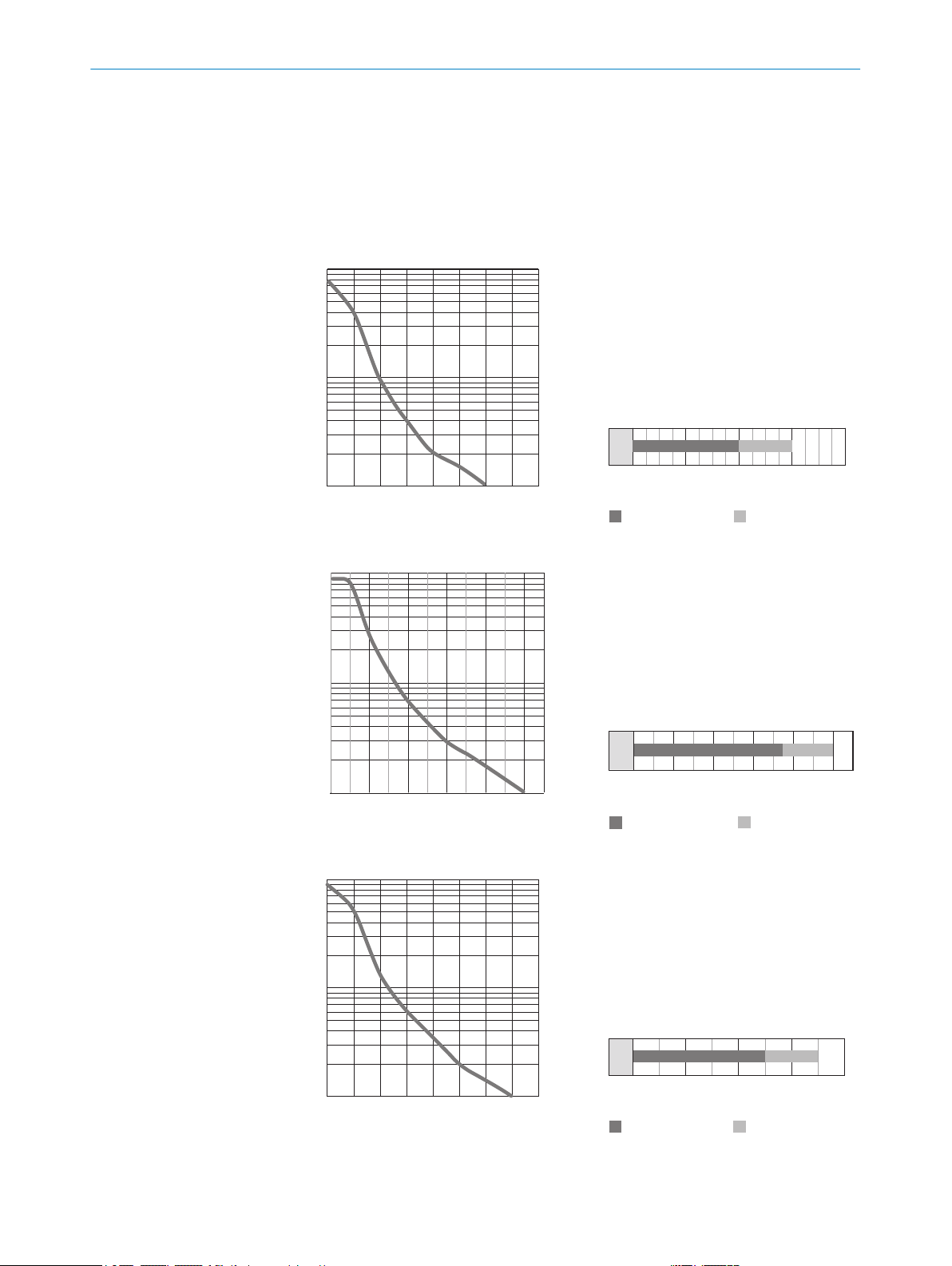

Figure 9: Sensing range area

Use see table 3, page 8 to check the function. If the switching output fails to behave in

accordance with the table, check the application conditions. See section Fault diagnosis.

3Sensitivity setting

Sensor which it is not possible to set: The sensor is adjusted and ready for operation.

8 Troubleshooting

The Troubleshooting table indicates measures to be taken if the sensor stops working.

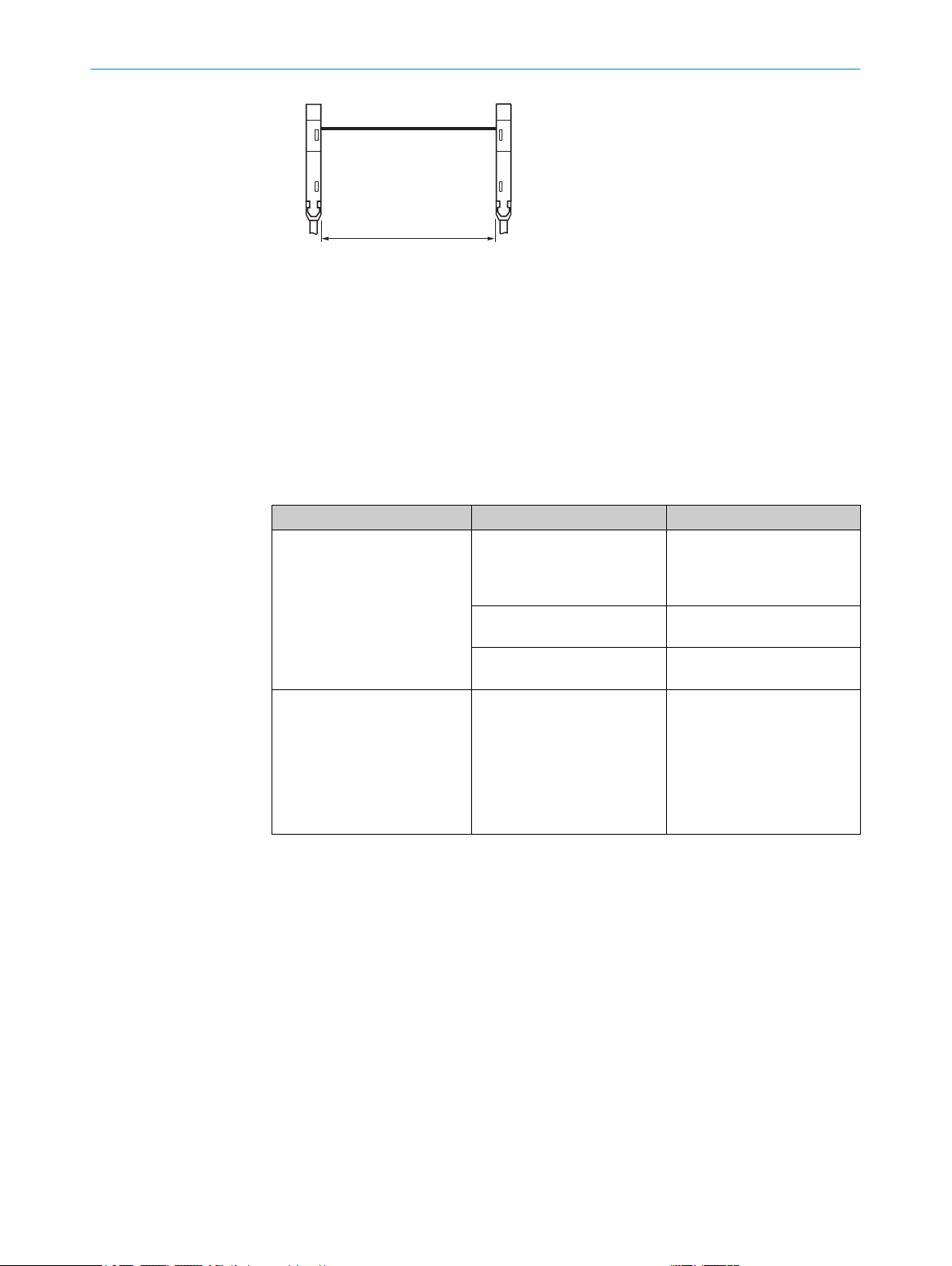

Table 4: Troubleshooting

LED indicator/fault pattern Cause Measures

Yellow LED does not light up

even though the light beam is

aligned to the receiver and

there is no object in the path of

the beam

No voltage or voltage below

the limit values

Check the power supply,

check all electrical connec‐

tions (cables and plug connec‐

tions)

Voltage interruptions Ensure there is a stable power

supply without interruptions

Sensor is faulty If the power supply is OK,

replace the sensor

Yellow LED lights up, no object

in the path of the beam

The beam of light of a photo‐

electric through-beam sensor

hits the receiver of another

(neighboring) photoelectric

through-beam sensor

Swap the sender and receiver

arrangement at every sec‐

ond through-beam photoelec‐

tric sensor and ensure that

there is sufficient distance

between the through-beam

photoelectric sensors, see

figure 1, page 6

9 Disassembly and disposal

The sensor must be disposed of according to the applicable country-specific regula‐

tions. Efforts should be made during the disposal process to recycle the constituent

materials (particularly precious metals).

8 TROUBLESHOOTING

10 8023329 | SICK

Subject to change without notice