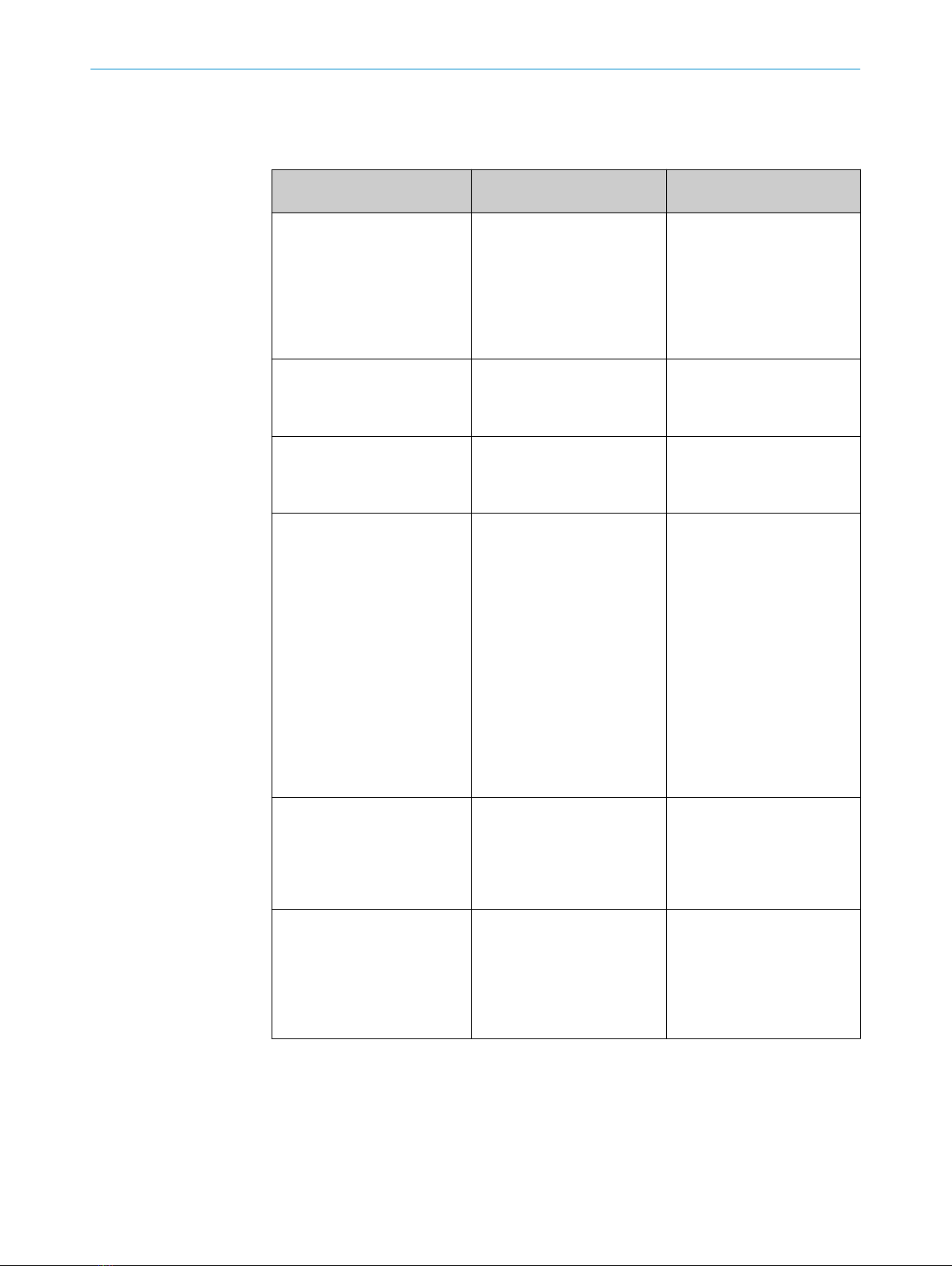

15 Tabelle Fehlerdiagnose

Anzeige-LED / Fehlerbild /

LED indicator/fault pattern

Ursache /

Cause

Maßnahme /

Measures

grüne LED leuchtet nicht /

Green LED does not light up

keine Spannung oder Span‐

nung unterhalb der Grenz‐

werte /

No voltage or voltage below

the limit values

Spannungsversorgung prüfen,

den gesamten elektrischen

Anschluss prüfen (Leitungen

und Steckerverbindungen) /

Check the power supply,

check all electrical connecti‐

ons (cables and plug connecti‐

ons)

grüne LED leuchtet nicht /

Green LED does not light up

Spannungsunterbrechungen /

Voltage interruptions

Sicherstellen einer stabilen

Spannungsversorgung ohne

Unterbrechungen /

Ensure there is a stable power

supply without interruptions

grüne LED leuchtet nicht /

Green LED does not light up

Sensor ist defekt /

Sensor is faulty

Wenn Spannungsversorgung

in Ordnung ist, dann Sensor

austauschen /

If the power supply is OK,

replace the sensor

gelbe LED blinkt /

Yellow LED flashes

Sensor ist noch betriebsbe‐

reit, aber die Betriebsbedin‐

gungen sind nicht optimal /

Sensor is still ready for opera‐

tion, but the operating conditi‐

ons are not ideal

Betriebsbedingungen prüfen:

Lichtstrahl (Lichtfleck) voll‐

ständig auf das Objekt aus‐

richten / Reinigung der opti‐

schen Flächen / Empfindlich‐

keit neu einstellen / Schaltab‐

stand überprüfen und ggf.

anpassen, siehe Grafik F. /

Check the operating conditi‐

ons: Fully align the beam of

light (light spot) with the

object. / Clean the optical sur‐

faces . / Readjust the sensiti‐

vity / Check sensing range

and adjust if necessary; see

graphic F.

gelbe LED leuchtet, kein Objekt

im Strahlengang /

Yellow LED lights up, no object

in the path of the beam

Abstand zwischen Sensor und

Hintergrund ist zu gering /

/ Distance between the sen‐

sor and the background is too

short

Schaltabstand verringern,

siehe Grafik F /

Reduce the sensing range,

see graphic F

Objekt ist im Strahlengang,

gelbe LED leuchtet nicht /

Object is in the path of the

beam, yellow LED does not

light up

Abstand zwischen Sensor und

Objekt ist zu groß oder Schalt‐

abstand ist zu gering einge‐

stellt /

Distance between the sensor

and the object is too long or

sensing range is set too short

Schaltabstand vergrößern,

siehe Grafik F /

Increase the sensing range,

see graphic F

16 Demontage und Entsorgung

Die Entsorgung des Sensors hat gemäß den länderspezifisch anwendbaren Vorschrif‐

ten zu erfolgen. Für die enthaltenen Wertstoffe (insbesondere Edelmetalle) ist im Rah‐

men der Entsorgung eine Verwertung anzustreben.

TABELLE FEHLERDIAGNOSE 15

7

8019200.126R | SICK

Subject to change without notice