4.3.7 Requirements for the reset pushbutton and restart button. 31

4.4 Integrating the equipment into the electrical control............................. 31

4.4.1 Circuit diagram......................................................................... 31

4.5 Integration into the network..................................................................... 31

4.5.1 Interfaces................................................................................. 31

4.6 Testing plan............................................................................................... 33

5 Mounting............................................................................................. 34

5.1 For mounting the components................................................................. 34

6 Electrical installation........................................................................ 35

6.1 Electrical installation of the components................................................ 35

6.2 General requirements.............................................................................. 35

6.3 Safety controller pin assignment............................................................. 35

7 Configuration..................................................................................... 38

7.1 Requirements for software and firmware............................................... 38

7.2 Pre-configured project files...................................................................... 38

7.3 Overview of the software structure.......................................................... 39

7.4 Opening project file................................................................................... 40

7.5 Connection overview................................................................................ 41

7.6 Main module configuration...................................................................... 41

7.6.1 Verifying the logic..................................................................... 41

7.6.2 Jump addresses....................................................................... 41

7.6.2.1 Finding source and destination jump addresses

that belong together............................................... 41

7.6.3 In/out page.............................................................................. 41

7.6.4 Emergency stop page.............................................................. 42

7.6.5 Protective stop page................................................................ 42

7.6.6 SafetyRatedMonitoredSpeed page......................................... 43

7.6.7 SafeSequenceMonitoring page............................................... 43

7.6.8 Robot safety signals page....................................................... 44

7.6.9 Non-secure robot signals page............................................... 45

7.7 Configuring the safety laser scanner....................................................... 45

7.7.1 Resolution of the safety laser scanner................................... 45

7.7.2 Field sets and cut-off paths.................................................... 45

7.7.3 Configuring the safety system without protective field PF3.. 46

7.8 Transfer configuration.............................................................................. 46

8 Commissioning.................................................................................. 47

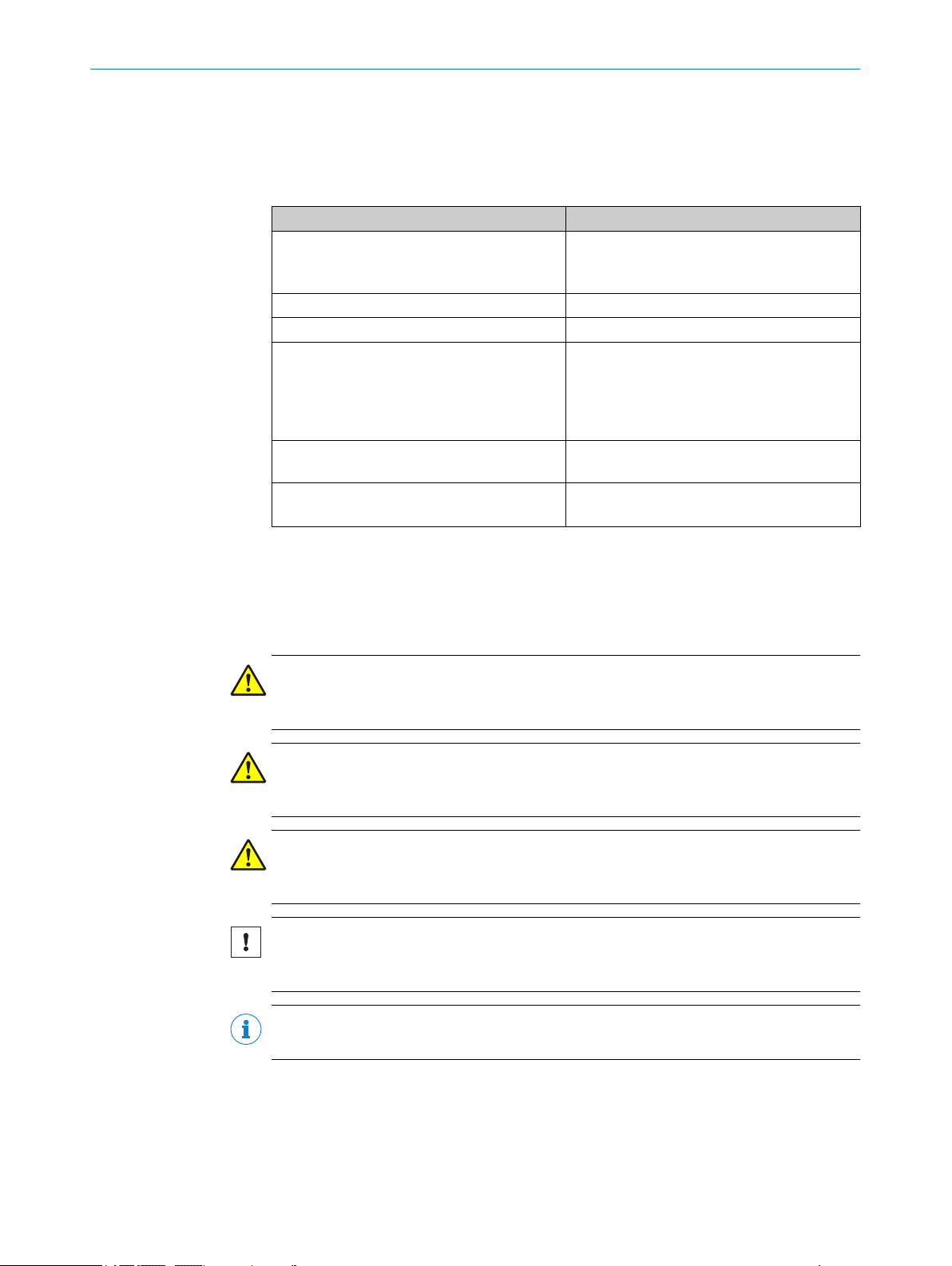

8.1 Safety......................................................................................................... 47

8.2 Overview of commissioning..................................................................... 47

8.3 Putting the robot controller into operation.............................................. 48

8.3.1 Configuring the IP address of the robot controller on the

smartPAD................................................................................. 48

8.3.2 Configuring the non-safe signals on the smartPAD............... 49

8.3.3 Preparing the project in KUKA.WorkVisual............................. 50

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | sBot Speed CIP – KU 8024758/2020-02-20 | SICK

Subject to change without notice