ASSEMBLY, USE AND MAINTENANCE

2

SAFETY INFORMATION & WARNING

Always read your operators manual thoroughly before operating or performing any

maintenance on your mower. Before you operate this machine, know your controls and how to

stop the tractor and mower quickly in an emergency! Read and observe all safety decals on the

tractor and mower.

Use extreme caution and reduce speed when operating on hillside. Use cabs equipped with

ROPS (Roll Over Protection) and seat belts. Mowers are more likely to throw objects when

operating on hillside and tractors can easily tip. Either could result in serious injury to operator.

Never start or stop suddenly when going up or downhill. This could result in tipping of the tractor

or a roll-over. If steep slopes are anticipated, adjust the wheel width, add fluid to tires or add

tractor weights to compensate. Avoid steep slopes. Do not raise the cutter bar when mowing

hillsides. Doing so may increase the likelihood of tipping.

Only the operator should ride on the tractor no one should ride on the mower. Persons riding on

the tractor or the mower could easily fall into the path of the machine resulting in serious injury.

Anyone operating this machine must be instructed in the operation and capable of safe operation

of the unit. Never allow children to operate this machine!

Never use drugs or alcoholic beverages which can hinder alertness or coordination while

operating. Consult your doctor about operating this machine while taking prescription drugs.

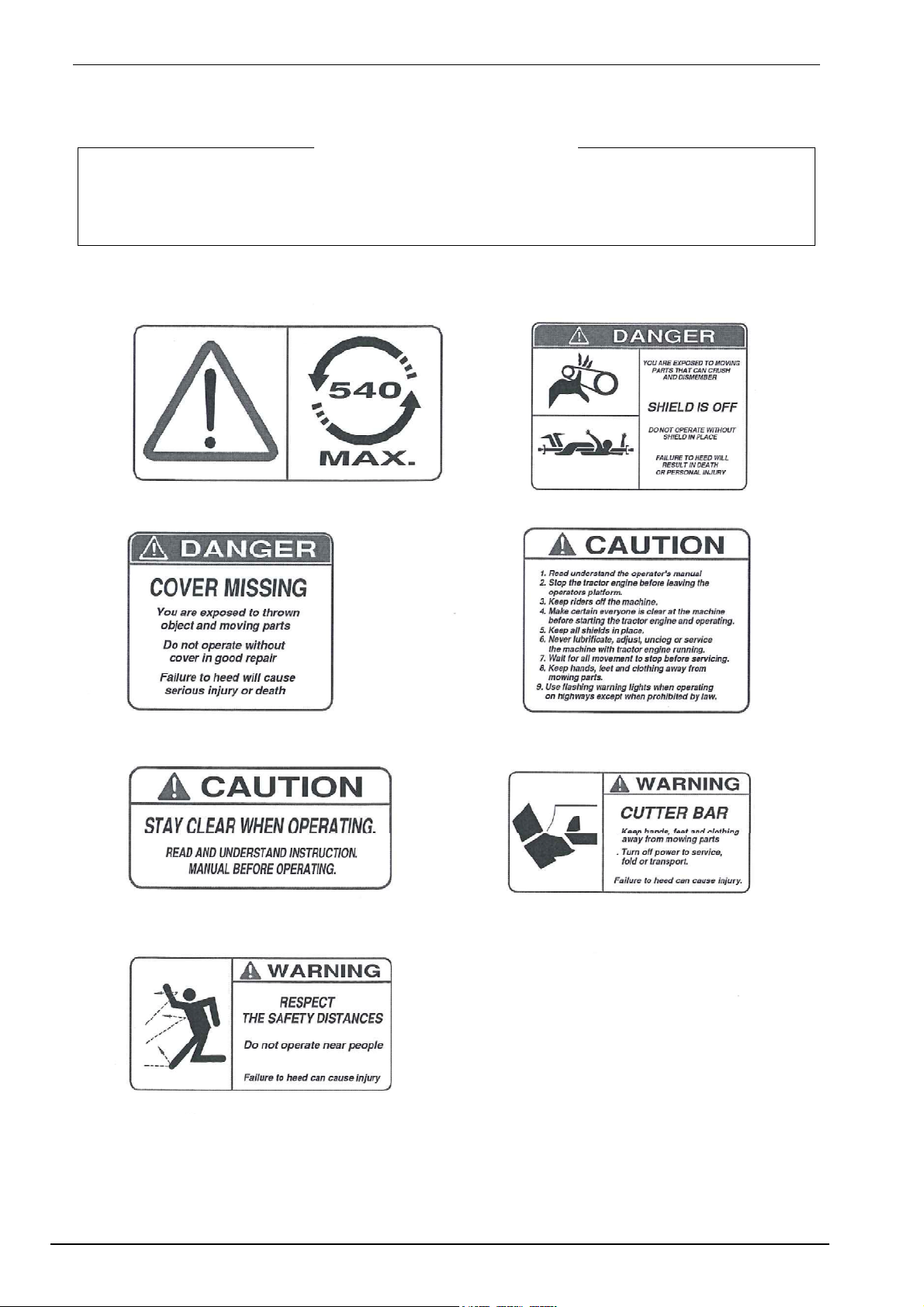

Always keep all covers, blades and guards, furnished with the machine, in place and in good

condition. Failure to do so could result in the operator being struck by high speed cutter bar. Keep

clear all mowing parts.

Make sure all onlookers personnel, children and pets are out of the area to be mowed. Make sure

pets and small children are not under or around the machine when you start the mower.

Always wear proper foot protection. Never operate the mower in bare feet or while wearing

sandals or sneakers.

Always operate in daylight conditions or use sufficient artificial lighting. Use extreme caution when

mowing under conditions which could hinder your ability to see people, pets or obstructions in the

mowing area.

Always check the drive line connections at the tractor and the gearbox before operation of the

mower. Be sure the quick disconnects are locked before operation.

Always disengage the tractor PTO and shift into neutral before starting the tractor.

Always lower the mower to the ground and shut off the tractor before dismounting and be sure

that the mowing motion has stopped

Failure to do so could result in the operator being injured by mowing tractor, mower or driveline

parts.