4

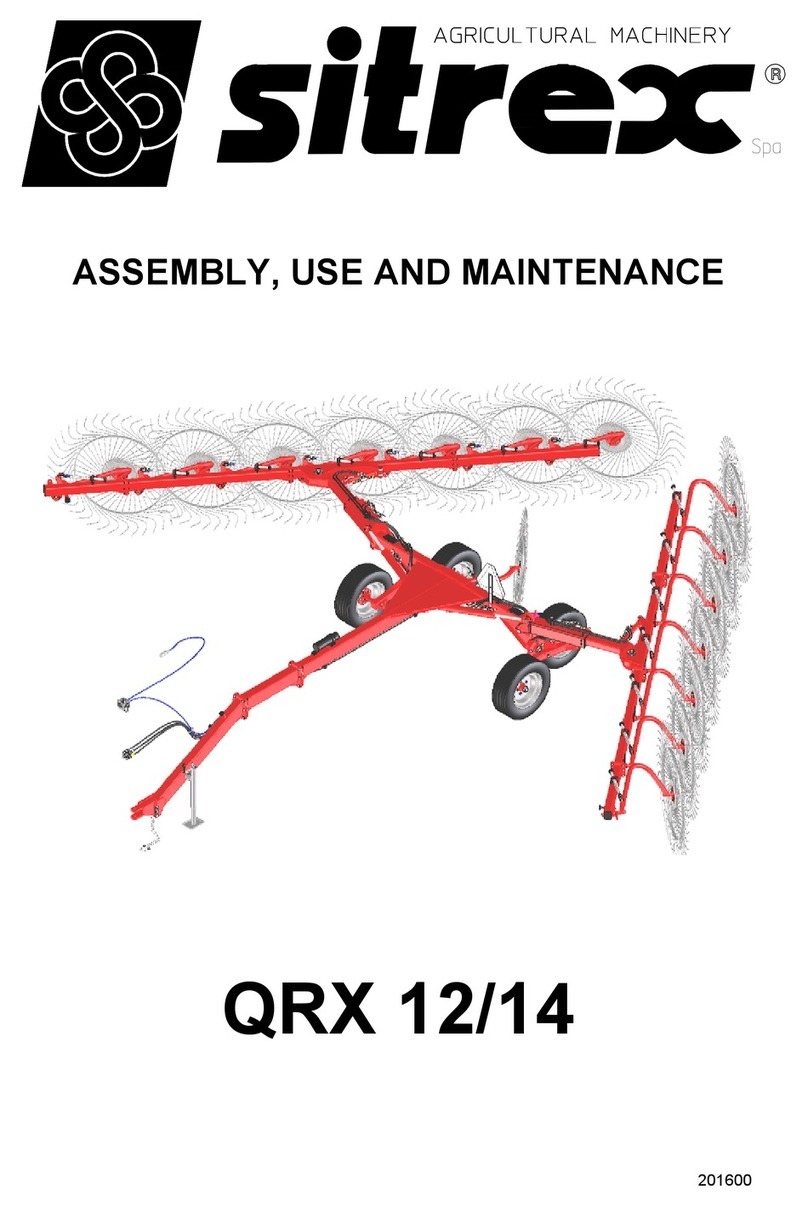

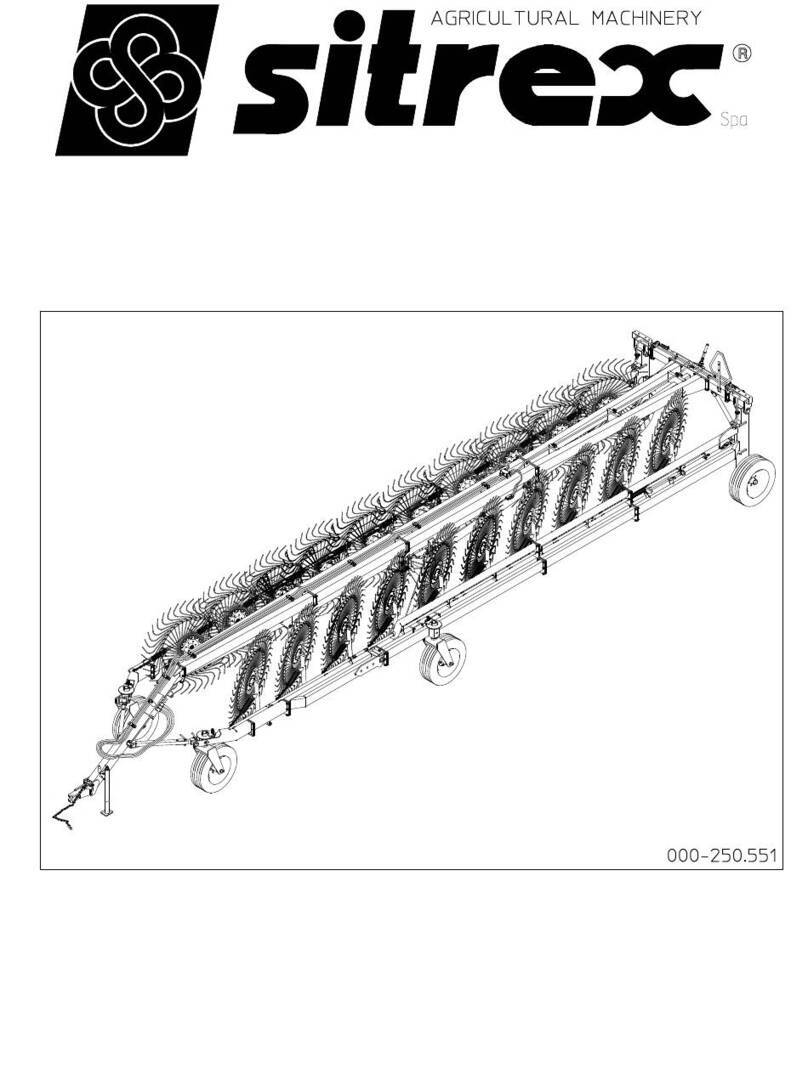

General assembly instructions for all models in the MK series.

As regards the indicating of

right/left, they are understood to be

attributed observing the machine

from point A (behind the machine)

looking forward.

The machine must be assembled in a suitable area, done by qualified personnel

equipped with the proper clothing, protective equipment and tools necessary for the

job. Only authorized persons should be in the assembly area.

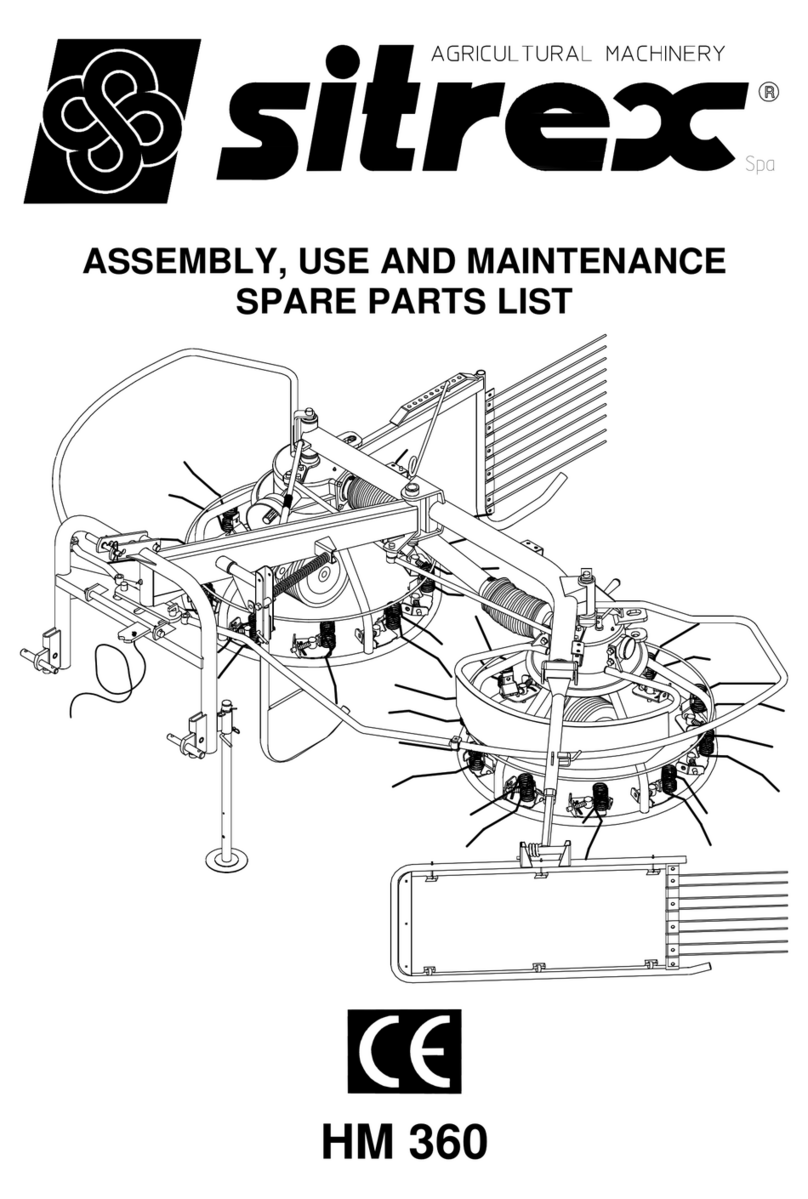

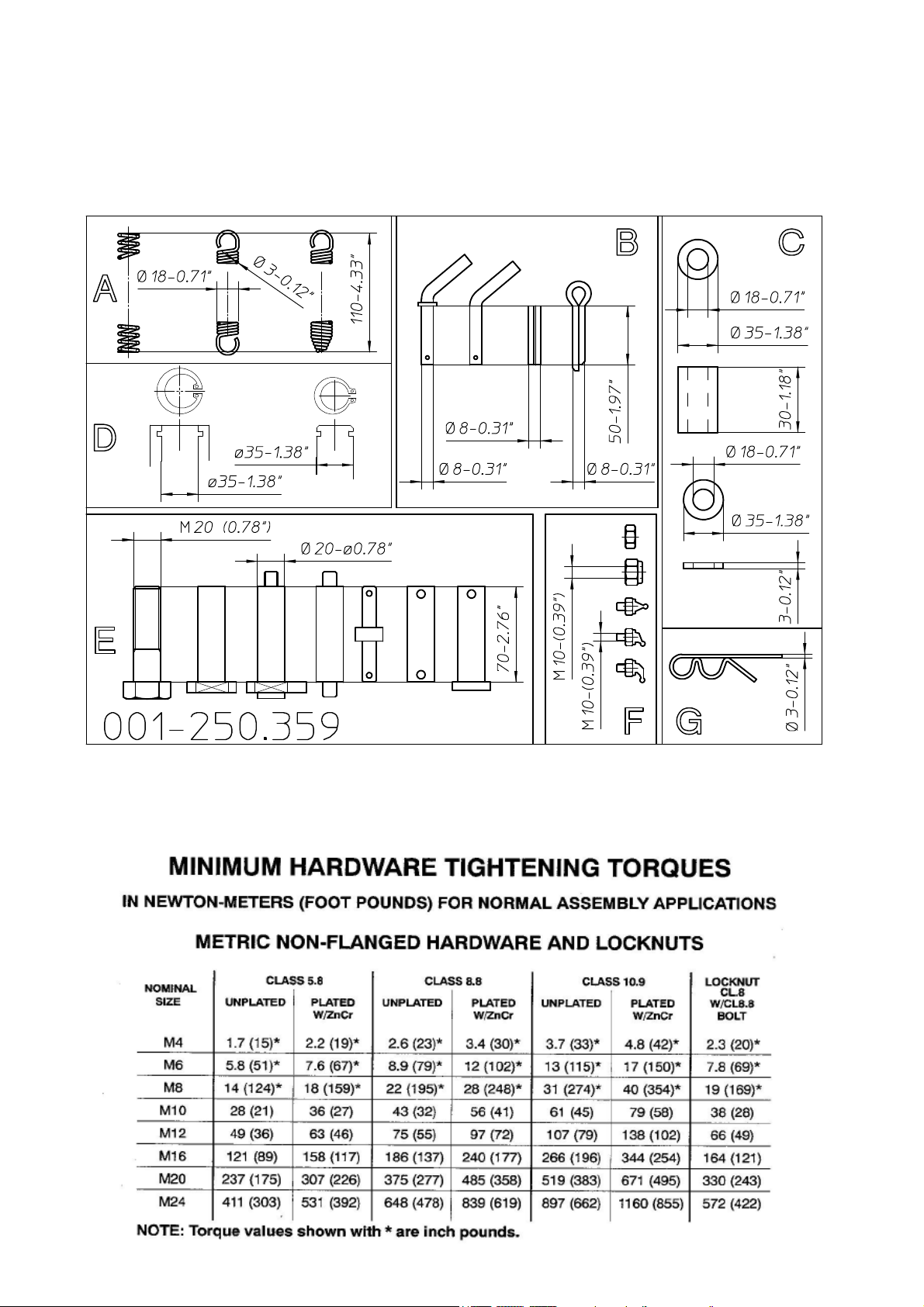

Assembly is correct when the various RH sections A, C, E, etc. and the various LH

sections B, D, F, etc. are aligned and parallel to each other and when the coupling

flanges G between one section and another are flush. NOTE: since these are sections

to be joined by means of welded flanges, there will not be perfect linearity between

RH sections A, C, E, etc. and LH sections B, D, F, thus a certain margin of error

must be tolerated. To reduce this error to a minimum, a few small techniques must

be used. For example, tighten the flange coupling bolts, one outside 1 and one inside

2, if the RH sections A, C, E, etc. and LH sections B, D, F, etc. are linear; or tighten

first the outside bolts 3-4 if the sections tend to curve toward the inside of the

machine, and vice versa tighten first the inside bolts 5-6 if the sections tend to curve

toward the outside.

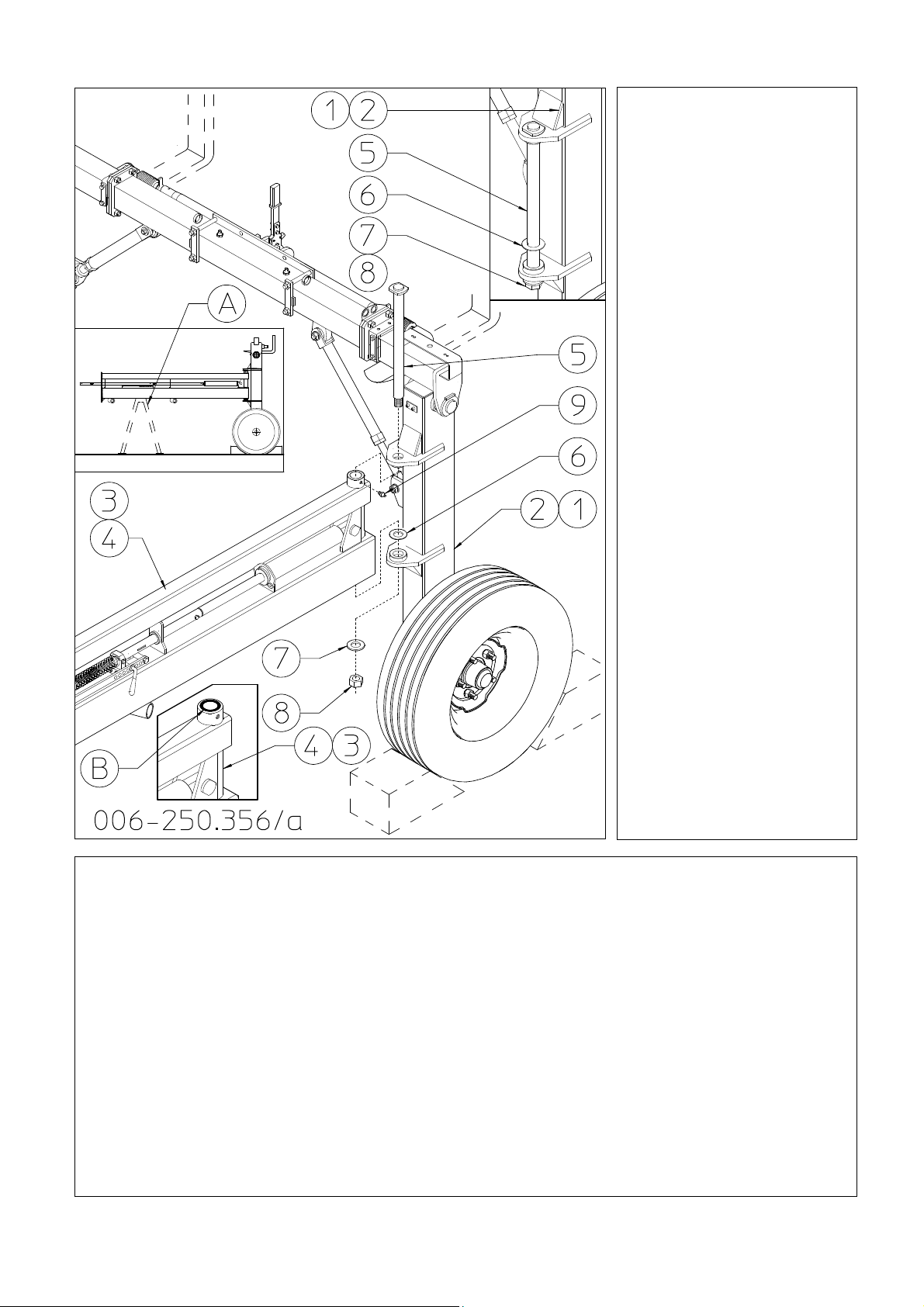

The alignment of the sections is important, as it also affects the assembly of the rake

wheel lifting pipes and how they slide along supports H during use. Bearing in mind

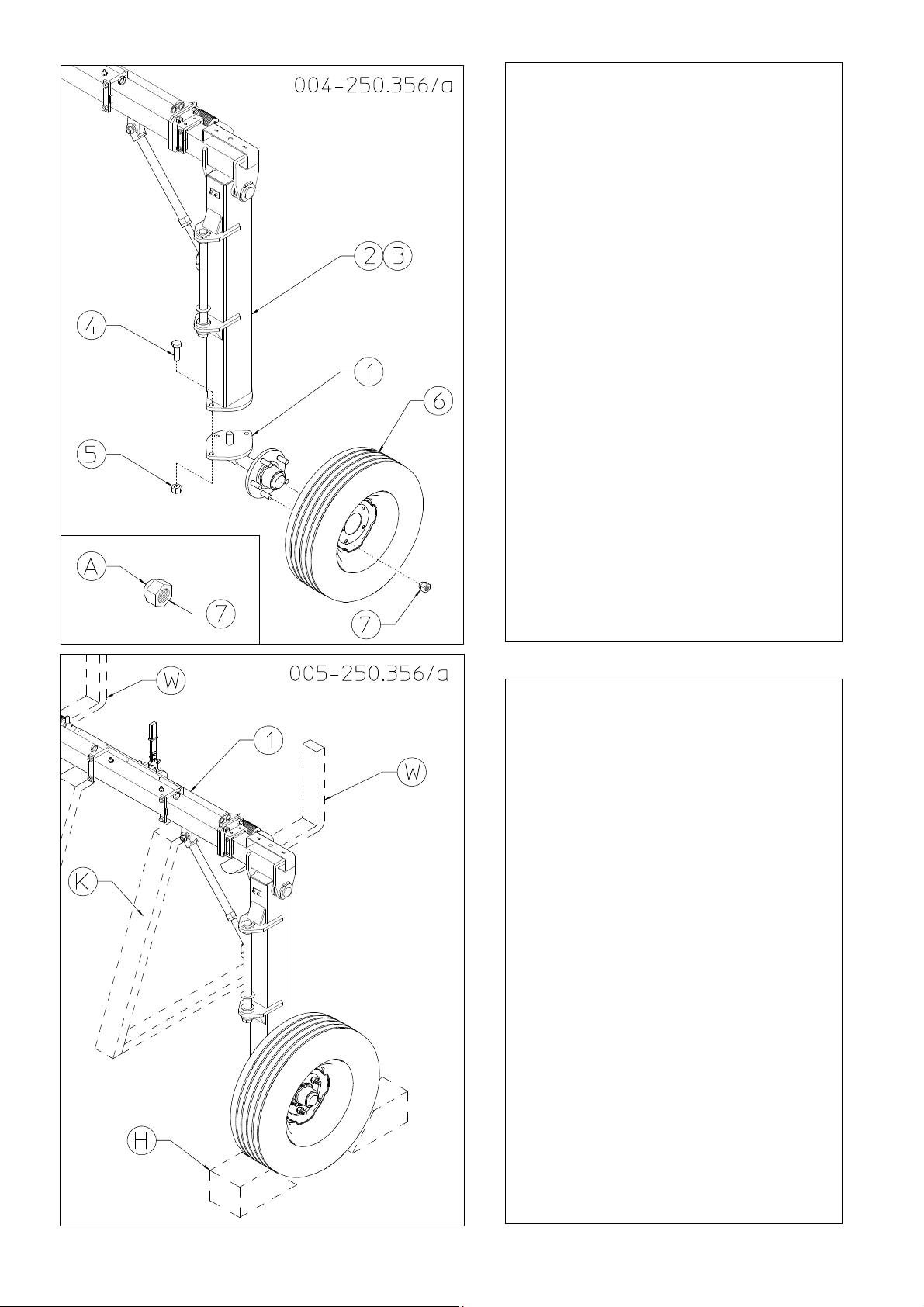

this advice, you can proceed with the assembly following the steps illustrated in

following. Unless otherwise specified, the assembly is shown for just one side of the

machine, but as it is symmetrical, simply repeat the same steps on the other side as

well. The quantities of the materials to be used for the various assembly steps refer

to both sides of the machine. The weights given near the major components may

vary by +/- 5%.

NOTE: What we are about to describe is an approximate assembly procedure. Each

person, based on their experience and on the tools they have to work with, may vary

the assembly steps to suit their needs. Always use great caution because the

assembly steps are dangerous.