1 Safety notes

■Read the operating instructions before commissioning.

■

Connection, mounting, and setting may only be performed by skilled per‐

son.

■Not a safety component in accordance with the EU Machinery Directive.

■Power supply: Class 2

Enclosure type 1

■When commissioning, protect the device from moisture and contamination.

■These operating instructions contain information required during the life cycle of

the sensor.

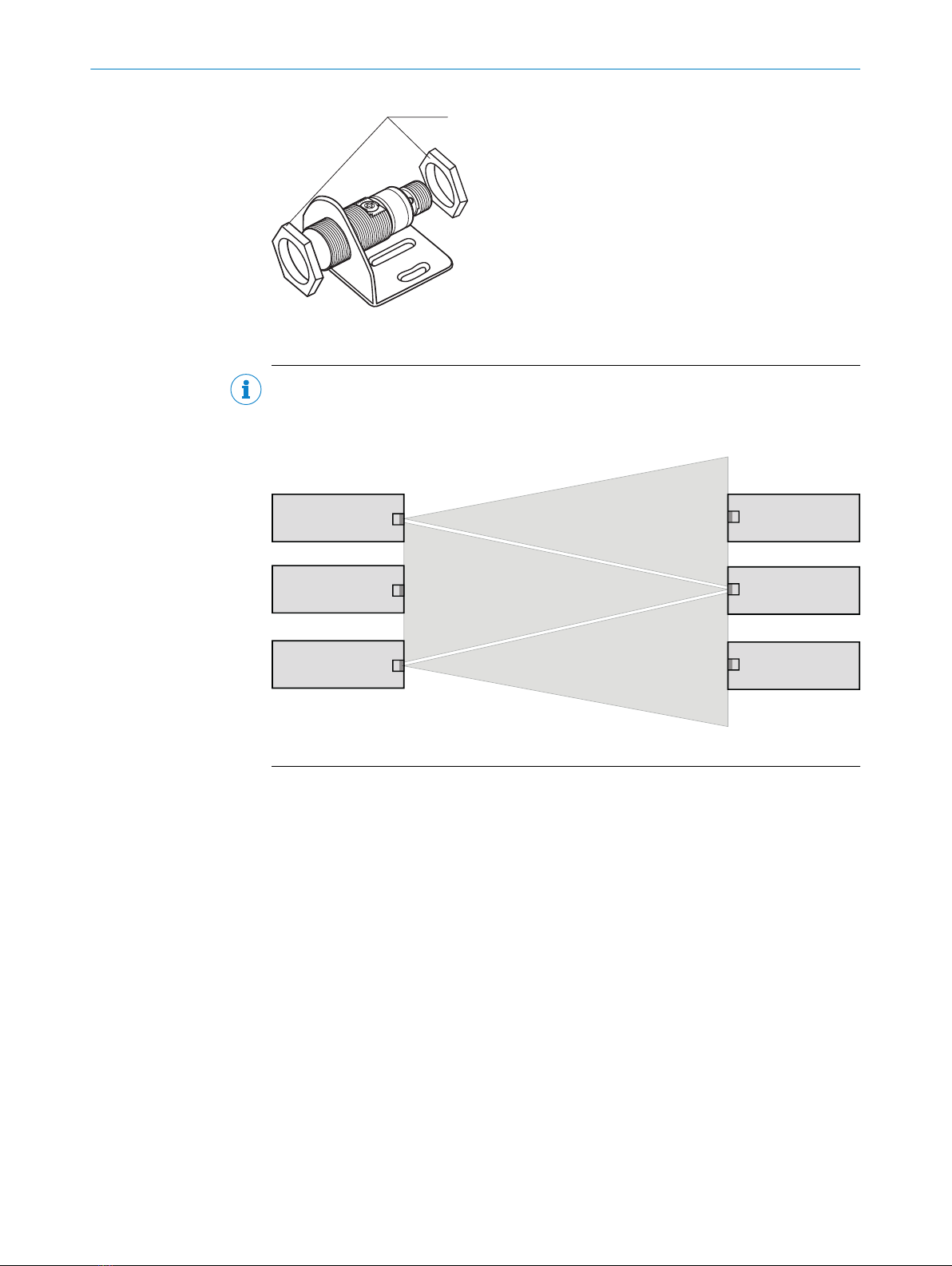

2 Intended use

The GRSE18(S)V is an opto-electronic through-beam photoelectric sensor (referred to

as “sensor” in the following) for the optical, non-contact detection of objects, animals,

and persons. A sender (WS) and a receiver (WE) are required for operation. If the prod‐

uct is used for any other purpose or modified in any way, any warranty claim against

SICK AG shall become void.

3 Operating and status indicators

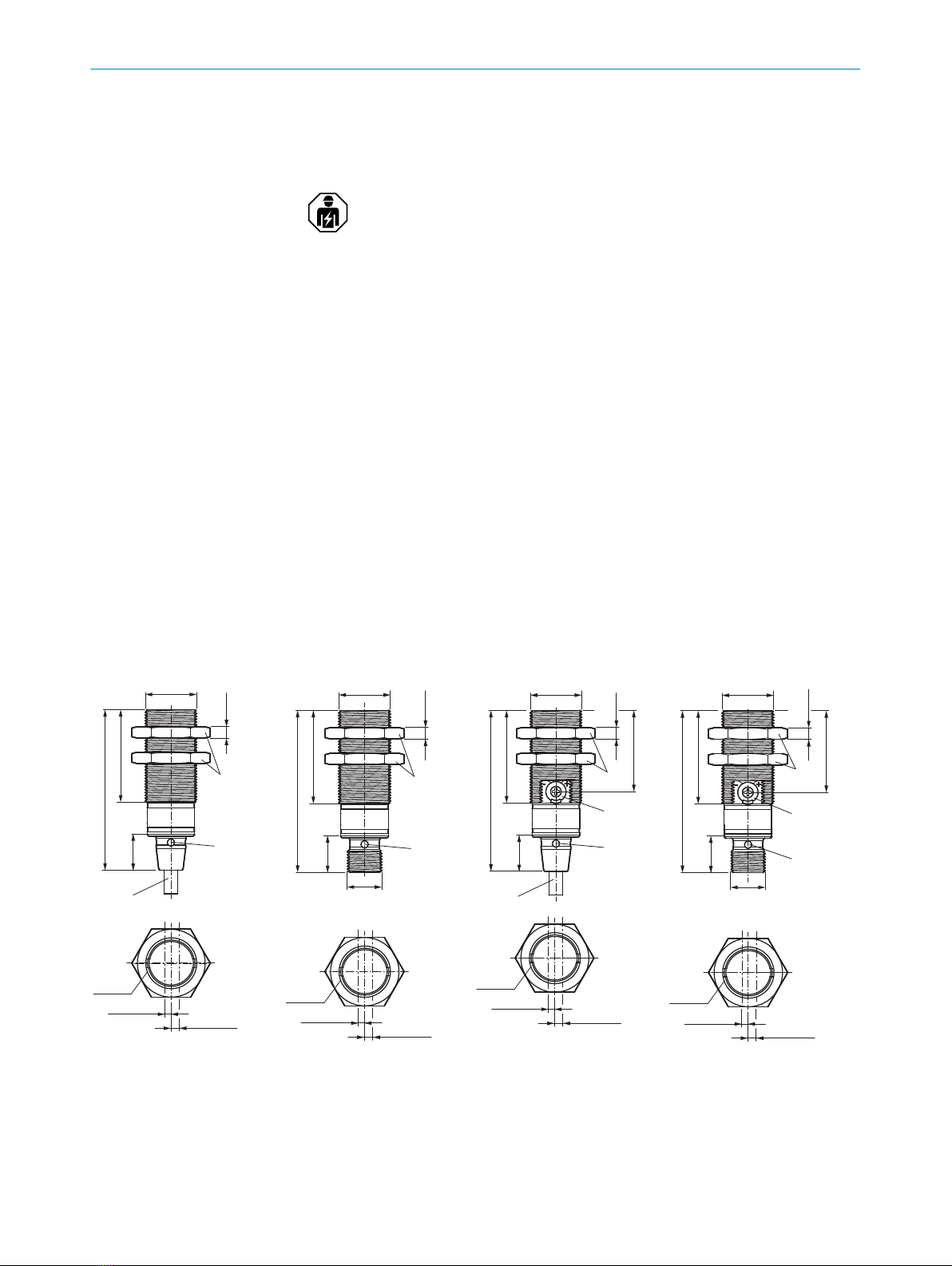

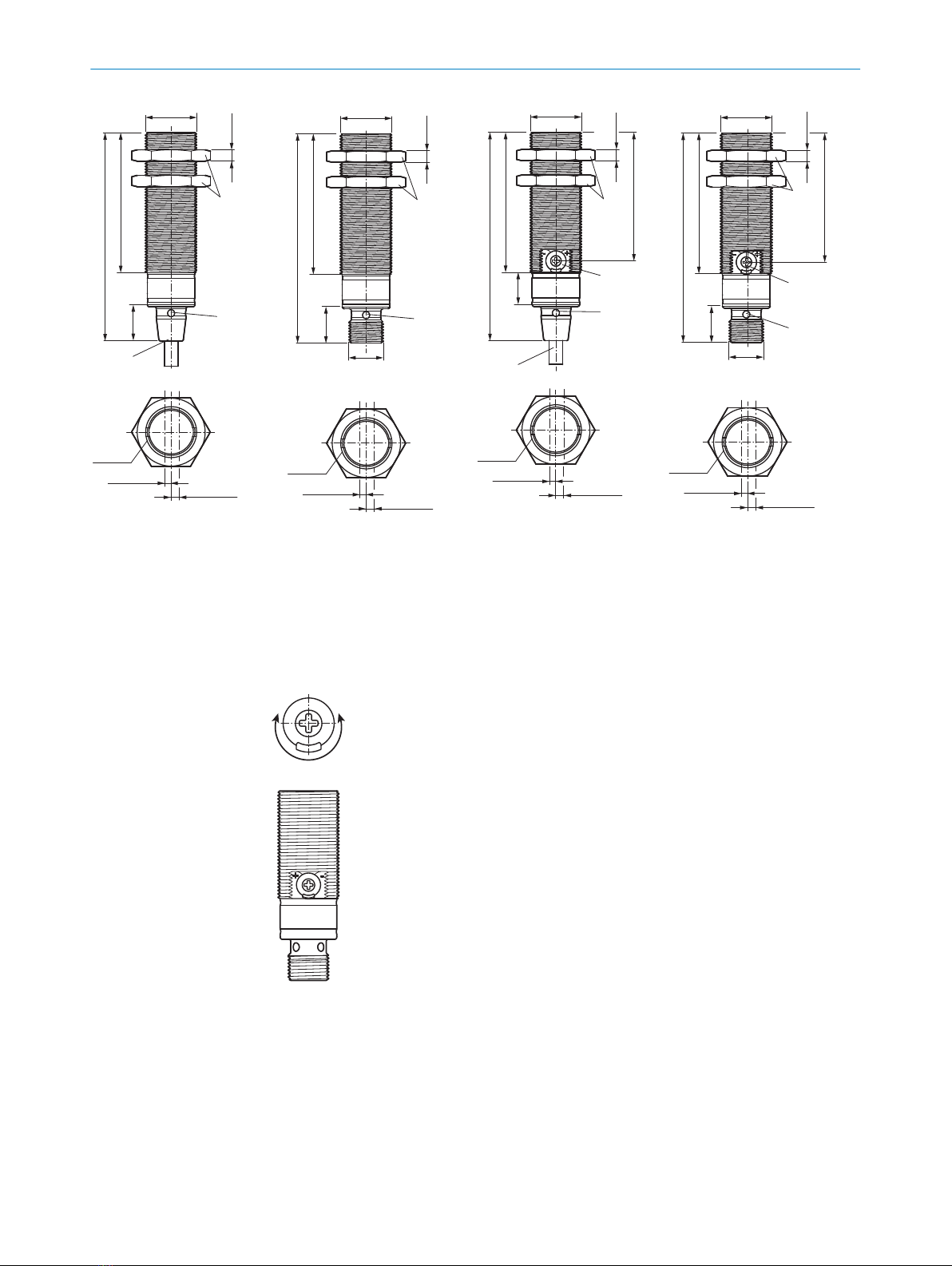

Table 1: Dimensional drawings

55.9 (2.2)

M18x1

31.7 (1.25)

4

(0.16)

12.9

(0.51)

2

2.8 (0.11)

2.2 (0.09)

3

67

5

1

M18x1

Figure 1: Short variant, con‐

necting cable

55.9 (2.2)

31.7 (1.25)

4

(0.16)

12.9

(0.51)

M12x1

M18x1

2

3

5

1

2.8 (0.11)

2.2 (0.09)

67

M18x1

Figure 2: Short variant, M12

male connector

27.8 (1.09)

55.9 (2.2)

31.7 (1.25)12.9

(0.51)

4

(0.16)

M18x1

2

3

4

5

1

2.8 (0.11)

2.2 (0.09)

67

M18x1

Figure 3: Short variant, potenti‐

ometer, connecting cable

12.9

(0.51)

4

(0.16)

55.9 (2.2)

31.7 (1.25)

27.8 (1.09)

M12x1

M18x1

2

3

4

5

1

2.8 (0.11)

2.2 (0.09)

67

M18x1

Figure 4: Short variant, potenti‐

ometer, M12 male connector

SAFETY NOTES 1

8021182 | SICK

Subject to change without notice 5