INDICE

USE OF THE MANUAL....................................................................................................................... 1

GLOSSARY SYMBOLS-TERMINOLOGY........................................................................................... 2

GENERAL WARNINGS....................................................................................................................... 4

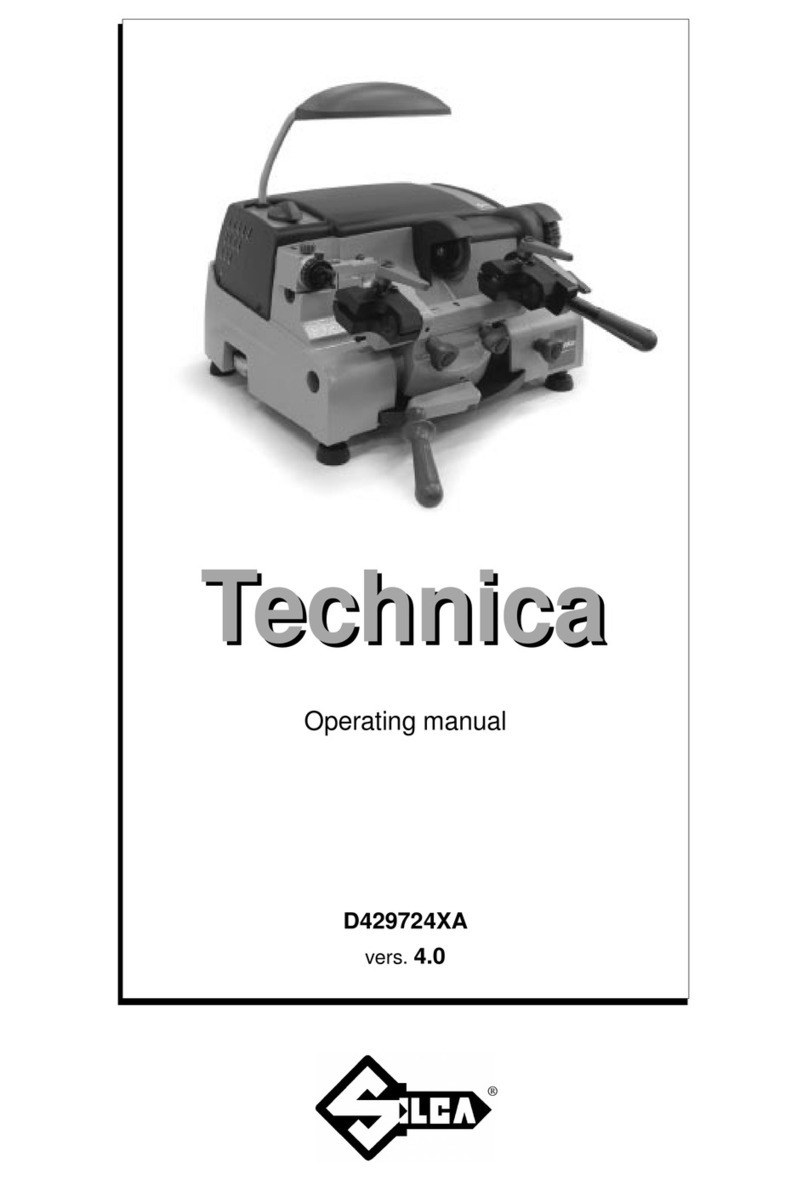

1 MACHINE DESCRIPTION....................................................................................................................5

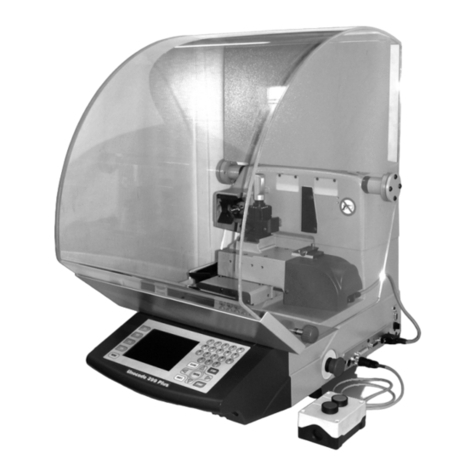

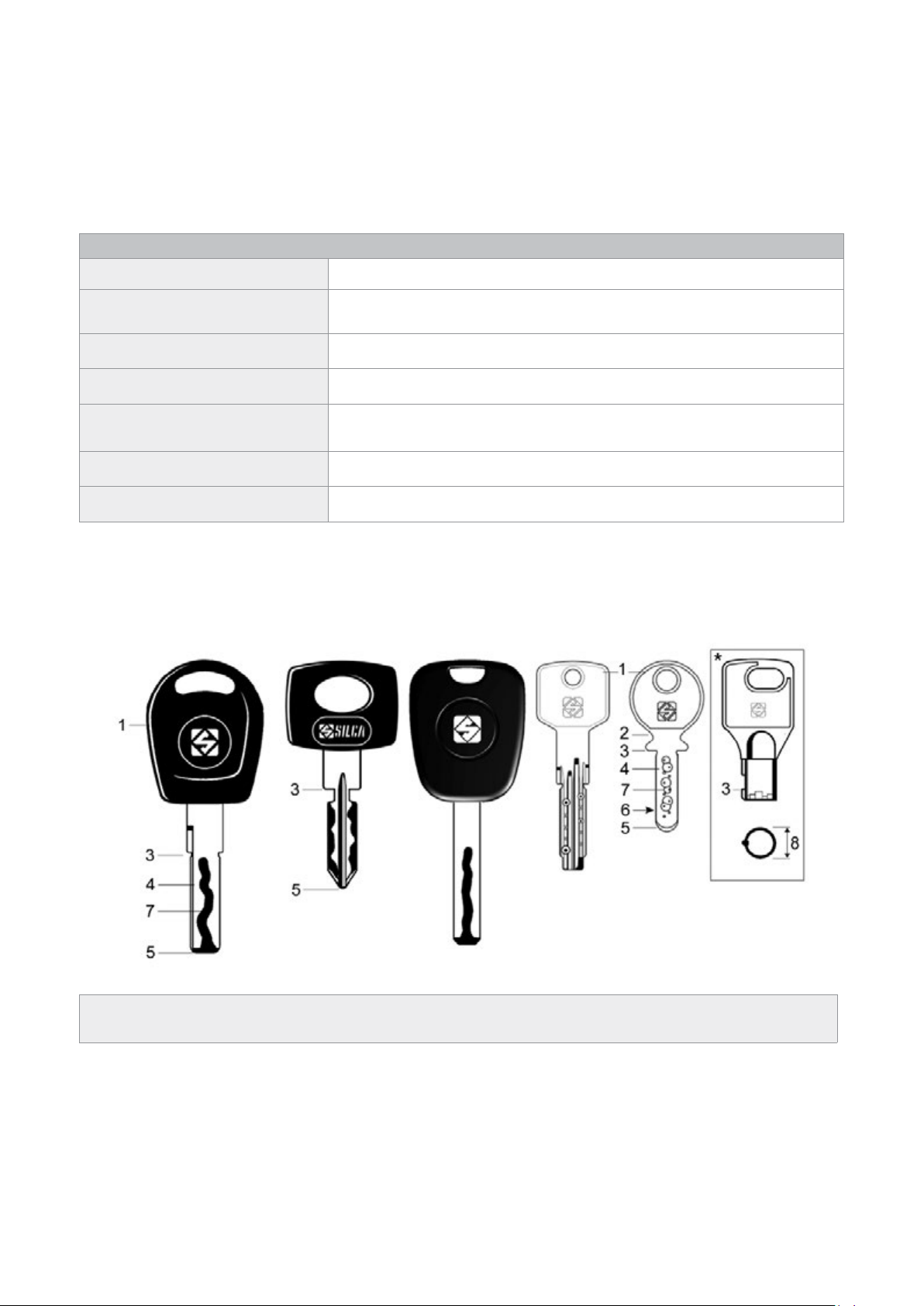

2 WORKING PARTS - Matrix PRO..........................................................................................................6

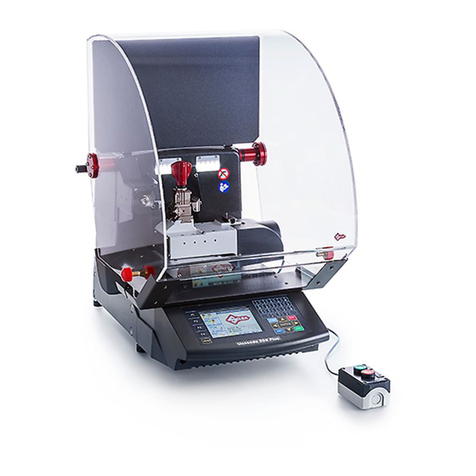

3 WORKING PARTS - Matrix EVO..........................................................................................................7

4 ACCESSORIES PROVIDED ................................................................................................................8

4.1 Technical data ...................................................................................................................................8

5 ELECTRIC DIAGRAM .........................................................................................................................9

6 HANDLING .........................................................................................................................................10

6.1 Packing...........................................................................................................................................10

6.2 Transport ........................................................................................................................................10

6.3 Unpacking.......................................................................................................................................10

6.4 Handling the machine.....................................................................................................................10

7 MACHINE INSTALLATION AND PREPARATION ..............................................................................11

7.1 Checking for damage ..................................................................................................................... 11

7.2 Environmental conditions ............................................................................................................... 11

7.3 Positioning...................................................................................................................................... 11

7.4 Safety devices ................................................................................................................................ 11

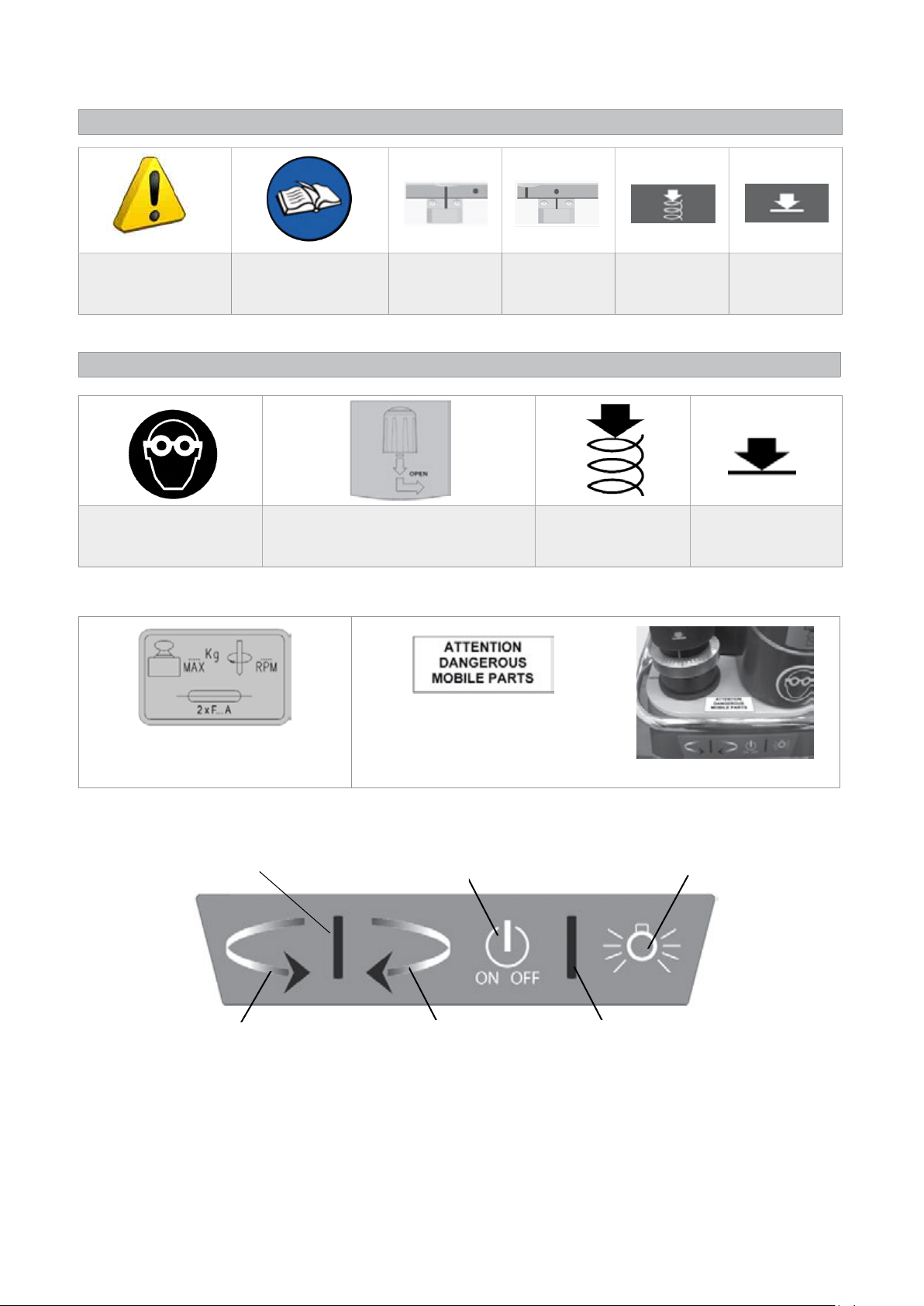

7.5 Work station description .................................................................................................................12

7.6 Starting the key-cutting machine ....................................................................................................13

7.6.1 Starting the motor.......................................................................................................................... 13

7.6.2 Cutter motor on warning light ........................................................................................................ 13

7.6.3 Led lamp (matrix pro version)........................................................................................................ 13

7.6.4 Led lamp (matrix evo version) ....................................................................................................... 13

8 MACHINE CALIBRATION AND REGULATION ..................................................................................14

8.1 Fitting and removing tools ..............................................................................................................14

8.2 Micrometer gauge...........................................................................................................................15

8.3 Calibration / tool alignment.............................................................................................................16

8.4 Tracer point spring..........................................................................................................................17

8.5 Carriage spring for laser keys.........................................................................................................18

8.6 Clamps ...........................................................................................................................................20

8.6.1 The clamp unit has several seats dedicated to the positioning of different types of keys: ............ 21

9 CUTTING............................................................................................................................................25

9.1 Fitting keys .....................................................................................................................................25

9.2 Key stop..........................................................................................................................................25

9.3 Cutting dimple keys ......................................................................................................................26

9.3.1 Back cuts ..................................................................................................................................... 26

9.3.2 Inclined cuts................................................................................................................................... 27

9.4 Cutting laser type keys ..................................................................................................................28

9.4.1 Cutting laser keys with narrow stems............................................................................................ 29

9.5 Cutting chet type keys (h prole) ..................................................................................................30