4.4.5 IO-Link...................................................................................... 40

4.4.6 Muting....................................................................................... 41

4.4.7 Connection diagrams.............................................................. 42

4.5 Testing plan............................................................................................... 46

4.5.1 Test rod check.......................................................................... 46

4.5.2 Visual check of the machine and the protective device........ 48

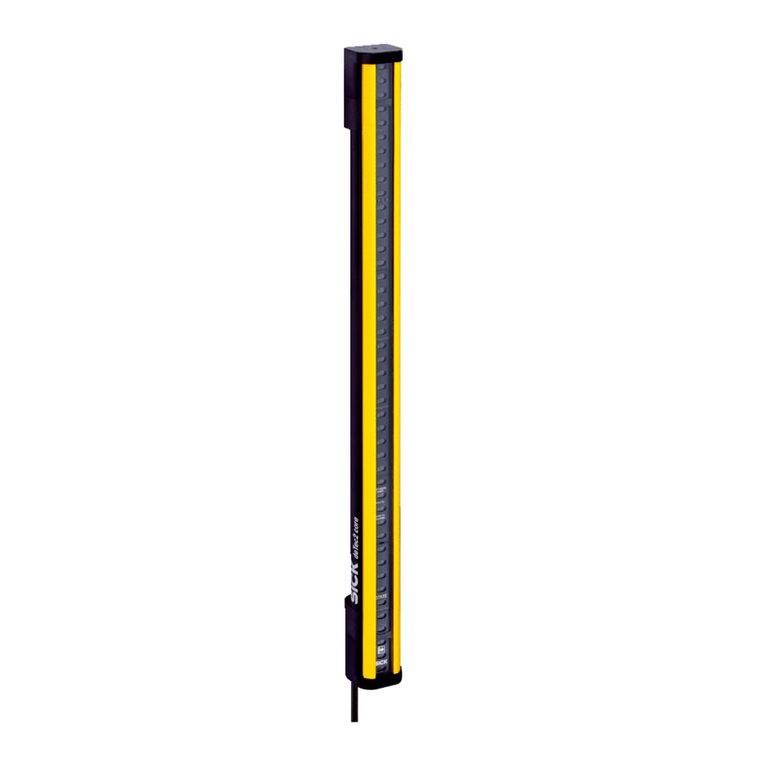

5 Mounting............................................................................................. 49

5.1 Safety......................................................................................................... 49

5.2 Unpacking.................................................................................................. 49

5.3 Fitting the system plug............................................................................. 50

5.4 Mounting................................................................................................... 51

5.4.1 Mounting the QuickFix bracket............................................... 54

5.4.2 Mounting the FlexFix bracket.................................................. 55

6 Electrical installation........................................................................ 60

6.1 Safety......................................................................................................... 60

6.2 System connection (M12, 5-pin)............................................................. 62

6.3 System connection (M12, 8-pin)............................................................. 62

6.4 Extension connection (M12, 5-pin)......................................................... 63

7 Configuration..................................................................................... 65

7.1 Overview.................................................................................................... 65

7.2 Factory settings......................................................................................... 66

7.2.1 Set to factory settings............................................................. 67

7.3 Configuration mode.................................................................................. 67

7.4 Configuring beam coding......................................................................... 68

7.5 Configuring muting................................................................................... 69

7.6 Checking the parity................................................................................... 70

7.7 Configuring the restart interlock.............................................................. 71

7.8 Configuring external device monitoring (EDM)....................................... 72

7.9 Configuring application diagnostic output.............................................. 72

8 Commissioning.................................................................................. 74

8.1 Safety......................................................................................................... 74

8.2 Overview.................................................................................................... 74

8.3 Switching on.............................................................................................. 75

8.4 Alignment of the active and passive units.............................................. 75

8.4.1 Aligning the active and passive units..................................... 76

8.4.2 Alignment with the QuickFix bracket...................................... 76

8.4.3 Alignment with the FlexFix bracket or with the replacement

bracket...................................................................................... 77

8.4.4 Indication of the alignment quality......................................... 78

8.5 Check during commissioning and modifications.................................... 79

9 Operation............................................................................................ 80

9.1 Overview.................................................................................................... 80

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | deTem4 A/P 8024782/2019-11-19 | SICK

Subject to change without notice