INDEX

REFERENCE GUIDE ...................................................................................................................1

GENERAL ....................................................................................................................................5

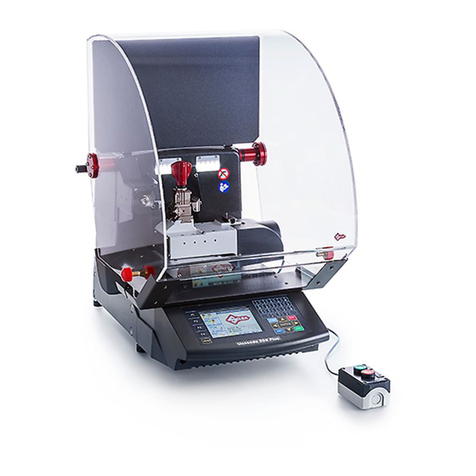

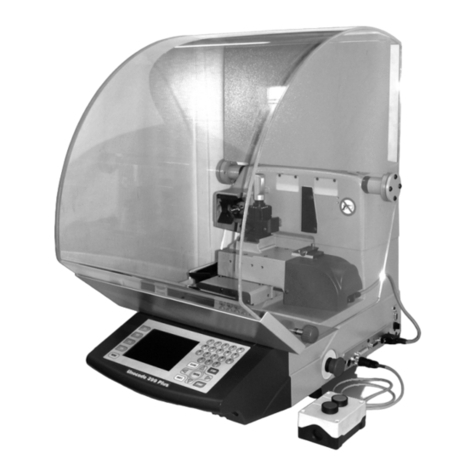

1 MACHINE DESCRIPTION ........................................................................................................6

1.1 Main characteristics ............................................................................................................... 6

1.2 Safety ..................................................................................................................................... 7

1.3 Main working parts ................................................................................................................. 8

1.4 Technical data ....................................................................................................................... 9

1.5 Accessories provided ........................................................................................................... 10

2 TRANSPORT ..........................................................................................................................11

2.1 Packing ................................................................................................................................ 11

2.2 Unpacking ............................................................................................................................ 11

2.3 Machine handling ................................................................................................................. 12

3 MACHINE INSTALLATION AND PREPARATION .................................................................13

3.1 Checking for damage ........................................................................................................... 13

3.2 Environmental conditions ..................................................................................................... 13

3.3 Positioning and installation .................................................................................................. 13

3.4 Description of work station ................................................................................................... 13

3.5 Graphics .............................................................................................................................. 14

4 “SET UP” AND USE OF THE MACHINE ...............................................................................15

4.1 Keyboard and functions ....................................................................................................... 15

4.2 Use of the clamp .................................................................................................................. 16

4.3 Cutting by electric contact .................................................................................................... 17

4.4 Cutter ................................................................................................................................... 17

4.5 Changing the cutter ............................................................................................................. 17

5 USER’S GUIDE .......................................................................................................................18

5.1 Symbol and terminology ......................................................................................................18

5.2 Initial Operations .................................................................................................................. 18

5.3 [0] Copy from original........................................................................................................... 20

5.4 Copy from ORIGINAL for FRONT STOP - MALE ................................................................ 24

5.4.1 Reading keys with front stop (double bit, single bit - male) ........................................................24

5.4.2 Cutting keys with front stop (double bit, single bit - male) ..........................................................24

5.5 Copy from ORIGINAL for FRONT STOP - FEMALE ........................................................... 26

5.5.1 Reading keys with front stop (double bit, single bit - female) .....................................................26

5.5.2 Cutting front stop keys (double bit, single bit - female) ..............................................................27

5.6 Copy from ORIGINAL for CENTRE STOP .......................................................................... 28

5.6.1 Reading keys with centre stop (English type) ............................................................................28

5.6.2 Cutting keys with centre stop (English type) ..............................................................................29

5.7 FAS 309 Plastic Stem .......................................................................................................... 30

5.8 Adapter for cutting CHUBB keys with square section stems ............................................... 31

5.9 PUMP KEYS ........................................................................................................................ 32

5.10 MUEL PUMP KEYS .............................................................................................................35

5.11 FIAM KEYS .......................................................................................................................... 38

5.12 KEYS WITH REAR STOP (Male keys and Female keys) ................................................... 43

5.12.1 FRENCH REAR STOP KEYS.................................................................................................... 51

5.13 SMALL BIT / DOUBLE BIT KEYS ....................................................................................... 53

5.14 SPECIAL BIT FEMALE KEYS ............................................................................................. 57

5.15 POST-READING adjustments to make to the key after reading ......................................... 61

5.15.1 Front-rear bit conversion ............................................................................................................62

5.15.2 “X” Specular bit conversion ........................................................................................................ 62

5.15.3 Correcting bit depth ....................................................................................................................63

5.15.4 Bit construction ...........................................................................................................................64

5.16 Decode and copy ................................................................................................................. 66

5.17 Entering the cuts .................................................................................................................. 67

5.18 Use Of The Machine with a Personal Computer ................................................................. 70

5.19 Use of the Machine with OPTIKA via PC.............................................................................. 72