aluminum V-Frame 4000 lb. Hydraulic Hoist with AC Drive

68681 Lower Frame Bundle

66661 Leg Bundle

68124 Hyd Lift Tube Assembly

68370 Hardware Box

68682 Platform Bundle

62512 Bunk Bundle

66659 Drop Side Bundle

67115 Hydraulic Pump Assembly - AC HYD

62513 Base Pad Bundle

SS1202 Adjustable Step - HYD Hoist

HA0001 Hoist Motor Stop Bundle - 5” Frame

67943 Leg Bundle Controller Leg - HYD

SS1204 Control Arm Assembly - HYD Hoist

SS1205 Canopy Pendant Holder - HYD Hoist

SSV40108HDC Aluminum V-Frame 4000 lb. Hydraulic Hoist with DC Drive

68681 Lower Frame Bundle

66661 Leg Bundle

68124 Hyd Lift Tube Assembly

68370 Hardware Box

68682 Platform Bundle

62512 Bunk Bundle

66659 Drop Side Bundle

66608 Hydraulic Pump Assembly - DC HYD

62513 Base Pad Bundle

SS1202 Adjustable Step - HYD Hoist

HA0001 Hoist Motor Stop Bundle - 5” Frame

67943 Leg Bundle Controller Leg - HYD

SS1204 Control Arm Assembly - HYD Hoist

SS1205 Canopy Pendant Holder - HYD Hoist

SSV40108HDAC Alum. V-Frame 4000 lb. Hyd. Deep Water Hoist w/AC Drive

68681 Lower Frame Bundle

67231 Leg Bundle - DW

68124 Hyd Lift Tube Assembly

68370 Hardware Box

68682 Platform Bundle

62512 Bunk Bundle

66659 Drop Side Bundle

67115 Hydraulic Pump Assembly - AC HYD

62513 Base Pad Bundle

SS1202 Adjustable Step - HYD Hoist

HA0001 Hoist Motor Stop Bundle - 5” Frame

67932 Leg Bundle Controller Leg - DW

SS1204 Control Arm Assembly - HYD Hoist

SS1205 Canopy Pendant Holder - HYD Hoist

SSV40108HDDC Alum. V-Frame 4000 lb. Hyd. Deep Water Hoist w/DC Drive

68681 Lower Frame Bundle

67231 Leg Bundle - DW

68124 Hyd Lift Tube Assembly

68370 Hardware Box

68682 Platform Bundle

62512 Bunk Bundle

66659 Drop Side Bundle

66608 Hydraulic Pump Assembly - DC HYD

62513 Base Pad Bundle

SS1202 Adjustable Step - HYD Hoist

HA0001 Hoist Motor Stop Bundle - 5” Frame

67932 Leg Bundle Controller Leg - DW

SS1204 Control Arm Assembly - HYD Hoist

SS1205 Canopy Pendant Holder - HYD Hoist

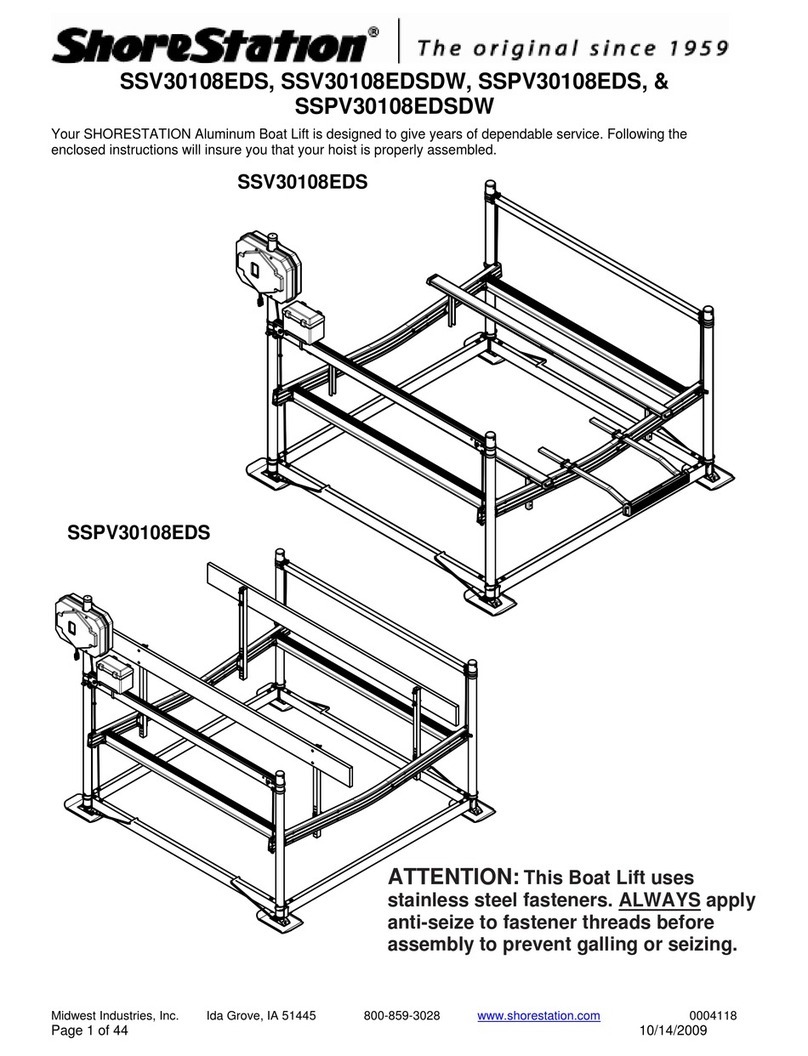

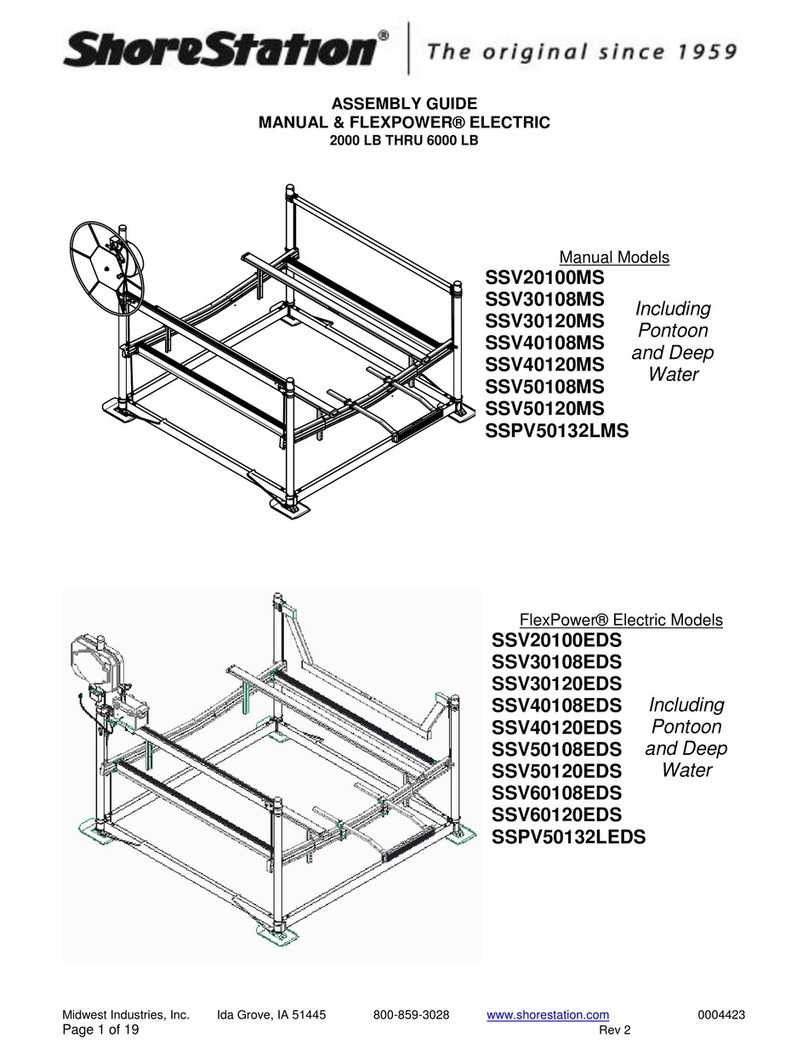

Bundles Required

Tools Required

9/16” Socket / Wrench

3/4” Socket / Wrench

5/16” Socket / Wrench

7/16” Socket / Wrench

Cable Threader

Table of Contents

Bundles Required ................................................................ 2

Tools Required .................................................................... 2

Safety Precautions .............................................................. 3

Safety Maintenance ............................................................. 3

Lower Frame Drawing (Diagram A) ..................................... 4

Lower Frame Bill of Material ................................................ 5

Base Pad Assembly ............................................................ 5

Lower Frame Assembly ....................................................... 5

Bottom Corner Cable Brackets ............................................ 5

Platform Drawing (Diagram B) ............................................ 6

Platform Bill of Material ....................................................... 7

Platform Assembly ............................................................... 7/9

Drop Side Drawing/BOM (Diagram C) ................................ 8

Drop Side Assembly ............................................................ 9

Adjustable Step Drawing/BOM (Diagram D) ....................... 9

Adjustable Step Assembly ................................................... 9

Winch Tube Drawing (Diagram E) ....................................... 10

Winch Tube Bill of Material .................................................. 11

Winch Tube Assembly ......................................................... 11

Hydraulic Pump ................................................................... 11

SS1204 - Control Arm Drawing ........................................... 12

SS1204 - Control Arm Drawing/BOM .................................. 13

SS1204 - Control Arm Assembly Instructions ...................... 13

12 Volt Pump Drawing/Assembly Instructions ..................... 14

12 Volt DC Pump Assembly Instructions ............................. 15

Hydraulic Pump Drawing ..................................................... 16

SS1203 - Battery Mounting Hardware Drawing/BOM ......... 18

SS1203 - Battery Mounting Hardware Assembly Instruct ... 18

Control Pendant Operating Instructions .............................. 19

Winch Tube Cable Diagram ................................................ 20

Connecting Lift Cables to Platform Instructions .................. 21

Replacement of Level Cables ............................................. 21

Bunk System Drawing/Assembly Instructions ..................... 22

Bunk System Installation ..................................................... 22

HA0001 - Motor Stop Kit Drawing/BOM .............................. 23

HA0001 - Motor Stop Kit Assembly Instructions .................. 23

Hydraulic Troubleshooting Guide ........................................ 24-28

General Troubleshooting - Non-Electrical ....................... 24

Oil Grade & Capacity ....................................................... 24

Oil Change Schedule/Procedures ................................... 25

Storage ............................................................................ 25

Biodegradeable Oils ........................................................ 25

Troubleshooting ............................................................... 26

AC Powered Hoists - General Elec Troubleshooting ....... 27

Wire Gauge Chart ........................................................... 27

AC Powered Pumps - Troubleshooting ........................... 27

DC Powered Pumps - Troubleshooting ........................... 28

DC Powered Hoists - General Elec Troubleshooting ...... 28