iv C7-621 / C7-621 AS-i Control Systems

C79000-G7076-C622-01

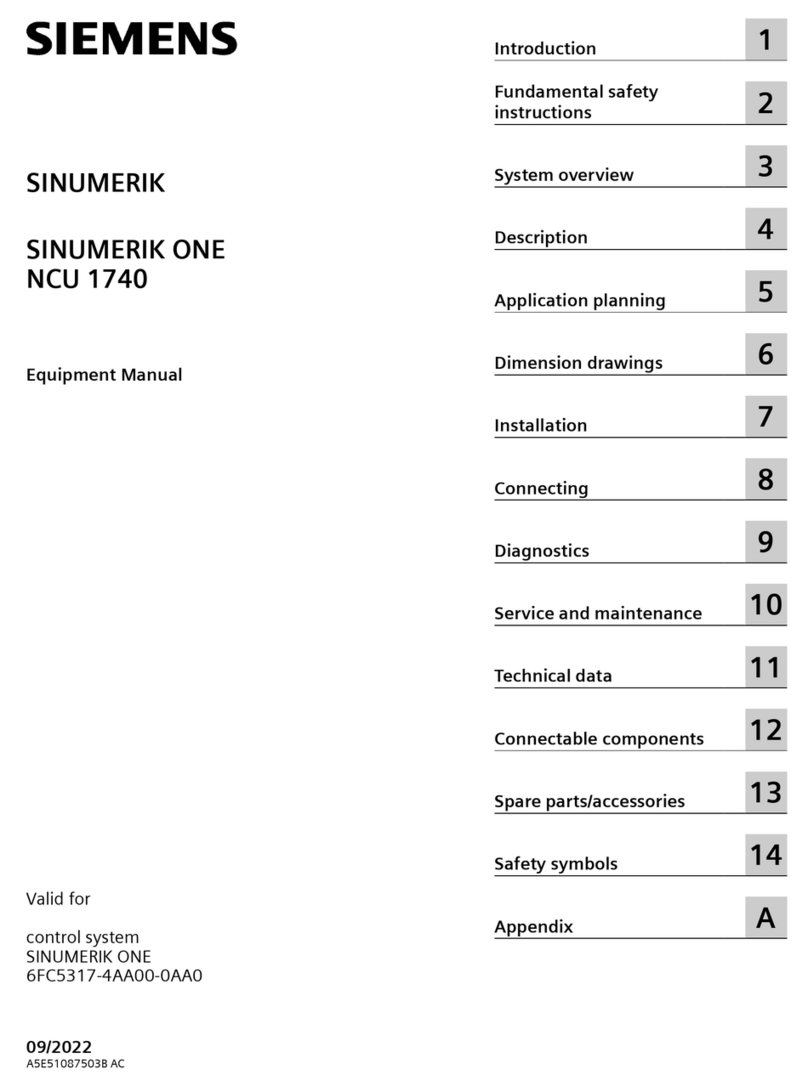

4 Addressing, Parameter Assignment, and Functions of the C7 I/Os 4-1. . . . . . . . . .

4.1 Slot-Oriented Address Assignment for Signal Modules 4-2. . . . . . . . . . . . . . . .

4.2 Addressing the C7 Digital I/Os 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Use and Functions of the C7 Analog I/Os 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Addressing Analog I/Os 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Analog Value Representation 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Analog Value Representation for the Measuring Ranges of the

Analog Inputs 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 Analog Value Representation for the Output Range of the

Analog Outputs 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Examples of Programming the Analog I/Os 4-11. . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Block for Scaling Analog Output Values 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Block for Scaling Analog Input Values 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Introduction to AS-i 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Introduction 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 AS-i System Concept 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 System Characteristics and Important Data 5-7. . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 The C7-AS-i CP for C7-621 AS-i 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Further AS-i System Components 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 The AS-i Cable 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 AS-i Modules 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 AS-i Repeater / Extender 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.4 Sensors/Actuators with an Integrated AS-i Connection 5-14. . . . . . . . . . . . . . . .

5.5 The Master Mode - Commands, Sequence, Programming 5-15. . . . . . . . . . . . .

5.5.1 Operating Phases and Functions 5-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 AS-i Application and Functions 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 AS-i Application and Functions 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Standard Operation 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Configuring the C7 AS-i CP for Standard Operation 6-3. . . . . . . . . . . . . . . . . .

6.2.2 Addressing the C7 AS-i CP with a Program 6-5. . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Control and Display Elements of the C7-621 AS-i 6-10. . . . . . . . . . . . . . . . . . . .

6.3.1 Setting the Configuration or Protected Mode 6-14. . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Setting the Address of a Slave 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Setting the AUTOPROG Mode 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.4 Replacing a Defective Slave and Automatic Address Programming

(AUTOPROG) 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.5 Setting the Desired Configuration from the Actual Configuration 6-22. . . . . . . .

6.3.6 Status of the Slaves 6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.7 Status and Error Messages of the Master 6-26. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Error Indicators on the C7 AS-i CP / How to Remedy Errors 6-27. . . . . . . . . . .

6.4.1 Diagnostics and Response to Interrupts of the C7 AS-i CP 6-28. . . . . . . . . . . .

6.5 Extended Operation with FC AS-i_3422 6-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Interface for C7 AS-i CP Commands 6-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 AS-i Cycle Time and Number of Connected Slaves 6-60. . . . . . . . . . . . . . . . . . .

Contents