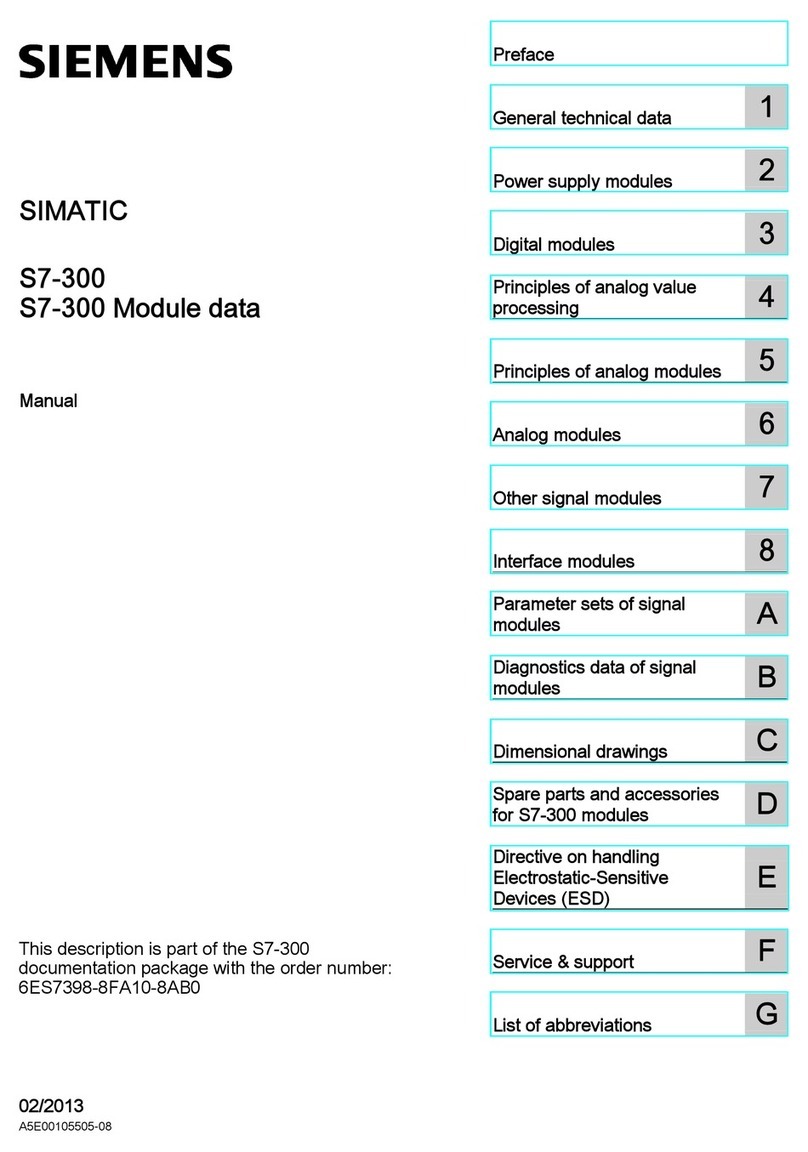

Table of contents

Turning

Operating Manual, 07/2010, 6FC5398-8CP40-0BA0 9

4.7.2 Continuing program from search target .....................................................................................119

4.7.3 Simple search target definition...................................................................................................119

4.7.4 Defining an interruption point as search target..........................................................................120

4.7.5 Entering the search target via search pointer ............................................................................121

4.7.6 Parameters for block search in the search pointer ....................................................................122

4.7.7 Block search mode ....................................................................................................................123

4.8 Intervening in the program sequence ........................................................................................125

4.8.1 Program control..........................................................................................................................125

4.8.2 Skip blocks.................................................................................................................................127

4.9 Overstore ...................................................................................................................................129

4.10 Editing a program.......................................................................................................................131

4.10.1 Searching in programs...............................................................................................................131

4.10.2 Exchanging program text...........................................................................................................133

4.10.3 Copying/pasting/deleting a program block.................................................................................134

4.10.4 Renumbering a program............................................................................................................135

4.10.5 Opening a second program .......................................................................................................136

4.10.6 Editor settings ............................................................................................................................137

4.11 Displaying G functions and auxiliary functions ..........................................................................139

4.11.1 Selected G functions..................................................................................................................139

4.11.2 All G functions............................................................................................................................141

4.11.3 Auxiliary functions ......................................................................................................................142

4.12 Displaying the program runtime and counting workpieces........................................................145

4.13 Setting for automatic mode........................................................................................................147

5 Simulating a machining operation.......................................................................................................... 149

5.1 Overview ....................................................................................................................................149

5.2 Simulation before machining of the workpiece ..........................................................................153

5.3 Simultaneous recording before machining of the workpiece.....................................................155

5.4 Simultaneous recording during machining of the workpiece .....................................................156

5.5 Different views of a workpiece ...................................................................................................157

5.5.1 Side view....................................................................................................................................157

5.5.2 Half section ................................................................................................................................157

5.5.3 Face view...................................................................................................................................158

5.5.4 3D view ......................................................................................................................................158

5.5.5 2-window....................................................................................................................................159

5.6 Graphical display .......................................................................................................................160

5.7 Editing the simulation display.....................................................................................................161

5.7.1 Entering blank details.................................................................................................................161

5.7.2 Showing and hiding the tool path...............................................................................................161

5.8 Program control during the simulation.......................................................................................162

5.8.1 Changing the feedrate ...............................................................................................................162

5.8.2 Simulating the program block by block ......................................................................................163

5.9 Editing and adapting a simulation graphic.................................................................................164

5.9.1 Enlarging or reducing the graphical representation...................................................................164

5.9.2 Panning a graphical representation ...........................................................................................165

5.9.3 Rotating the graphical representation........................................................................................165

5.9.4 Modifying the viewport ...............................................................................................................166

5.9.5 Defining cutting planes...............................................................................................................167